A kind of liquid metal conductive glue and its application

A technology of liquid metal and conductive adhesive, applied in the field of solar cells, can solve problems such as high welding temperature of ribbon, lower battery reliability, high solder paste welding temperature, etc., to increase output power, improve reliability, improve production efficiency and finished products rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Example 1 A liquid metal conductive adhesive for connection of photovoltaic shingled modules

[0058] This embodiment provides a liquid metal conductive adhesive for the connection of photovoltaic shingled components, which is composed of 30% matrix resin and 70% conductive filler by mass ratio; the conductive filler is composed of low melting point metal micronano powder and silver powder mixed, wherein The mass percentage of the low-melting point metal micro-nano powder is 80%, and the mass percentage of the silver powder is 20%.

[0059] Wherein, the matrix resin is composed of resin, curing agent, accelerator, coupling agent, diluent, defoamer, and antioxidant, and its mass-to-number ratio is 100:18:1.2:2:10:0.5:0.2;

[0060] The resin is prepared by mixing bisphenol A epoxy resin, novolak epoxy resin, polyester resin, and aliphatic multifunctional epoxy resin at a mass fraction ratio of 6:1:1:2.

[0061] Among them, the curing agent is methyl T-31 modified amine, ...

Embodiment 2

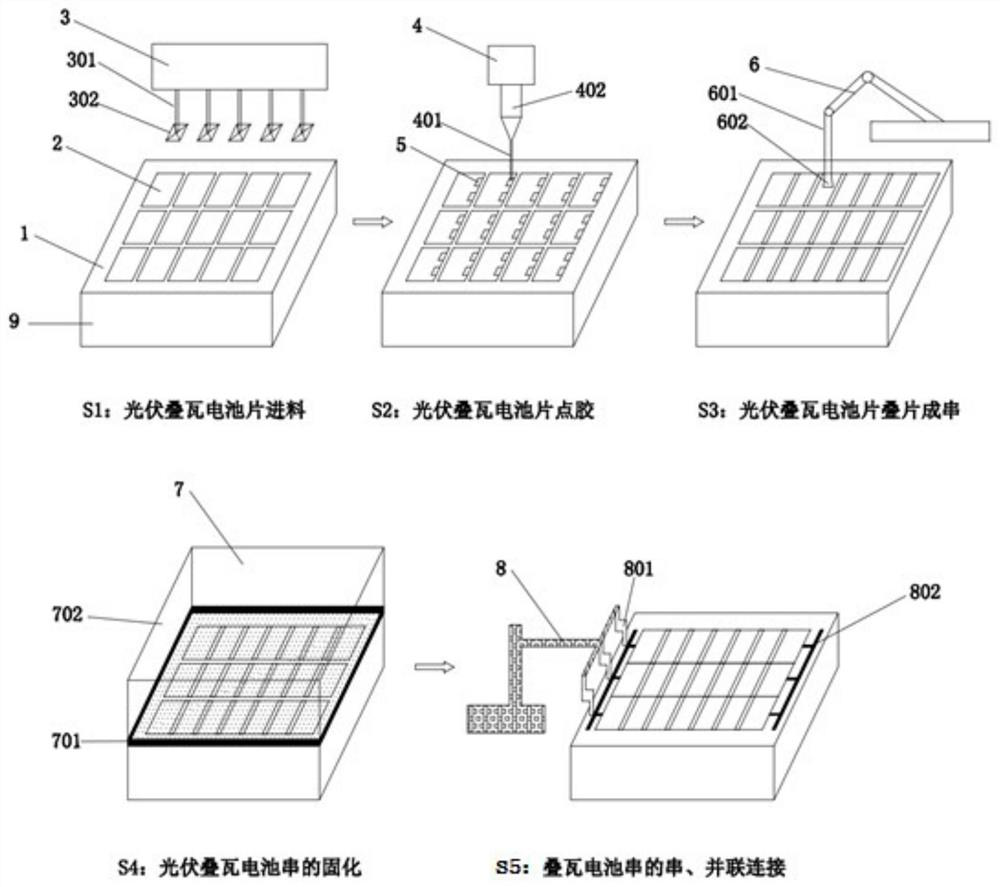

[0068] Example 2: A connection device for photovoltaic shingled modules

[0069] A connection device for photovoltaic shingled modules, such as figure 2 As shown, it includes: a heating platform 1, an array feeding device 3, a dispensing device 4, a stacking device 6, a closed curing device 7, a bus bar welding device 8, and a heating device 9;

[0070] Wherein, the heating platform is a movable flat plate, which can be placed between the array feeding device, the glue dispensing device, the stacking device, the closed curing device, and the bus bar welding device. Perform reciprocating movement to provide a working platform for each device.

[0071] The heating device is arranged below the heating platform, and the heating device moves together with the heating platform.

[0072] There is a battery substrate on the heating platform 1, which is used to heat and solidify the liquid metal conductive adhesive, so that the shingled battery sheets 2 form a conductive connection;...

Embodiment 3

[0079] Embodiment 3: A connection process using the photovoltaic shingled module described in Embodiment 1

[0080] A connection process for photovoltaic shingled components, such as figure 2 As shown, its technological process includes:

[0081] S1: Photovoltaic shingled cell feed;

[0082] S2: Photovoltaic shingled cell dispensing;

[0083] S3: Photovoltaic shingled cells stacked into strings;

[0084] S4: Curing of photovoltaic shingled battery strings;

[0085] S5: Several battery strings are welded in series and parallel to form photovoltaic shingled modules.

[0086] In the above S1, when the shingled components need to be connected, the shingled battery sheet 2 is transported to the battery substrate of the heating platform 1 through the array feeding device 3;

[0087] In the above S2, use the glue dispensing device 4 to apply liquid metal conductive glue at the welding point 5 on the edge of the battery sheet 2 with a thickness of 2 mm;

[0088] In the above S3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com