Environment-friendly slowly-cured TPU hot melt glue film for insole and production method of environment-friendly slowly-cured TPU hot melt glue film

A technology of hot-melt adhesive film and production method, which is applied in the direction of adhesive, adhesive type, film/sheet without carrier, etc., can solve problems such as low lamination quality and glue hazards, so as to improve lamination quality and avoid Harmful, environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

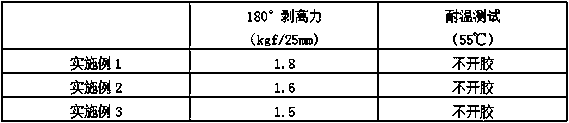

Embodiment 1

[0016] The hot melt adhesive film is prepared according to the following weight percentages and requirements of each component.

[0017] TPU particles: 60%, tackifying resin: 35%, functional additives: 5%. Among them, the hardness of TPU particles is 60-90A, the melting point is 50-100°C, and the melting index is 10-60g / 10min@150°C; the tackifying resin is C5 resin, and the softening point of the tackifying resin is 80-100°C, 160 The viscosity at ℃ is 1000-6000CPS; the functional auxiliary agent is antioxidant and ultraviolet absorber, and the weight percentage of antioxidant is 2%, and the weight percentage of ultraviolet absorber is 3%.

Embodiment 2

[0019] The hot melt adhesive film is prepared according to the following weight percentages and requirements of each component.

[0020] TPU particles: 70%, tackifying resin: 20%, functional additives: 7%. Among them, the hardness of TPU particles is 60-90A, the melting point is 50-100°C, and the melting index is 10-60g / 10min@150°C; the tackifying resin is C5 resin, and the softening point of the tackifying resin is 80-100°C, 160 The viscosity at ℃ is 1000-6000CPS; the functional auxiliary agent is an antioxidant and an ultraviolet absorber, and the weight percentage of the antioxidant is 3%, and the weight percentage of the ultraviolet absorber is 4%.

Embodiment 3

[0022] The hot melt adhesive film is prepared according to the following weight percentages and requirements of each component.

[0023] TPU particles: 80%, tackifying resin: 11%, functional additives: 9%. Among them, the hardness of TPU particles is 60-90A, the melting point is 50-100°C, and the melting index is 10-60g / 10min@150°C; the tackifying resin is C5 resin, and the softening point of the tackifying resin is 80-100°C, 160 The viscosity at ℃ is 1000-6000CPS; the functional auxiliary agent is an antioxidant and an ultraviolet absorber, and the weight percentage of the antioxidant is 4%, and the weight percentage of the ultraviolet absorber is 5%.

[0024] The production process of Example 1-3: first put the raw materials of each component into the extruder according to the weight percentage, and after extruding from the extruder, coat it on the release paper, and wind it up to make TPU hot melt film. Among them, the temperature settings of the extruder are as follows: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melt finger | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com