Operation method of recycling process system for treating VOCs (volatile organic compounds) waste gas

A technology of process system and operation method, which is applied in the field of VOCs exhaust gas recycling process system operation, can solve problems such as leakage, VOCs exhaust gas seal failure, and no solution for the electric heating purification filter element, so as to achieve the effect of reducing pollutant emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

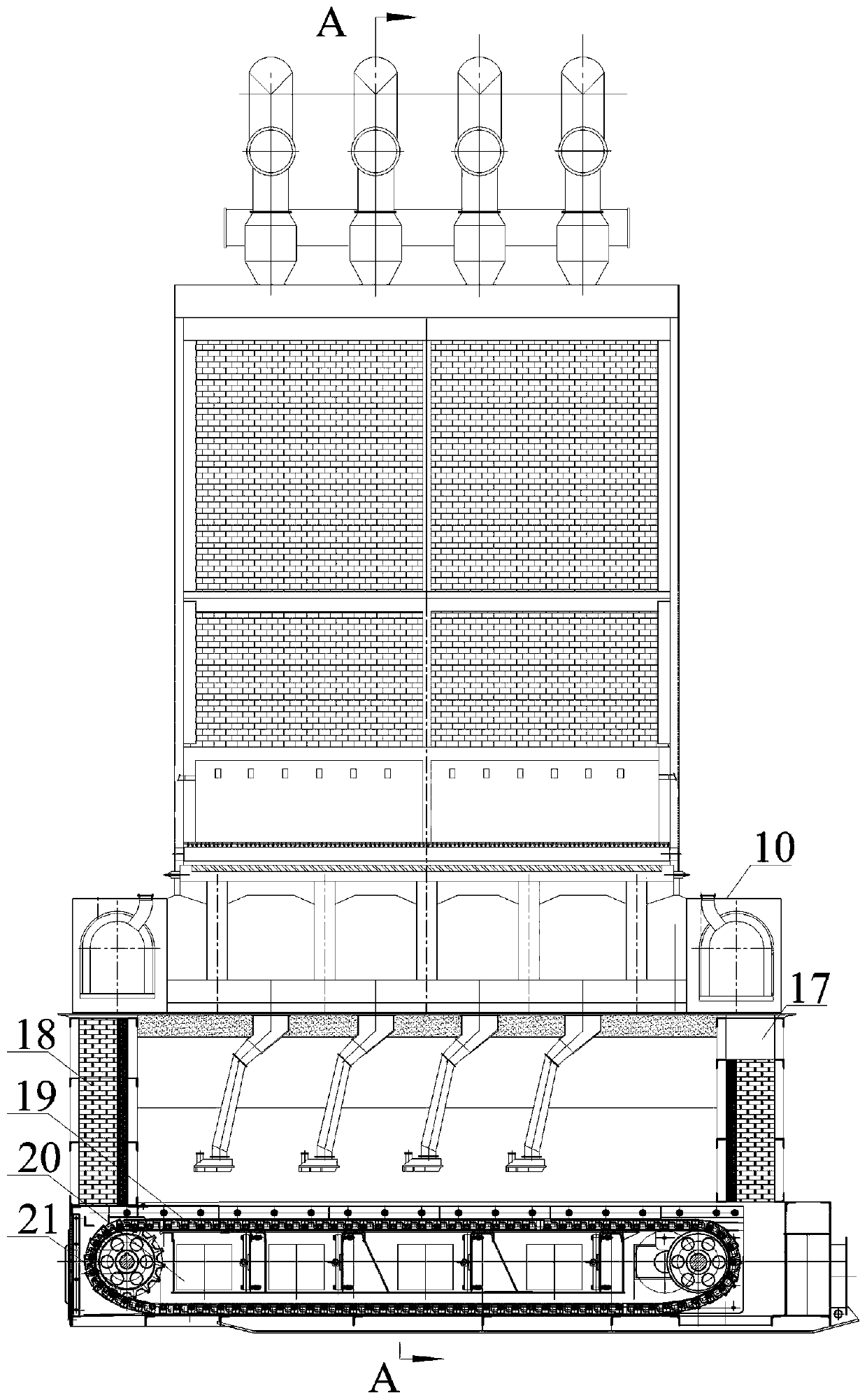

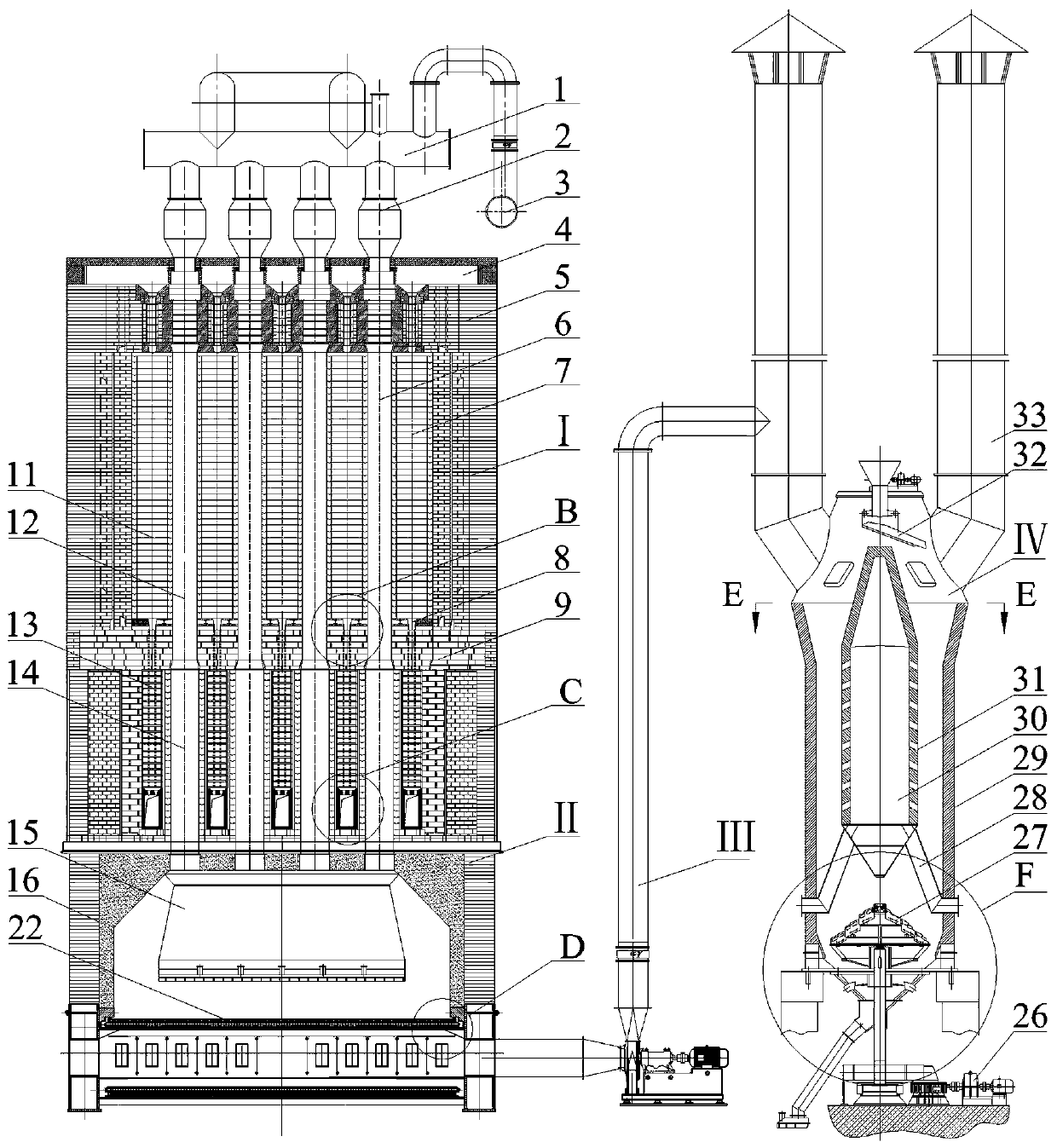

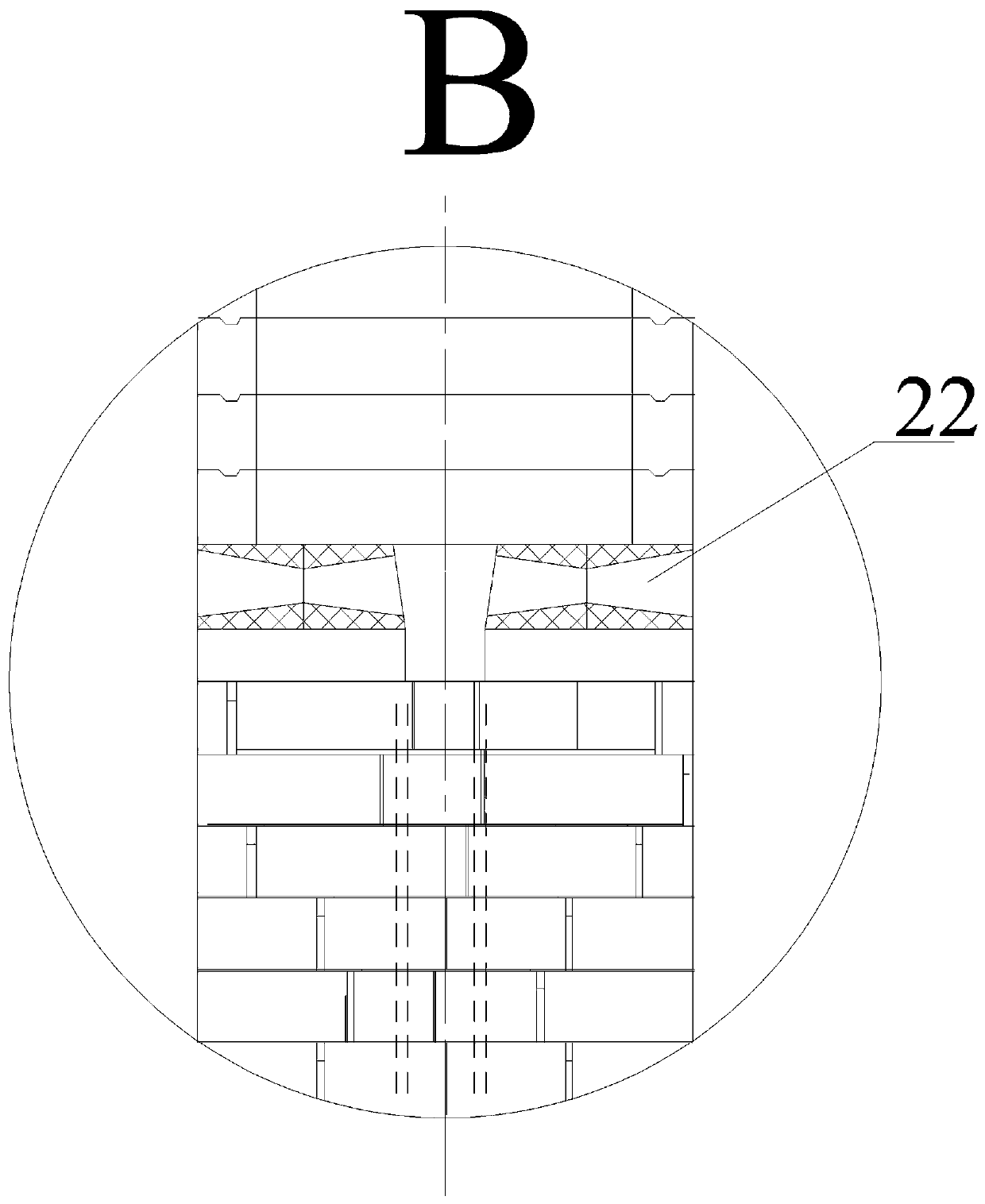

[0038] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 Shown, a kind of treatment VOCs exhaust gas cycle regeneration process system operation method is characterized in that:

[0039]Step 1. Before operation, the static test run debugging of desorption pyrolysis furnace Ⅰ and chain drive grate bed Ⅱ and joint debugging and joint test of induced draft system Ⅲ and adsorbent moving bed Ⅳ should be carried out. The flue 7 is filled with high-alumina ball packing, and the particle diameter of the high-alumina ball packing is 20-25 mm. The adsorbent to be desorbed is delivered to the vertical channel 6 in the desorption pyrolysis furnace body 5 through the feeding system 1, and the vertical channel 6 is And the material leg 15 is filled with adsorbent particles, cut off the flue collecting duct 10 to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com