Preparation method of mannitol modified zero-valent iron NZVIM and application thereof

A mannitol, zero-valent iron technology, applied in chemical instruments and methods, special treatment targets, water/sludge/sewage treatment, etc., can solve the problems of particle agglomeration and blockage, inhibition of reactivity, easy passivation, and aggregation. , to achieve the effect of improving reaction activity, improving stability, and facilitating precipitation separation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

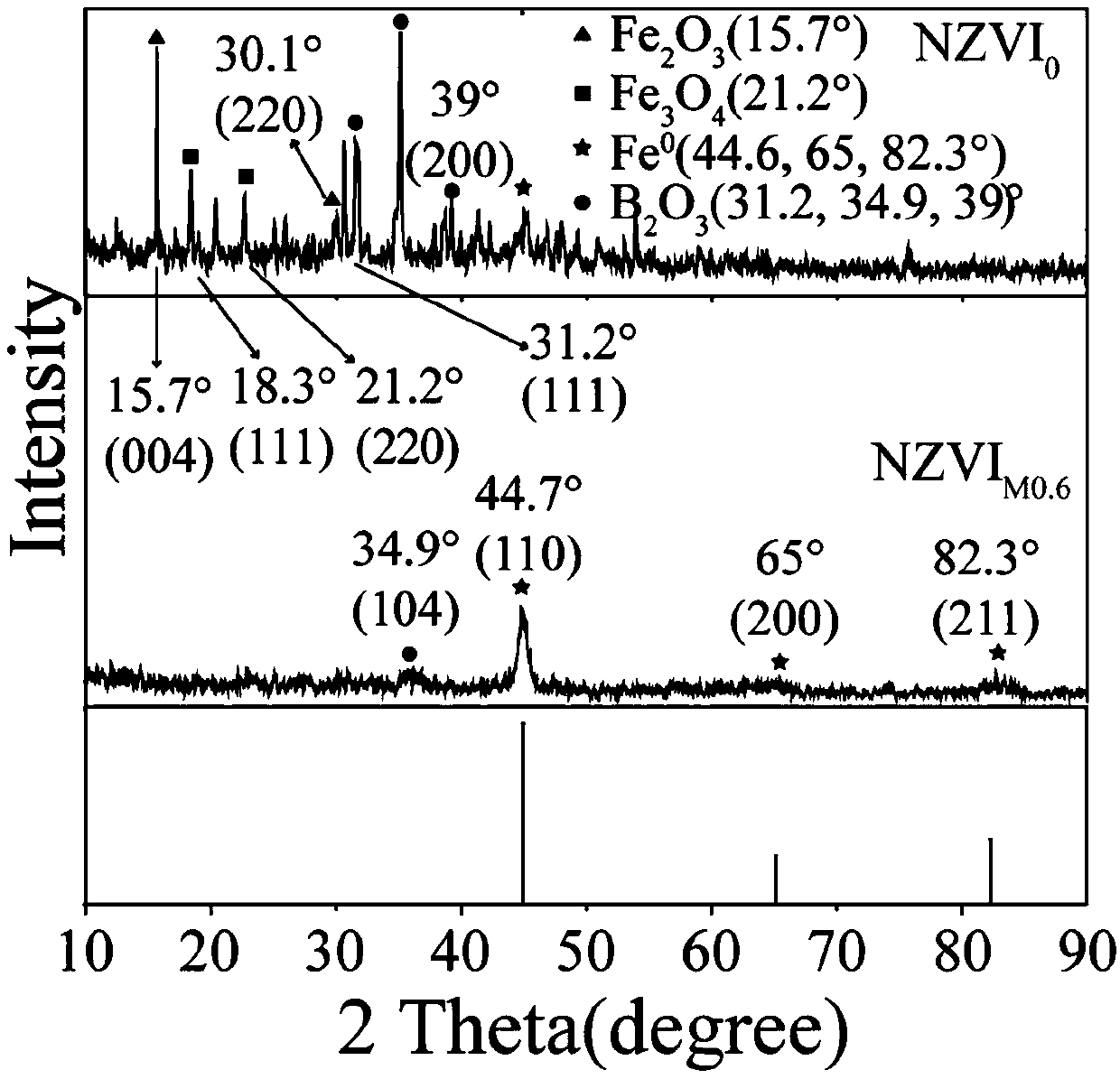

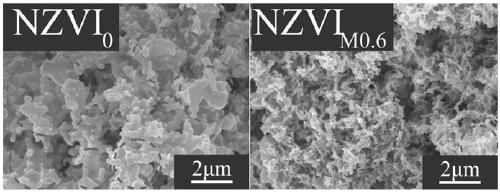

Embodiment 1

[0026] Weigh 4.84g FeCl 3 ·6H 2 O powder (17.91 mmol Fe 3+ ) was dissolved in 50mL deionized water, and then the solution was transferred to a three-necked bottle, which was recorded as solution A. Weigh 6.118g of NaBH4 powder (161 mmol BH4-) and dissolve it in 100mL of water, and record it as liquid B. Take liquid B and add it dropwise to solution A at a rate of 15 drops / min, and continue to stir for 20 minutes after the addition is completed. 2 It was carried out under the atmosphere, then vacuum-filtered and washed several times with absolute ethanol to obtain a black solid which was vacuum-dried at 60° C. overnight, and then sealed and stored with nitrogen gas. You can get unmodified nano zero-valent iron NZVI 0 .

Embodiment 2

[0028] Weigh 4.84g FeCl 3 ·6H 2 O powder (17.91 mmol Fe 3+ ) was dissolved in 50 mL of 0.6 mol / L mannitol aqueous solution, which was designated as solution A. Weigh 6.118g NaBH 4 powder (161 mmol BH4 - ) was dissolved in 100mL of water and recorded as liquid B. in N 2Under the atmosphere, take liquid B and add it dropwise to solution A at a rate of 15 drops / min. After the dropwise addition, continue to stir and react for 30 minutes, then vacuum filter and wash with absolute ethanol several times to obtain a black solid and dry it in vacuum at 70°C. , overnight, and sealed after being filled with nitrogen. Mannitol-modified nano zero-valent iron NZVI can be obtained M0.6 .

Embodiment 3

[0030] Weigh 4.84g FeCl 3 ·6H 2 O powder (17.91 mmol Fe 3+ ) was dissolved in 50 mL of 1.0 mol / L mannitol aqueous solution, recorded as solution A. Weigh 6.118g NaBH 4 powder (161 mmol BH4 - ) was dissolved in 100mL of water and recorded as liquid B. in N 2 Under the atmosphere, take liquid B and add it dropwise to solution A at a rate of 15 drops / min. After the dropwise addition, continue to stir and react for 30 minutes, then vacuum filter and wash with absolute ethanol several times to obtain a black solid and dry it in vacuum at 70°C. , overnight, and sealed after being filled with nitrogen. Mannitol-modified nano zero-valent iron NZVI can be obtained M0.6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com