Method for preparing medium-density, high-strength and multi-purpose zirconium silicate composite micro-bead by using surplus materials

A zirconium silicate, multi-purpose technology, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve the problems of small application range of zirconium silicate beads, low density of finished microbeads, and difficulty in grinding out microbeads, etc., to achieve High cost performance, high production efficiency, good drainage and exhaust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

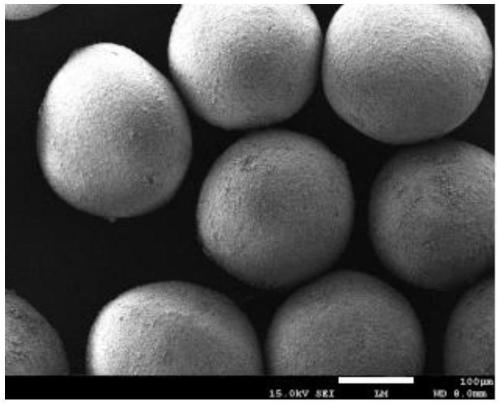

Image

Examples

Embodiment 1

[0041] (1) Ingredients: Prepare the raw materials in proportion, and the mass percentage in the formula is: 60% of the remaining zirconium silicate powder with D50 less than 7 μm, 37% of the remaining material of aluminum oxide powder with D50 less than 7 μm, and 3% of lignin; Among them, the remaining zirconium silicate powder with D50 less than 7 μm is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively. The remainder of alumina micropowder is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively.

[0042] (2) Dry blending: Mix the raw materials prepared in (1) in a three-dimensional mixer for 1.2 hours to fully mix the raw materials evenly.

[0043] (3) Moist mixing: add the mixture mixed in (2) to 7% by mass deionized water, and then carry out wet mixing in a planetary wet mill.

[0044] (4)...

Embodiment 2

[0059] (1) Ingredients: Prepare the raw materials in proportion, and the mass percentage in the formula is: 70% of the remaining material of zirconium silicate micropowder with D50 less than 7 μm, 27% of the remaining material of aluminum oxide micropowder with D50 less than 7 μm, and 3% of lignin; Among them, the remaining zirconium silicate powder with D50 less than 7 μm is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively. The remainder of alumina micropowder is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively.

[0060] (2) Dry blending: Mix the raw materials prepared in (1) in a three-dimensional mixer for 1.5 hours to fully mix the raw materials evenly.

[0061] (3) Moist mixing: Add the mixture mixed in (2) to 7% by mass deionized water, and then carry out wet mixing in a planetary w...

Embodiment 3

[0077] (1) Ingredients: Prepare the raw materials in proportion, and the mass percentage in the formula is: 81% of zirconium silicate micropowder with D50 less than 7 μm, 16% of aluminum oxide micropowder with D50 less than 7 μm, and 3% of lignin; Among them, the remaining zirconium silicate powder with D50 less than 7 μm is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively. The remainder of alumina micropowder is composed of powders with particle sizes less than 2.0 μm, 2.0-5.0 μm, and 5.0-7.0 μm, and the mass percentages are 3%, 80%, and 17% respectively.

[0078] (2) Dry mixing: Mix the raw materials prepared in (1) in a three-dimensional mixer for 1.6 hours to fully mix the raw materials evenly.

[0079] (3) Moist mixing: Add the mixture mixed in (2) to 7% by mass deionized water, and then carry out wet mixing in a planetary wet mill.

[0080] (4) Trapped material: Remove the ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com