continuous casting method for steel

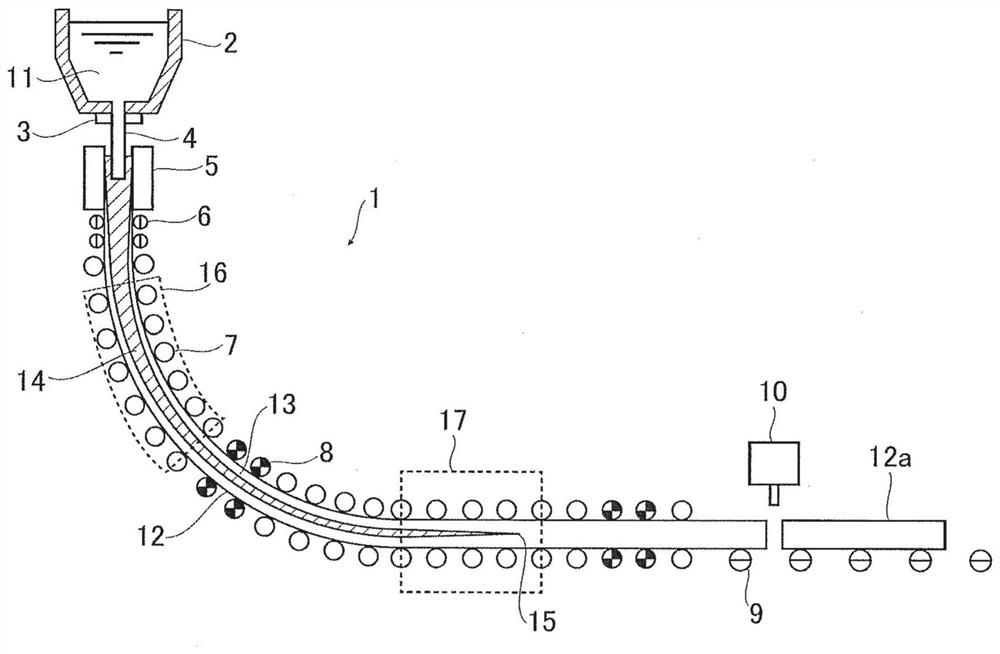

A technology for casting molds and casting pieces, applied in the field of continuous casting of steel, can solve the problems such as the limitation of the improvement effect of center segregation, and achieve the effect of improving internal quality, preventing cracks, and reducing the part that forms segregation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

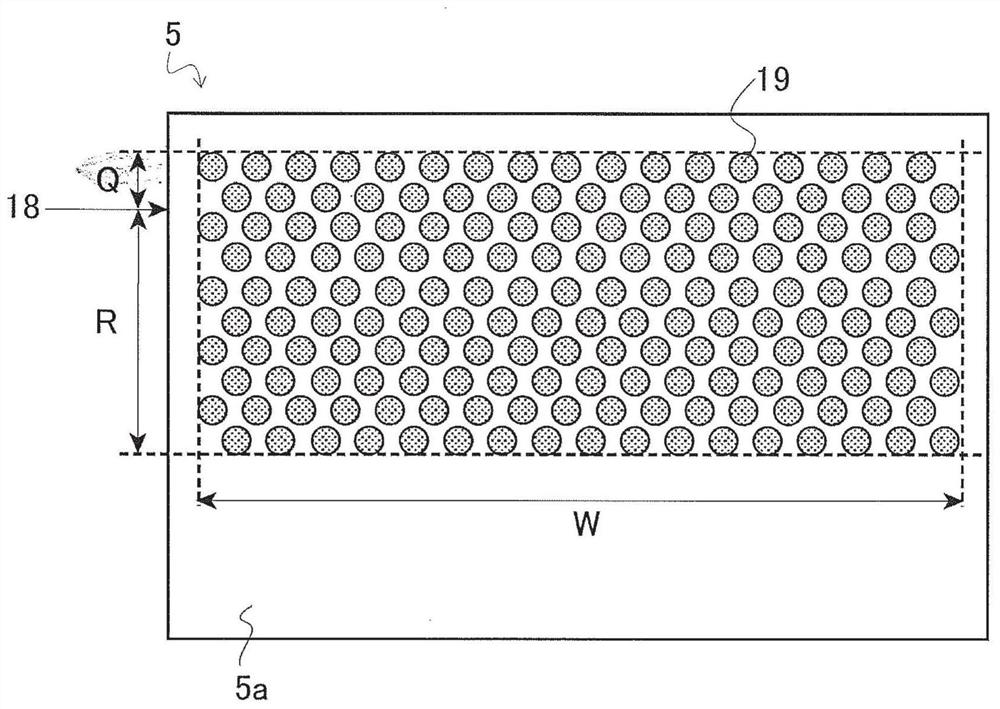

[0120] The following tests were carried out: using a water-cooled copper mold in which metal was placed on the inner wall under various conditions, and various tests were performed on the total belly volume in the forced belly belt and the product of the reduction speed and the casting speed in the soft reduction belt. Change, to cast medium carbon steel (chemical composition, C: 0.08-0.17 mass%, Si: 0.10-0.30 mass%, Mn: 0.50-1.20 mass%, P: 0.010-0.030 mass%, S: 0.005-0.015 mass% , Al: 0.020 to 0.040% by mass), and the surface cracks and internal quality (central segregation) of the cast slab after casting were investigated.

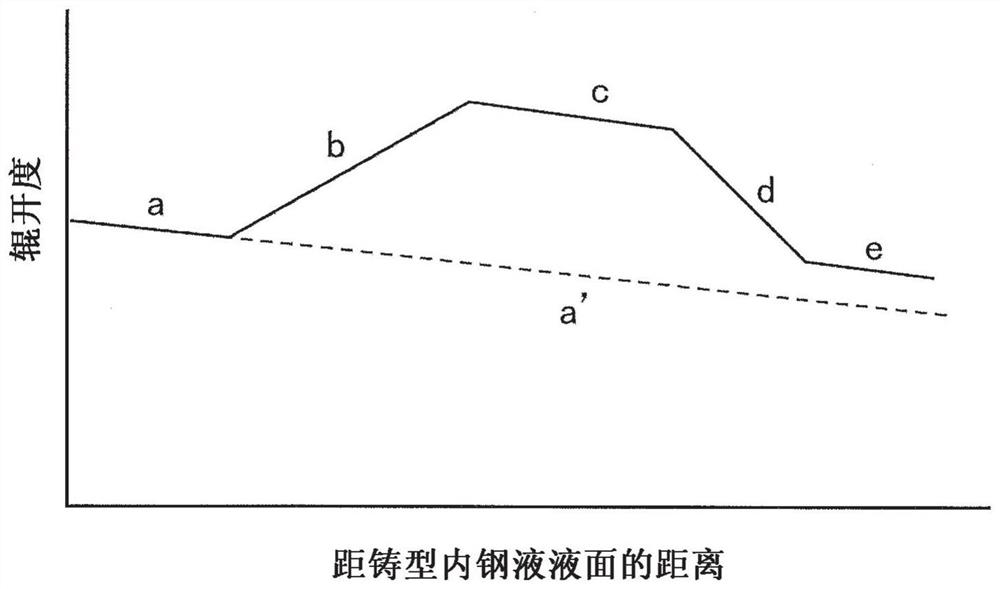

[0121] The product of the reduction speed in the soft reduction zone and the casting speed is 0.28~0.90mm·m / min 2 , in any of the tests, the slab was pressed from the time when the solid fraction in the center of the thickness of the slab was at least 0.2 to the time when it became 0.9 for the soft reduction zone. When the cast slab is forcibly bulged b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com