Capsicol and preparation technology thereof

A preparation process, technology of chili oil, applied in the direction of edible oil/fat, food science, application, etc., can solve problems such as easy to get angry, and chili oil is prone to dryness, etc., to improve clear fire and reduce dryness, rich taste, eliminate The effect of dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

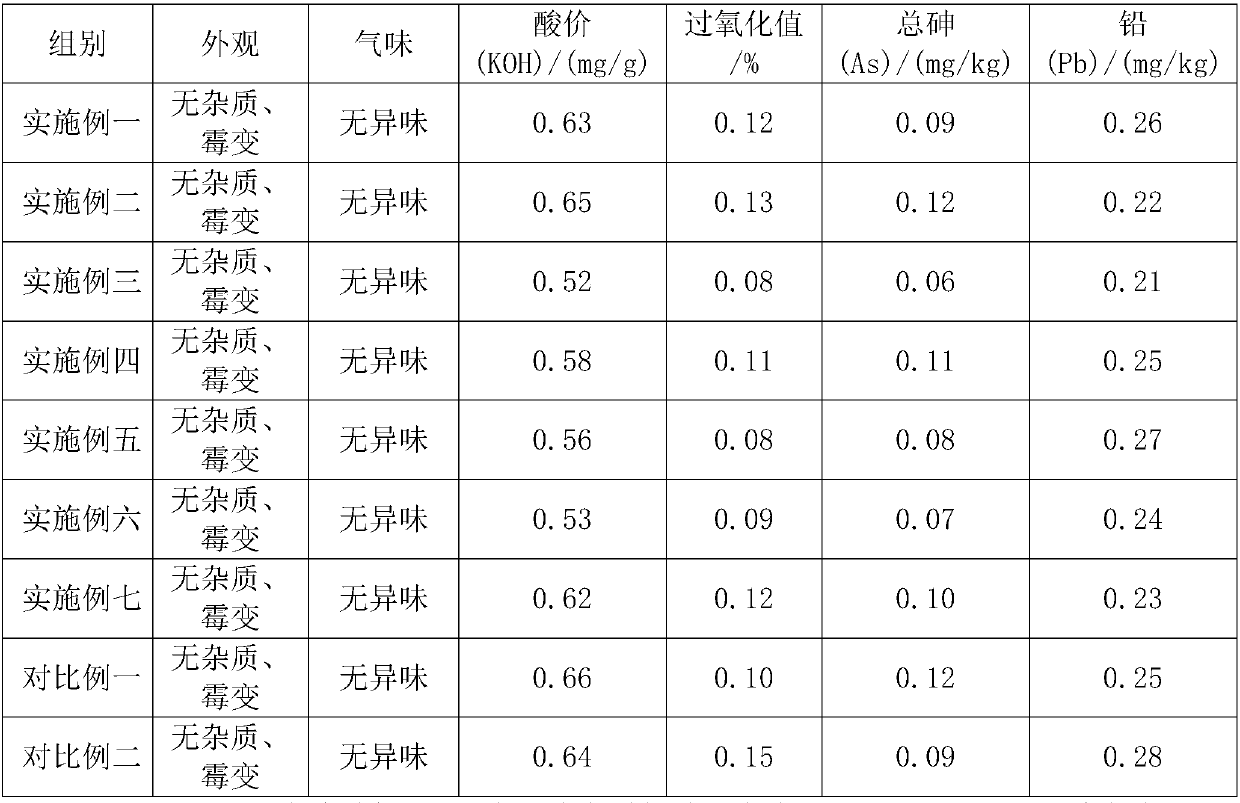

Examples

Embodiment 1

[0031] The present embodiment provides a kind of preparation technology of capsicum oil, comprises the following steps:

[0032] Step 1: Prepare chili powder: remove 10kg of dried chili peppers, grind them into powder, and set aside. The dried chili peppers here are complete dried chili peppers without mildew, insect damage, and impurities. The dried chili peppers used in this example are Chaotian pepper.

[0033] Step 2: Prepare hot oil: Heat 75kg of vegetable oil in an oil pan, add 1.5kg of Zanthoxylum bungeanum and 1kg of ginger after the oil foam is gone, fry the Zanthoxylum bungeanum and ginger until they turn yellow, then remove. The vegetable oil here is edible oil extracted from plants, for example, soybean oil, peanut oil, rapeseed oil, corn oil or sunflower oil. The vegetable used in this embodiment is soybean oil. When the oil temperature drops to 90° C., add 0.25 kg of star anise, 0.1 kg of bamboo leaves and 0.15 kg of citronella, and keep stirring to obtain hot o...

Embodiment 2

[0037] The difference between this example and Example 1 is mainly that in the step 3 of preparing chili oil in this example, flavoring auxiliary materials are also added, and 0.25 kg of chili powder is added to the hot oil whose temperature drops to 75°C. Sesame powder and 0.25kg of coix seed powder were stirred evenly to obtain a semi-finished product, and the subsequent step 4 was also the same as in Example 1.

Embodiment 3

[0039] The difference between the present embodiment and the first embodiment mainly lies in that the preparation process of the chili oil of the present embodiment comprises the following steps:

[0040] Step 1: Prepare chili powder: remove 10kg of dried chili peppers and grind them into powder for later use. The dried chili peppers used in this example are millet peppers.

[0041] Step 2: Prepare hot oil: heat 68kg of vegetable oil in an oil pan, add 1.6kg of Zanthoxylum bungeanum and 1kg of ginger after the oil foam is gone, and fry the Zanthoxylum bungeanum and ginger until they turn yellow. Vegetables for peanut oil. When the oil temperature was down to 100° C., add 0.32 kg of star anise, 0.16 kg of bamboo leaves and 0.24 kg of citronella, and keep stirring to obtain hot oil.

[0042]Step 3: Prepare semi-finished products: Add the chili powder prepared in Step 1 into hot oil with an oil temperature of 90°C, and stir at the same time. When the oil temperature drops to 85°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com