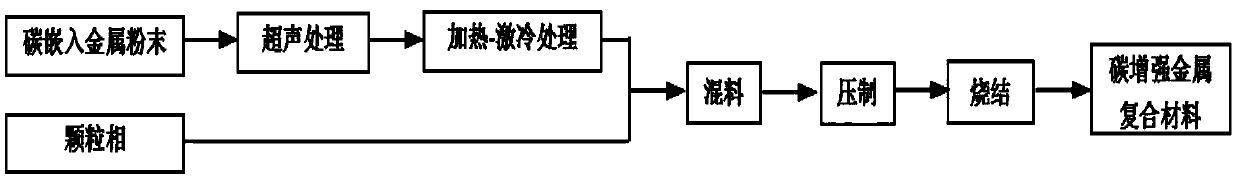

Preparation method of carbon-reinforced metal-based composite material

A composite material and metal-based technology, which is applied in the field of preparation of carbon-reinforced metal-based composite materials, can solve various problems such as unsatisfactory properties and poor compactness, and achieve the effects of low cost, improved sintering compactness and good wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] In Example 1, granular graphite and electrolytic copper powder are added together into ball milling equipment for high-energy ball milling. The particle diameter of the added electrolytic copper powder is 150 μm, and the particle diameter of granular graphite is 30 μm; the volume ratio of electrolytic copper powder and granular graphite is 5:1, the ball milling speed is 280r / min, the ball milling time is 8h, the ball milling balls are stainless steel balls, the ball diameter is 3mm~10mm (the mass ratio of ball milling ball diameters 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4 :8:11:20:12:8:6:1), the mass ratio of the sum of the mass of granular graphite and electrolytic copper powder to the ball milling ball is 1:6.

[0073] After the ball milling, mix the copper powder embedded with granular graphite with alcohol, add ultrasonic treatment for 120min (ultrasonic frequency is 35KHz), keep the temperature of the solution at room temperature, and then vacuum-dry the solution aft...

Embodiment 2

[0078] In Example 2, commercially available short carbon fibers were used as objects, and the short carbon fibers had a diameter of 7 μm and a length of 1 mm. Under vacuum conditions, keep warm at 700°C for 60 minutes for degumming treatment; then add electrolytic copper powder to the ball mill for high-energy ball milling, the particle size of the added electrolytic copper powder is 150 μm; the volume ratio of electrolytic copper powder to degummed short carbon fiber 3:1, the ball milling speed is 250r / min, the ball milling time is 6h, the ball milling balls are stainless steel balls, the ball diameter is 3mm~10mm (the mass ratio of ball milling ball diameters 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, 9mm is 4:8:11:20:12:8:6:1), the mass ratio of the sum of the mass of degummed short fiber and electrolytic copper powder to the ball milling ball is 1:6. The SEM morphology of the prepared carbon particles embedded in copper powder is as follows: figure 2 shown.

[0079] After ball millin...

Embodiment 3

[0084] In Example 3, commercially available short carbon fibers are used as objects, and the short carbon fibers have a diameter of 8 μm and a length of 2 mm. Dissolve the prepared phenolic resin in an organic solvent to obtain a phenolic resin alcohol saturated solution; then impregnate the short carbon fibers in an 80°C phenolic resin alcohol saturated solution for 2 hours; then dry at 120°C for 2 hours. Then add electrolytic nickel powder to the ball milling equipment for high-energy ball milling, the particle size of the added electrolytic nickel powder is 150 μm; the volume ratio of electrolytic nickel powder and degummed short carbon fiber is 4:1, the ball milling speed is 300r / min, the ball milling time The milling balls are stainless steel balls with a ball diameter of 3mm to 10mm (the mass ratio of ball milling ball diameters of 3mm, 4mm, 5mm, 6mm, 7mm, 8mm, and 9mm is 4:8:11:20:12:8:6: 1), the mass ratio of the sum of the mass of the phenolic resin-coated short fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com