High content inorganic powder modified filler masterbatch

A technology of inorganic powder and filler masterbatch, which is applied in the field of high-content inorganic powder modified filler masterbatch, which can solve the problems of low tensile strength, elongation at break, etc., and achieve improved efficiency, high energy consumption, The effect of energy consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

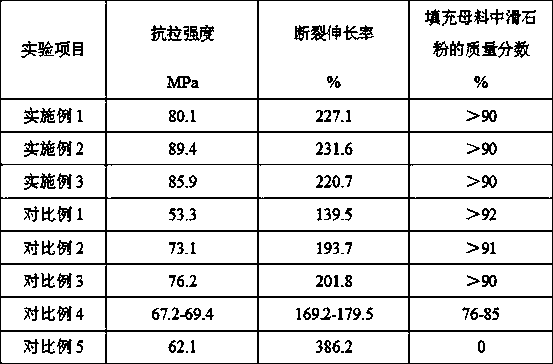

Examples

preparation example Construction

[0034] The preparation method of the described high-content inorganic powder modified filler masterbatch comprises the following steps:

[0035] S1: Soak the inorganic powder with a particle size of 0.1-6 μm in the inorganic mixed acid, the inorganic mixed acid is sulfuric acid with a concentration of 13-15wt%, phosphoric acid with a concentration of 24-30wt%, nitric acid with a concentration of 16-22wt% A mixed acid composed of a volume ratio of 3-5:2-4:2-3 is soaked for 2.5-3 hours and then dried at a temperature of 102-105°C for 4-6 hours to obtain a pretreated inorganic powder;

[0036] S2: Grinding the pretreated inorganic powder prepared in step S1 into a powder with a particle size of 1-60 nm;

[0037] S3: Add the powder and siloxane prepared in step S2 into a high-speed mixer, and stir for 20-35min at a speed of 3000-5000r / min and a temperature of 130-140°C to obtain pre-modified siloxane Processed powder;

[0038] S4: Add trifluorobromopropylene monomer to the silox...

Embodiment 1

[0042] A high-content inorganic powder modified filler masterbatch, which includes the following raw materials in parts by weight: 93 parts of inorganic powder, 5 parts of elastomeric materials, 1.6 parts of graft compatibilizer, 0.6 parts of dispersant, silicon oxide 0.8 parts of alkane, 1.2 parts of trifluorobromopropene monomer;

[0043] The elastomer material is pentametallic polyethylene;

[0044] Described inorganic powder is talcum powder;

[0045] The particle size of the talcum powder is 0.2-5 μm;

[0046] Described graft compatibilizer is PP-g-MAH compatibilizer;

[0047] Described dispersant is oxidized polyethylene wax;

[0048] The siloxane is γ-aminopropyltriethoxysilane;

[0049] The preparation method of the described high-content inorganic powder modified filler masterbatch comprises the following steps:

[0050] S1: Soak the inorganic powder with a particle size of 0.2-5 μm in an inorganic mixed acid, the inorganic mixed acid is sulfuric acid with a concen...

Embodiment 2

[0056] A high-content inorganic powder modified filler masterbatch, which includes the following raw materials in parts by weight: 106 parts of inorganic powder, 6 parts of elastomer material, 2 parts of graft compatibilizer, 1 part of dispersant, silicon oxide 1 part of alkane, 1.5 parts of trifluorobromopropene monomer;

[0057] The elastomer material is pentametallic polyethylene;

[0058] Described inorganic powder is talcum powder;

[0059] The particle size of the talcum powder is 0.1-4 μm;

[0060] Described graft compatibilizer is PP-g-MAH compatibilizer;

[0061] Described dispersant is oxidized polyethylene wax;

[0062] The siloxane is γ-aminopropyltriethoxysilane;

[0063] The preparation method of the described high-content inorganic powder modified filler masterbatch comprises the following steps:

[0064] S1: Soak the inorganic powder with a particle size of 0.1-4 μm in an inorganic mixed acid, the inorganic mixed acid is sulfuric acid with a concentration ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com