Preparation method and application of lead ion imprinted material

A technology of imprinted materials and lead ions, which is applied in the field of preparation of lead ion imprinted materials, can solve the problems of unsatisfactory results, matrix interference, low lead, etc., and achieve the effect of avoiding the damage of recognition sites and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of lead ion imprinted polymer

[0023] (1) Mix 1 mmol of lead acetate and 1-6 mmol of surfactant micelles with 1 mol of high-purity water, and stir at room temperature for 1 h;

[0024] (2) In the solution of step (1), add 1 to 6 mmol of functional monomer, and stir at room temperature for 1 hour to form a lead ion complex; the functional monomer is 3-mercaptopropyltrimethoxysilane;

[0025] (3) Dissolve 10-20mmol tetraethyl orthosilicate in 2-10ml methanol, mix with the solution in step (2), add 2-5mL sodium hydroxide solution, and stir magnetically at room temperature for 24-48h , and then reacted in a water bath at 90°C for 24 hours to form a polymer;

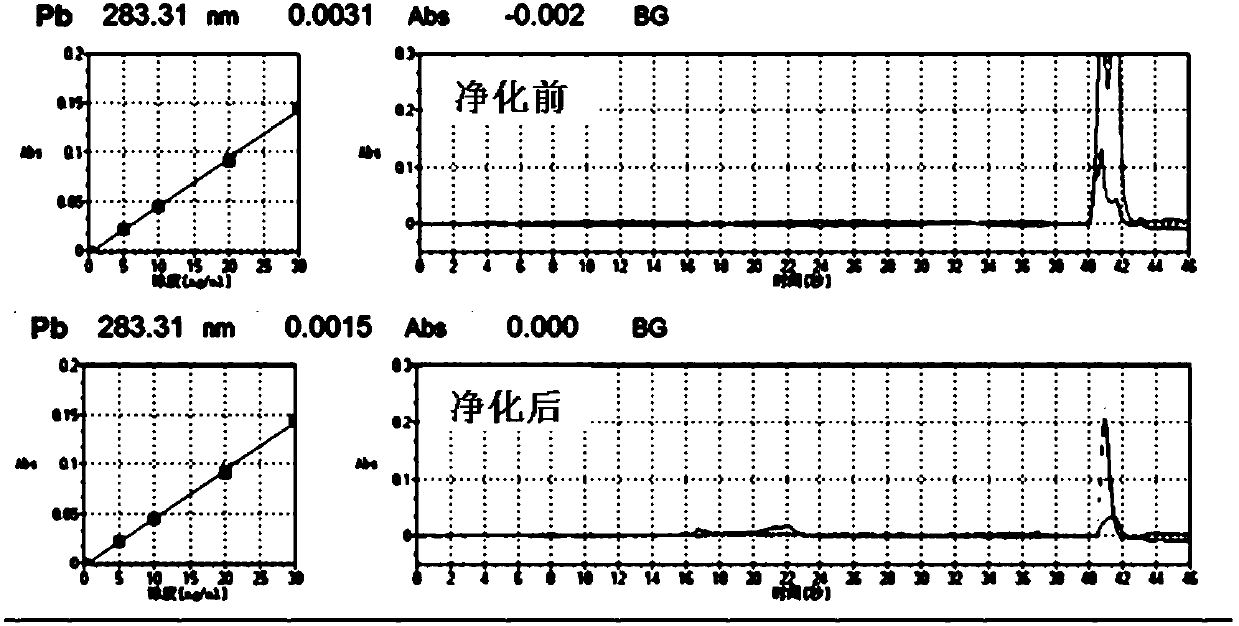

[0026] (4) The polymer formed in the step (3) is carried out in ethanol solution for 24h, and then washed repeatedly with 2mol / L nitric acid solution, until no lead ion is detected in the eluent, and finally washed with high-purity water until Neutral, oven dry.

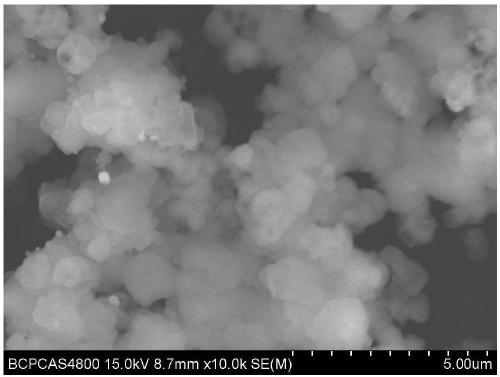

[0027] The lead ion-imprinted polymer p...

Embodiment 2

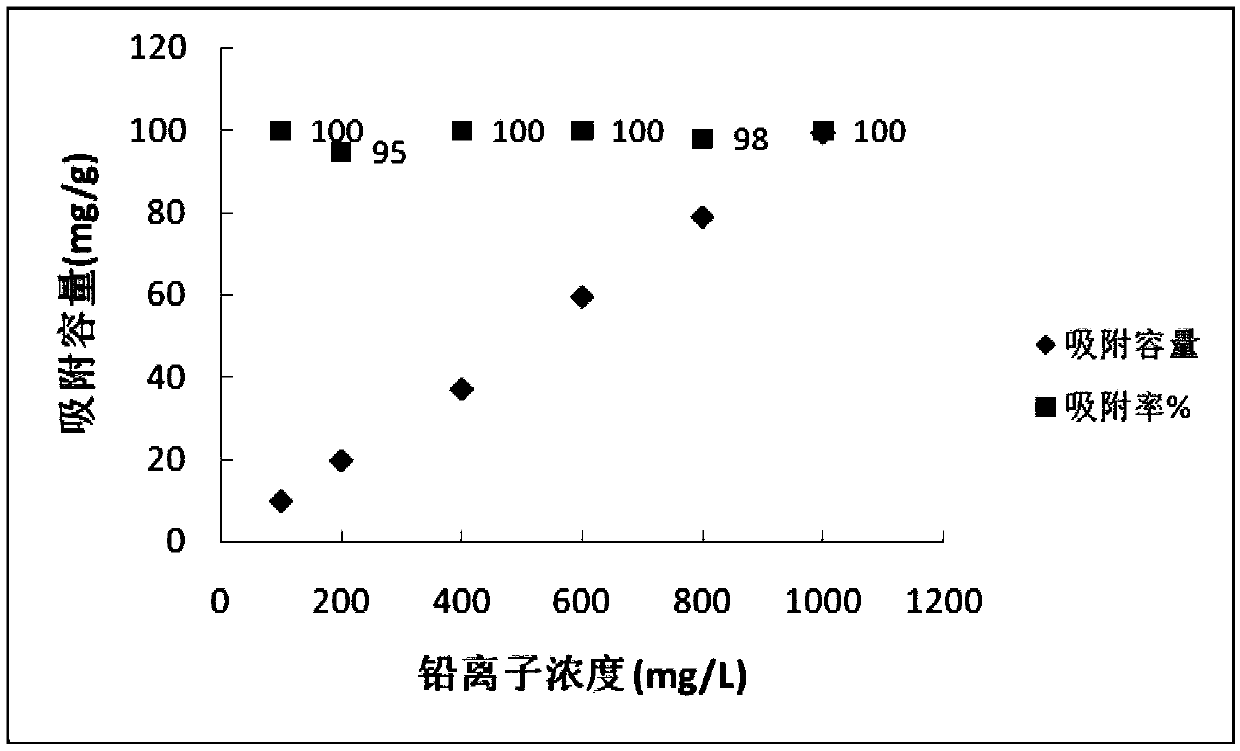

[0029] Adsorption Capacity of Lead Ion Imprinted Polymer

[0030] Accurately weigh multiple portions of 100 mg of lead ion-imprinted polymers into a 15 mL centrifuge tube, add 10 mL of lead ion solutions (100-600 μg / ml) with different concentrations, shake for 0.5 h, centrifuge, and use an atomic absorption spectrometer to measure the concentration of the supernatant. concentration of lead ions in the solution. Such as figure 1 As shown, the results show that the adsorption capacity of the lead ion-imprinted polymer is 55.64 μg / mg, which has good adsorption performance.

Embodiment 3

[0032] Selective Adsorption Assay of Lead Ion Imprinted Polymers

[0033] Accurately weigh 100 mg of the lead ion-imprinted polymer prepared in the example in a 15 mL centrifuge tube, add 10 mL of a solution containing lead ions and competing ions (such as cadmium ions, mercury ions), shake for 0.5 h, centrifuge, and detect the adsorption of the supernatant After the concentration of lead ions in the solution, add 10ml of 2M nitric acid solution to the precipitate, shake for 0.5h, centrifuge, and take the supernatant to detect the concentration of lead ions in the solution after elution.

[0034] Table 1 shows the competitive adsorption results of lead ion-imprinted polymers for different concentrations of cadmium(II) and mercury(II). It can be seen that the adsorption rate of the lead ion-imprinted polymer to template lead ions is much higher than that of other ions, reflecting the effect of imprinting.

[0035] Table 1 Selective adsorption test of lead ion imprinted polymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com