Purification treatment method of raw hide pre-soaking liquid waste

A purification treatment and presoaking technology, which is applied in water/sewage treatment, chemical instruments and methods, heating water/sewage treatment, etc., can solve problems such as sodium chloride pollution, achieve less impurity content, occupy a small area, reduce Effect of Chloride Content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

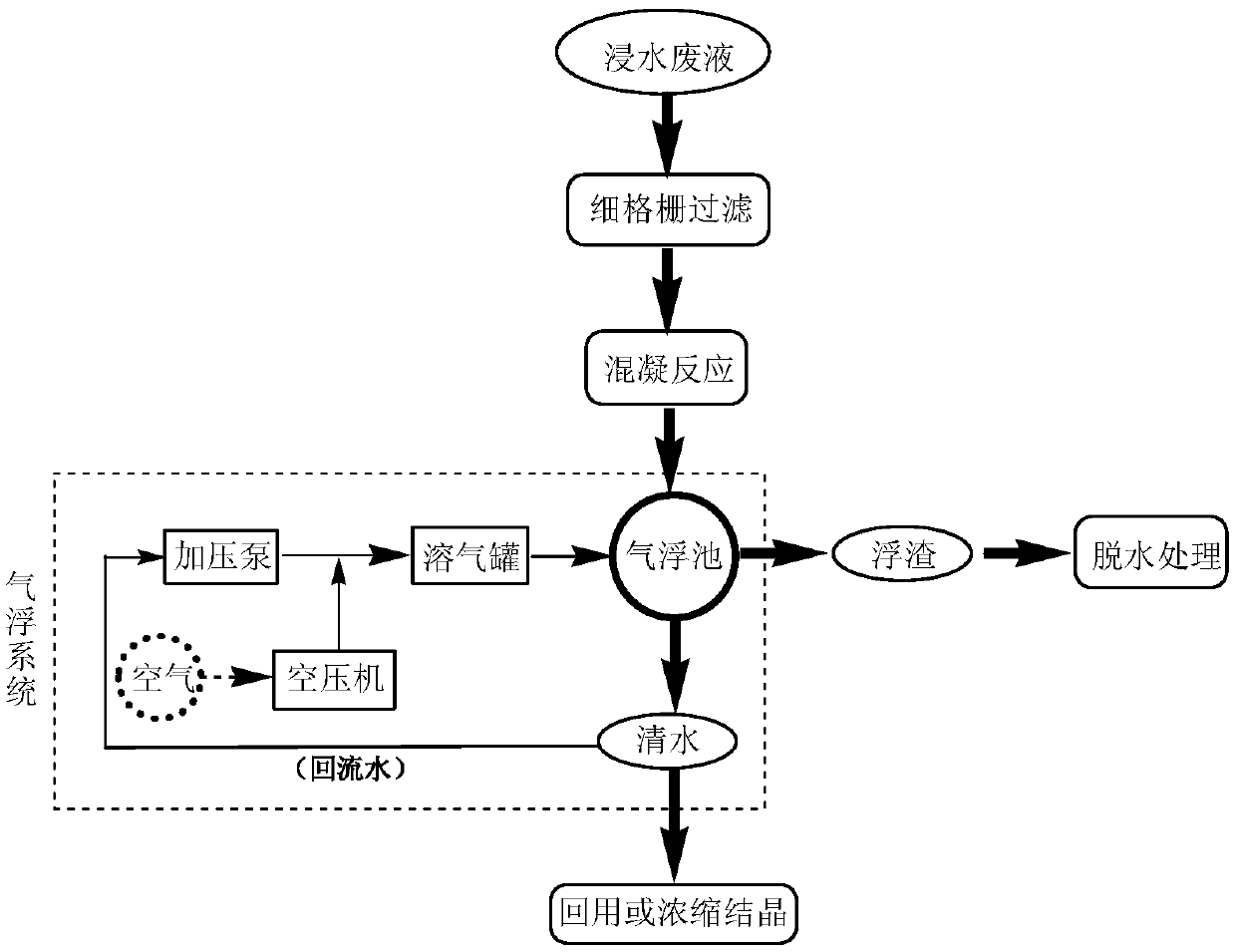

[0029] refer to figure 1 Purification treatment of raw hide pre-soaking water wastewater in cowhide tannery:

[0030] Step S1. Filtration of immersion waste liquid: filter the immersion waste liquid discharged from the drum by using a rotary mechanical grid with a rake tooth gap of 1 mm, and then collect the waste liquid in the coagulation tank;

[0031] Step S2. Coagulation reaction: Add the pre-dissolved polyaluminum chloride (PAC), nonionic polyacrylamide (PAM) and cationic polyacrylamide (CPAM) into the coagulation tank successively to make the mixture The concentrations of PAC, PAM, and CPAM in the coagulation tank are 50-80mg / L, 4-6mg / L, and 2-4mg / L respectively; then fully mixed and reacted for 15 minutes at a stirring speed of 150-200rpm to make the impurities in the waste liquid Form floc particles and suspend them in water to obtain wastewater treated by coagulation reaction;

[0032] Step S3. Air flotation treatment: Use an air compressor to pressurize, and use th...

Embodiment 2

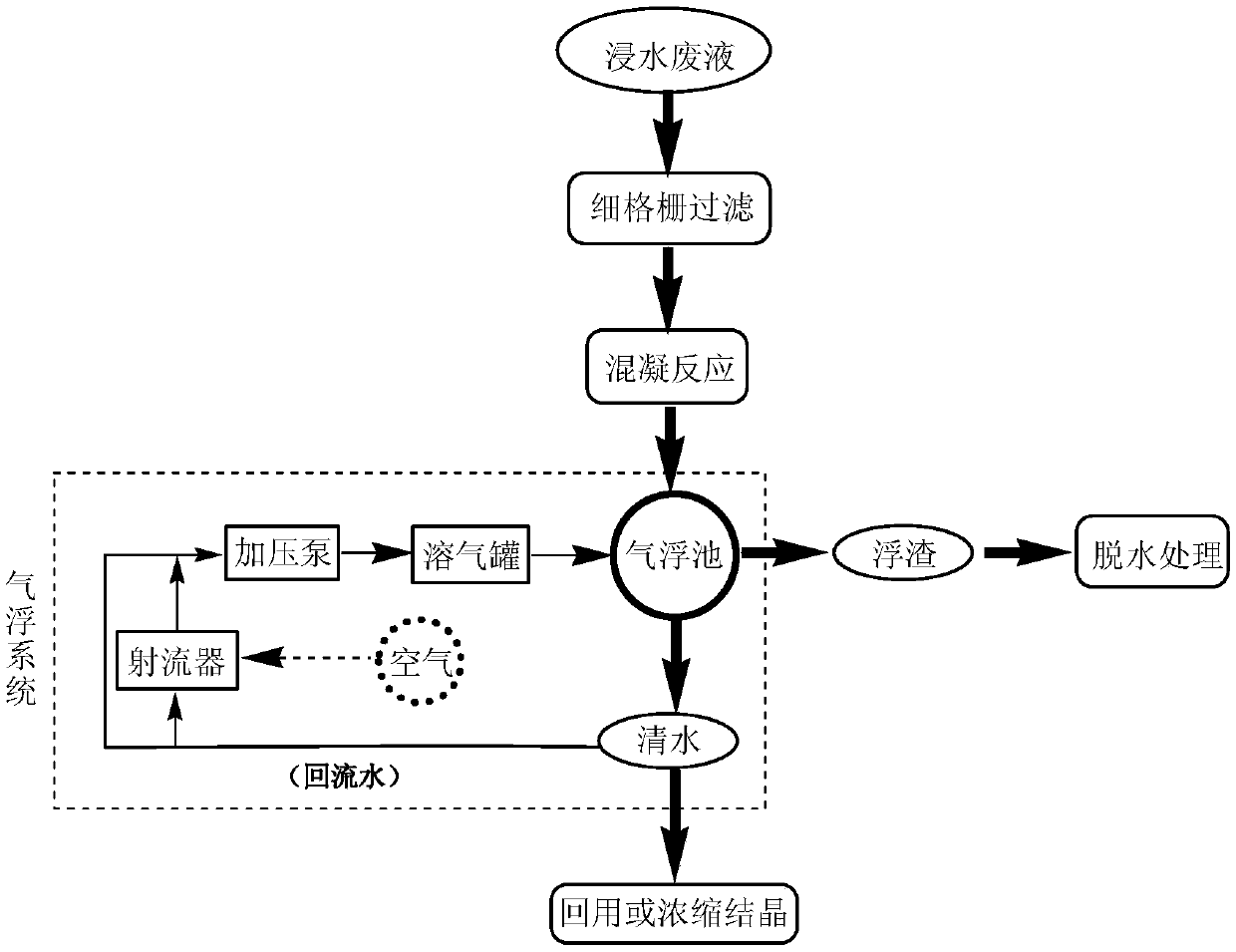

[0036] refer to figure 2 Purification of raw hide pre-soaking wastewater from goat leather tannery:

[0037] Step S1. Filtration of immersion waste liquid: filter the discharged immersion waste liquid with a rotary mechanical grid with a rake tooth grid gap of 2 mm, and then collect the waste liquid in a coagulation tank;

[0038] Step S2. Coagulation reaction: Add the pre-dissolved polyaluminum chloride (PAC), nonionic polyacrylamide (PAM) and cationic polyacrylamide (CPAM) into the coagulation tank successively to make the mixture The concentrations of PAC, PAM, and CPAM in the coagulation tank are 70-90mg / L, 4-6mg / L, and 3-5mg / L respectively; then fully mixed and reacted for 10 minutes at a stirring speed of 150-200rpm to make the impurities in the waste liquid Form floc particles and suspend them in water to obtain wastewater treated by coagulation reaction;

[0039] Step S3. Air flotation treatment: use water ejector to pressurize, adopt the pre-pump pressurization metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com