Composite catalyst for hydrodeoxygenation reaction and preparation method thereof

A technology of composite catalyst and deoxidation reaction, which is applied in the direction of chemical instruments and methods, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of metal particles easy to agglomerate, become larger, and break the ring, so as to avoid metal particle agglomeration and operation Simple, large surface area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

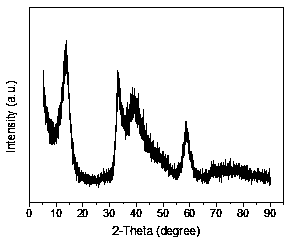

Image

Examples

Embodiment 1

[0022] Dissolve 0.1g of ammonium molybdate and 1.5g of thiourea in 100mL of water, and conduct a hydrothermal reaction at 200°C for 24h to prepare MoS 2-x . In a stoppered Erlenmeyer flask, 0.3 g MoS 2-x The powder was dispersed in 50 mL of water, and after ultrasonic vibration for 1 h, chloroplatinic acid was added according to the mass content of 2.5% Pt in the composite catalyst. °C and vacuum-dried for 6 hours to obtain a black catalyst.

[0023] Add 12.5 g of n-dodecane, 2.4 g of p-cresol, a typical oxygen-containing compound in biomass oil, and 0.05 g of the above-mentioned catalyst in the autoclave, install the device, use the replacement method to get rid of the air in the autoclave, and then use 10 The rate of ℃ / min was raised from room temperature to 160 ℃, the rotation speed was adjusted to 900 r / min, and the hydrogen pressure was 5.0 MPa. After 3 h of reaction, the conversion rate of p-cresol reached 100%, and the selectivity of methylcyclohexane The hydrodeoxy...

Embodiment 2

[0025] The catalyst was prepared according to the method in Example 1, only the standing temperature and time were changed to 20°C and 24h, and other conditions remained unchanged.

[0026] Add 12.5 g of n-dodecane, 2.4 g of p-cresol, a typical oxygen-containing compound in biomass oil, and 0.05 g of the above-mentioned catalyst in the autoclave, install the device, use the replacement method to get rid of the air in the autoclave, and then use 10 The rate of ℃ / min was raised from room temperature to 140 ℃, the rotation speed was adjusted to 900 r / min, and the hydrogen pressure was 5.0 MPa. After 4 h of reaction, the conversion rate of p-cresol reached 100%, and the selectivity of methylcyclohexane The hydrodeoxygenation activity of the catalyst remained basically unchanged after 5 cycles of reaction.

Embodiment 3

[0028] The catalyst was prepared according to the method in Example 1, except that the mass content of Pt in the composite catalyst was changed to 5%, and the standing temperature and time were changed to 60°C and 12h.

[0029] Add 12.5 g of n-dodecane, 2.4 g of p-cresol, a typical oxygen-containing compound in biomass oil, and 0.05 g of the above-mentioned catalyst in the autoclave, install the device, use the replacement method to get rid of the air in the autoclave, and then use 10 The rate of ℃ / min was increased from room temperature to 140 ℃, the rotation speed was adjusted to 900 r / min, and the hydrogen pressure was 5.0 MPa. After 2 hours of reaction, the conversion rate of p-cresol reached 97.7%, and the selectivity of methylcyclohexane was 94.5%, after 5 cycles of reaction, the hydrodeoxygenation activity of the catalyst remained basically unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com