Automatic measuring and cutting device of board

An automatic measurement and cutting device technology, applied in metal processing and other directions, can solve problems such as inability to cut, and achieve the effect of ensuring cutting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

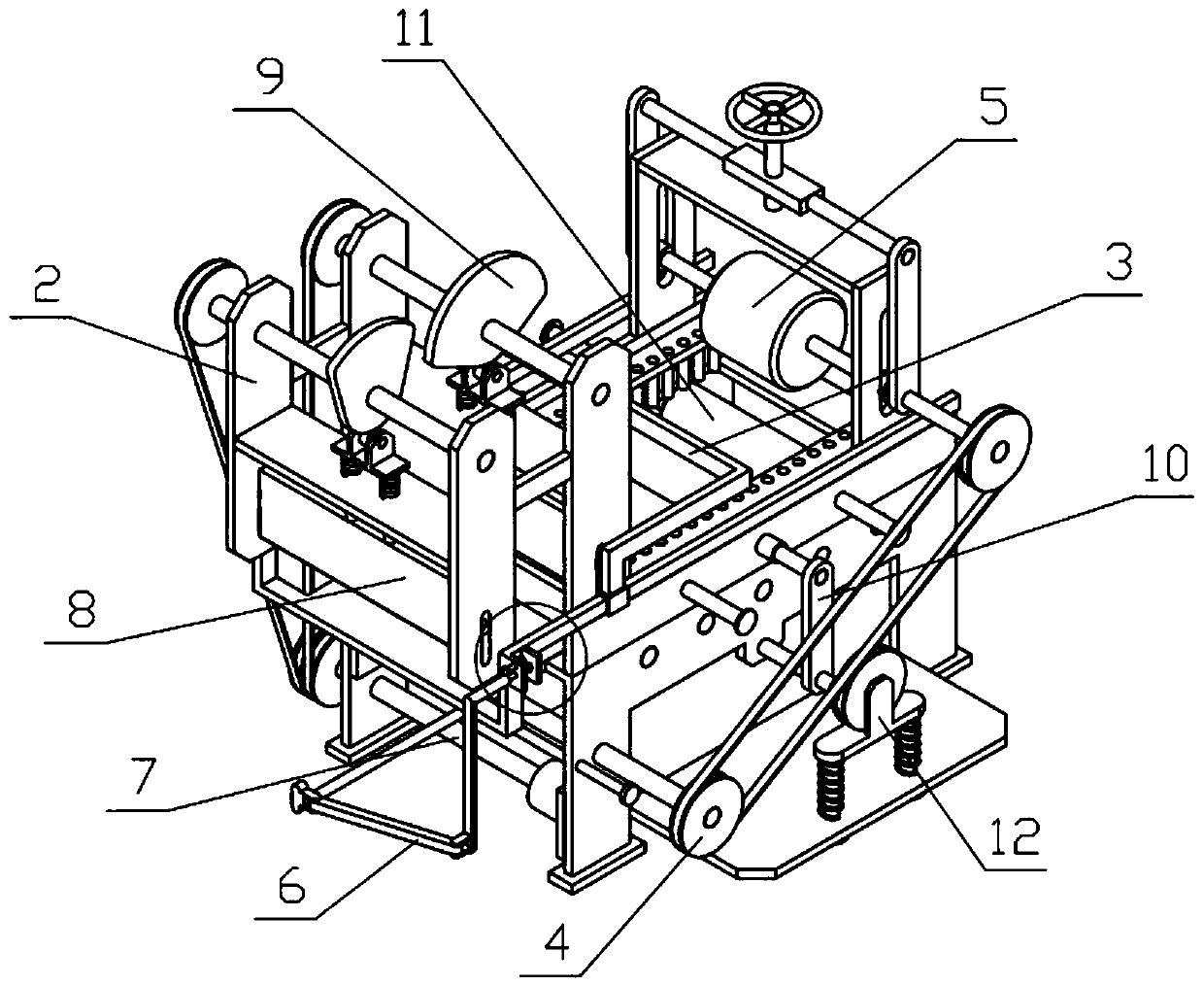

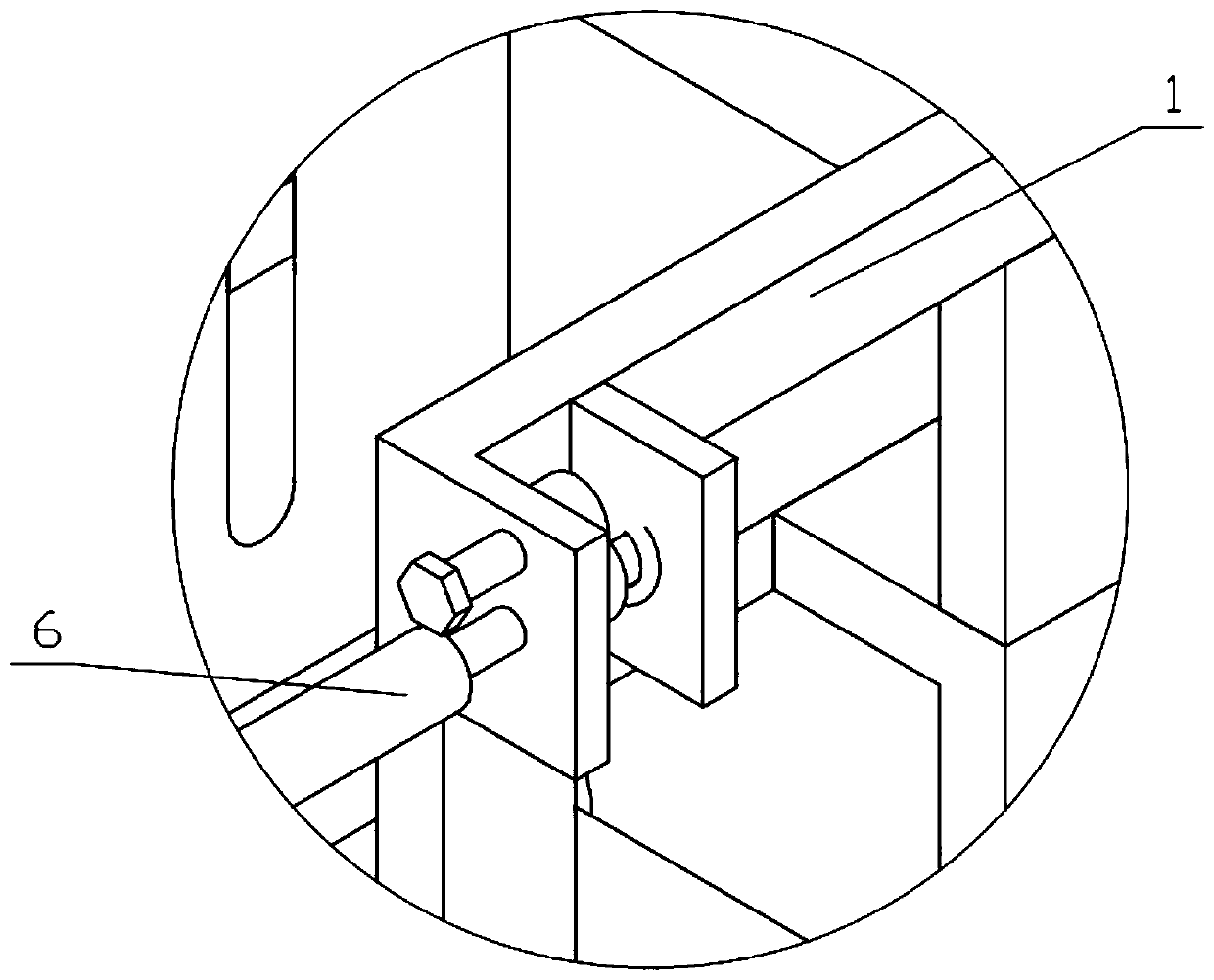

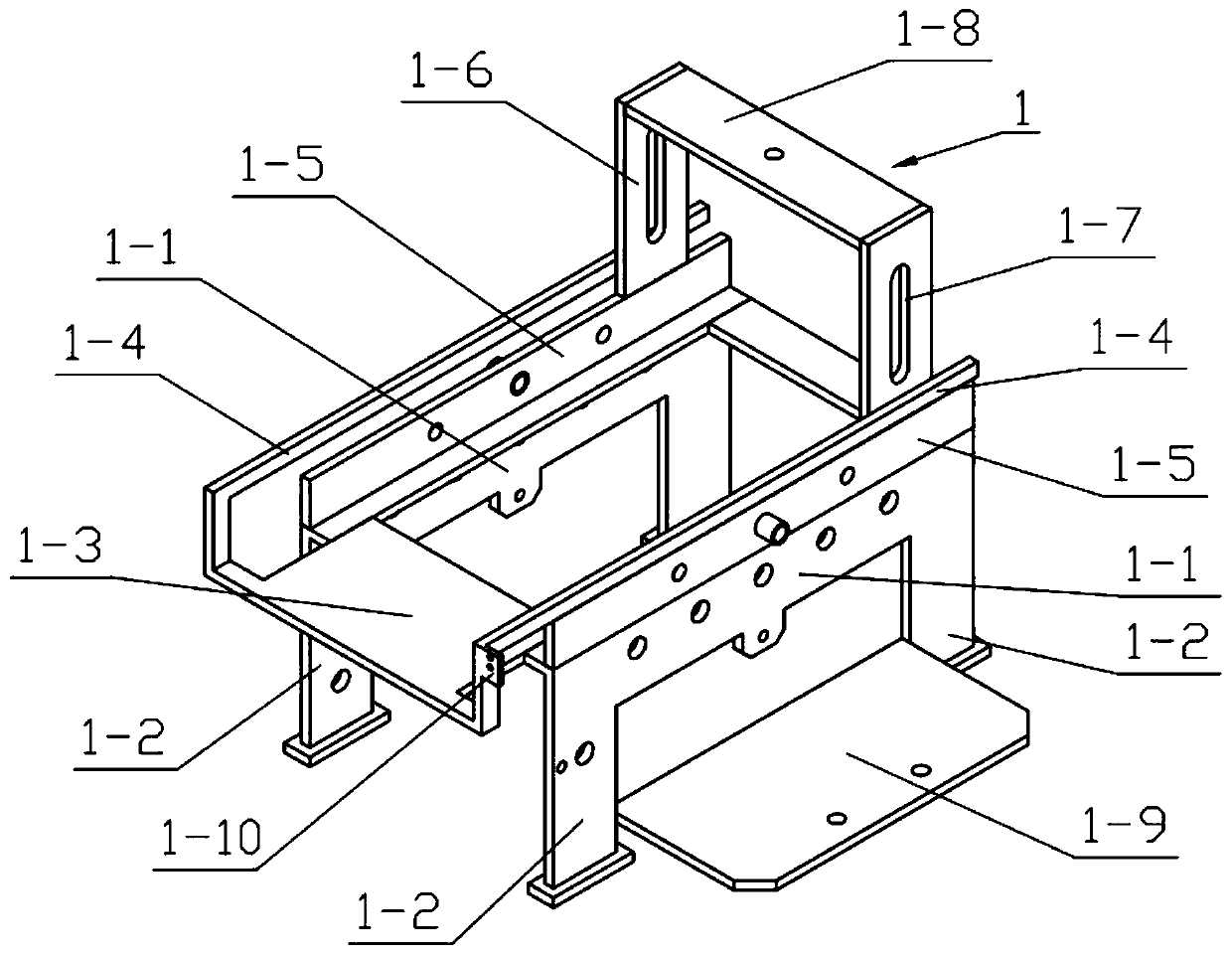

[0041] Combine below Figure 1-15 Describe this embodiment, an automatic measurement and cutting device for plates, including a device support 1, a cutting support 2, a measuring mechanism 3, a power mechanism I4, a pushing mechanism 5, a stop mechanism 6, a power mechanism II7 and a cutting mechanism 8, which can be measured by The two ends of the mechanism 3 are respectively slidably connected to the two measuring rulers 1-4 to measure the plate placed between the two support plates I1-1; The plate between 1 is pushed. When the plate moves the specified distance measured, the measuring mechanism 3 will push the stop mechanism 6 to move, and the stop mechanism 6 will cut off the power on the power mechanism I4, and the push mechanism 5 is not moving. The plate moves to the specified length, and the specified length of the plate is punched and cut through the cutting mechanism 8, and the pressing mechanism 9 clamps the plate during cutting to ensure that there will be no vibra...

specific Embodiment approach 2

[0051] Combine below Figure 1-15 This embodiment will be described, and this embodiment will further describe Embodiment 1. The device bracket 1 further includes a sliding plate 1-9, and the sliding plate 1-9 is fixedly connected between the two supporting feet 1-2 on one side.

specific Embodiment approach 3

[0052] Combine below Figure 1-15 Describe this embodiment, this embodiment will further explain the second embodiment, the cutting bracket 2 also includes a cutting support plate I2-2 and a vertical waist hole III2-7, and the two cutting side plates I2-1 are fixedly connected There is a cutting support plate I2-2, and the lower ends of the two cutting side plates I2-1 are provided with vertical waist holes III2-7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com