Noise reduction device and noise reduction method for steam pipeline purging

A steam pipeline and noise reduction technology, applied in chemical instruments and methods, cleaning methods and utensils, evaporators/condensers, etc., can solve the problems of unattainable noise indicators, time-consuming manufacturing processes, and high costs, and reduce noise reduction. The effect of cost, labor intensity reduction, energy saving and noise reduction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

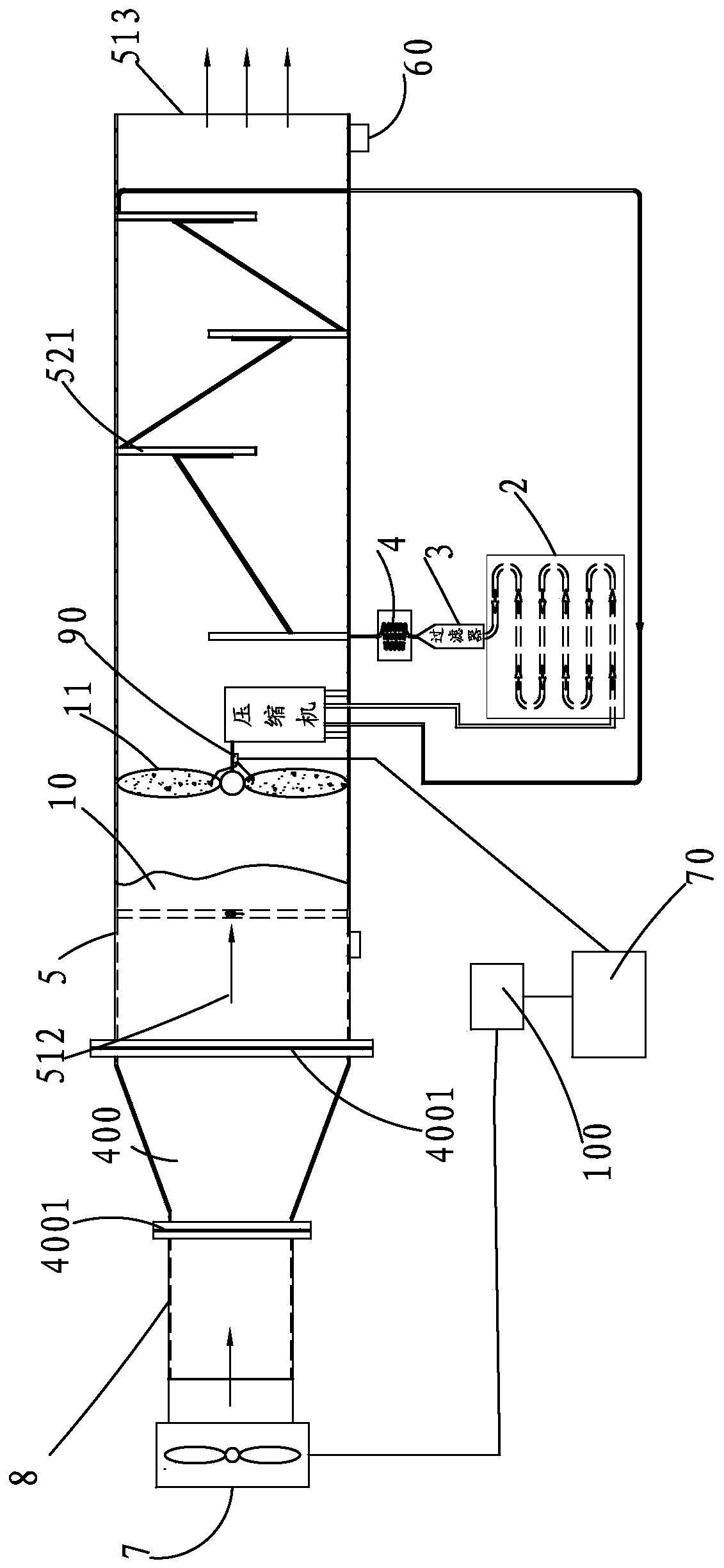

[0041] During work, the air outlet of fan 7 is connected to the inlet end of pipeline 8 to be cleaned, and the air outlet end of pipeline 8 to be cleaned is connected to the air inlet 512 by variable diameter connecting pipe 400; The high-temperature, high-pressure, and high-speed steam purges the pipeline, and the high-temperature, high-pressure, and high-speed steam first drives the fan blade 11 to rotate and perform work, which plays the role of noise reduction for the first time. In specific implementation, the fan blade 11 can be The turbine blades are adopted, and the blades 11 further drive the compressor 1 to move. The compressor 1 inhales and compresses the refrigerant into a high-temperature and high-pressure gaseous refrigerant, and then the compressor 1 delivers the gaseous refrigerant to the condensing In the condenser 2; the condenser 2 condenses the gaseous refrigerant and releases heat, and the high-temperature and high-pressure steam refrigerant becomes a low-t...

Embodiment 2

[0060] A noise reduction device for purging steam pipes, including a compressor 1, a condenser 2, a filter 3, a capillary 4, a first-stage expansion type noise reduction device 300, and a noise reduction module 5;

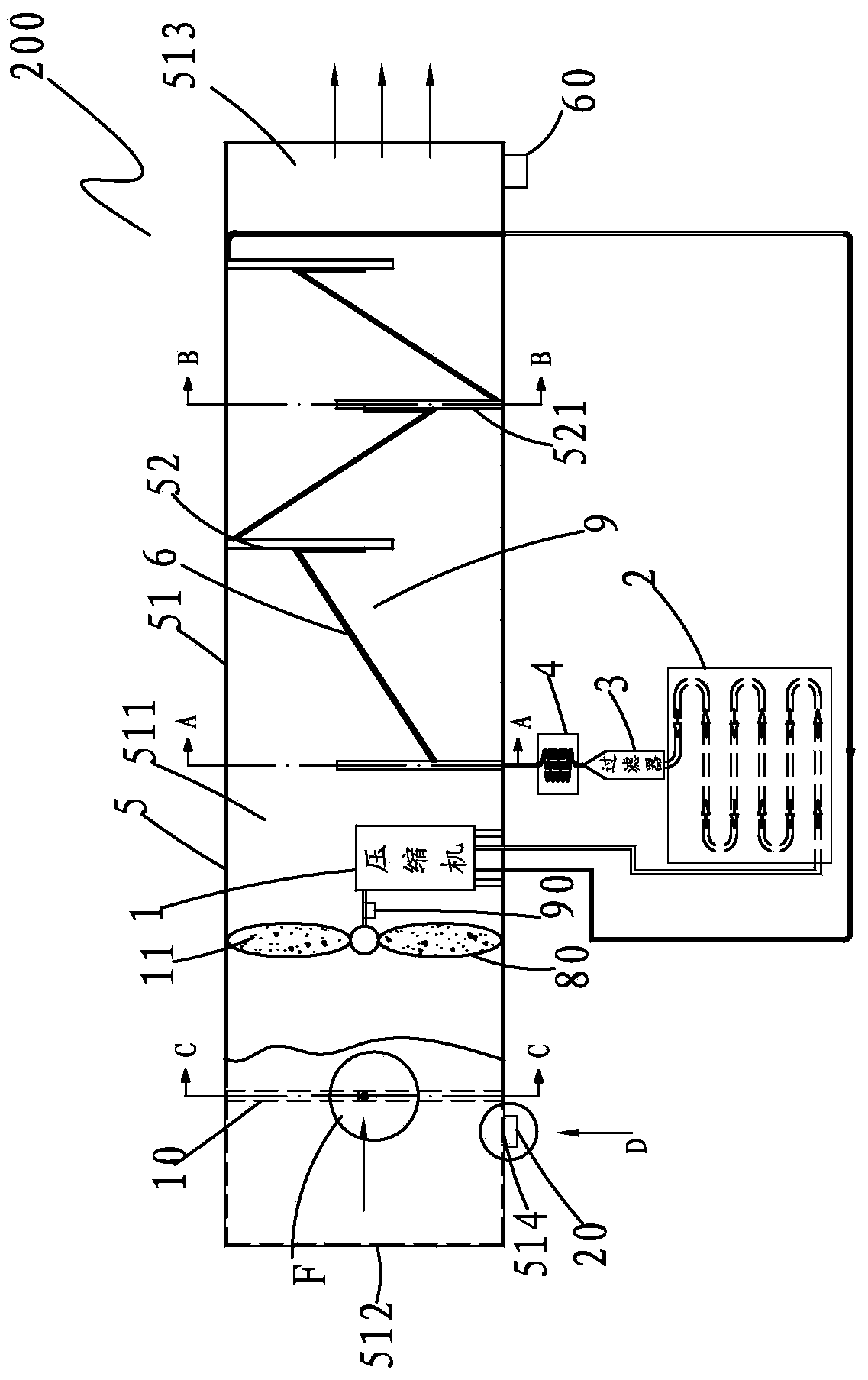

[0061] The noise reduction module 5 includes a noise reduction container 51 and a baffle type evaporator 52, the noise reduction container 51 is provided with a noise reduction cavity 511, and the noise reduction container 51 is also provided with an air inlet 512 and a An exhaust port 513, and the air inlet 512, the muffler chamber 511 and the exhaust port 513 are in communication with each other;

[0062] The compressor 1 is installed in the muffler cavity 511, and the fan blade 11 of the compressor 1 is arranged at the air inlet 512;

[0063] The baffle-type evaporator 52 includes a plurality of sound-absorbing baffles 521, which can be used as an evaporator to form a refrigeration cycle to cool down high-temperature, high-pressure, and high-speed steam, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com