Deposit monitor

A sediment and detector technology, applied in temperature measurement of moving fluid, instrument, heat measurement, etc., can solve time-consuming, heat exchanger surface can not maintain temperature, expensive and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

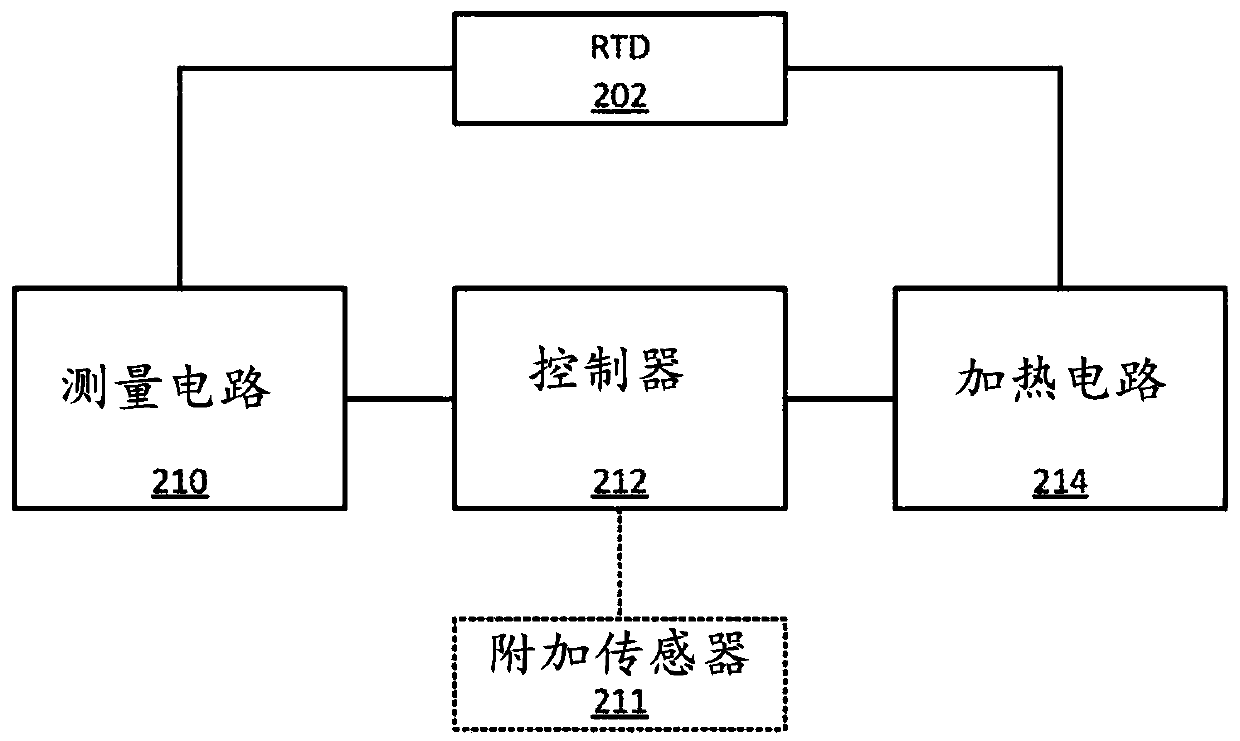

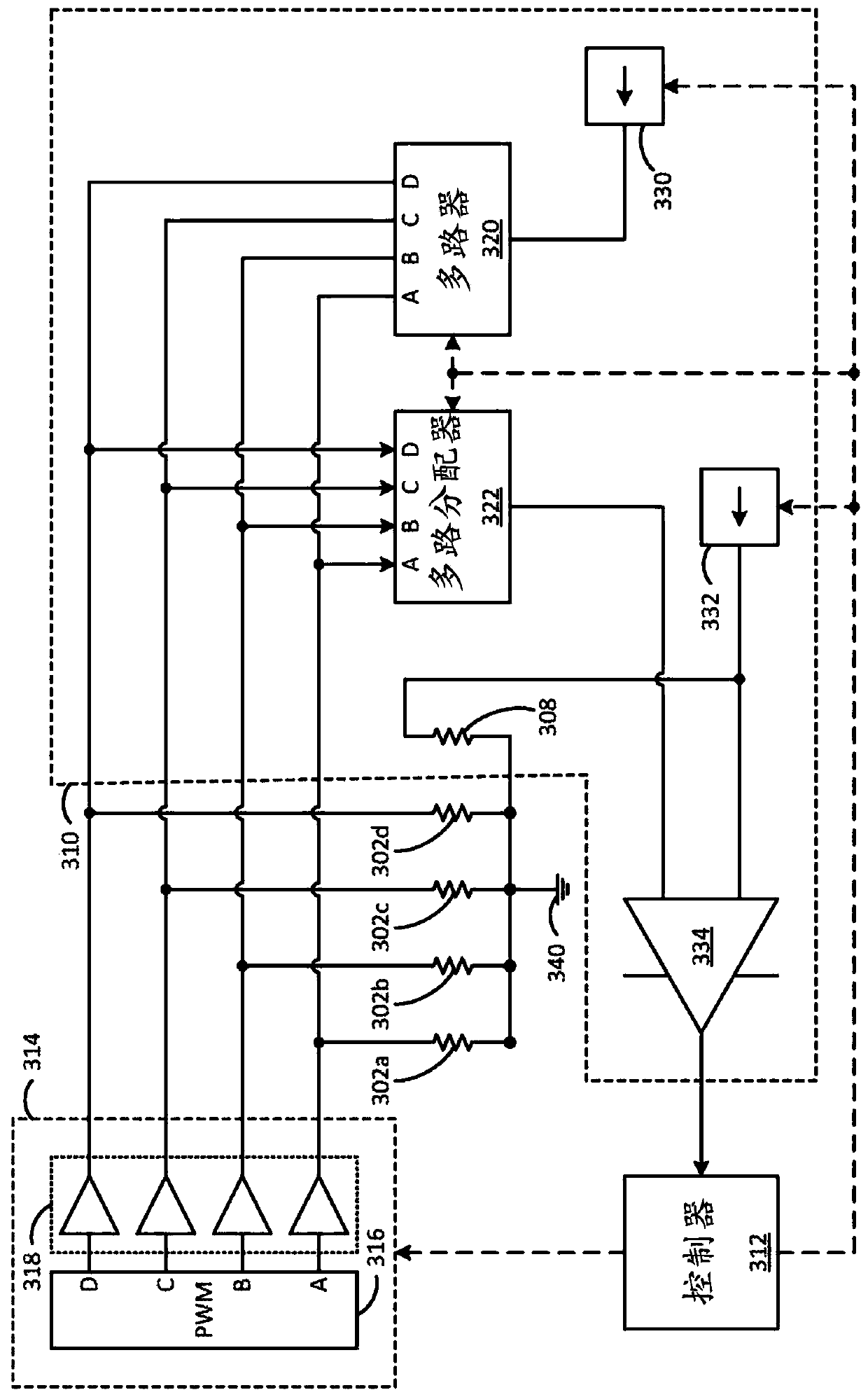

[0019] A resistance temperature detector (RTD) is a device commonly used to measure the temperature of an object of interest. For example, in some cases, an RTD's resistance is approximately linear with respect to temperature. Resistance can be measured by passing current through the RTD and measuring the voltage developed across the RTD. The current flowing through the RTD can have a heating effect on the RTD, so the current is usually kept at a relatively low magnitude during the temperature measurement. In exemplary operation, a small amount of current is passed through a conductor that is exposed to some environment whose temperature is to be measured. As the temperature changes, a characteristic change in resistance in the conductor (eg, platinum) is measured and used to calculate the temperature.

[0020] figure 1 is an illustration of an exemplary placement of one or more RTDs in a fluid flow system. As shown, RTDs 102a - d are positioned in a flow path 106 of a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com