Quantitative testing device for long-term chemical stability of industrial nitrocellulose

A technology of nitrocellulose and chemical stability, which is applied in the direction of material analysis by observing the influence of chemical indicators, and analysis by making materials undergo chemical reactions, which can solve the problem that the amount of nitrous gas cannot be quantitatively measured and can only be qualitatively tested. and other issues to achieve reliable conclusions and good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

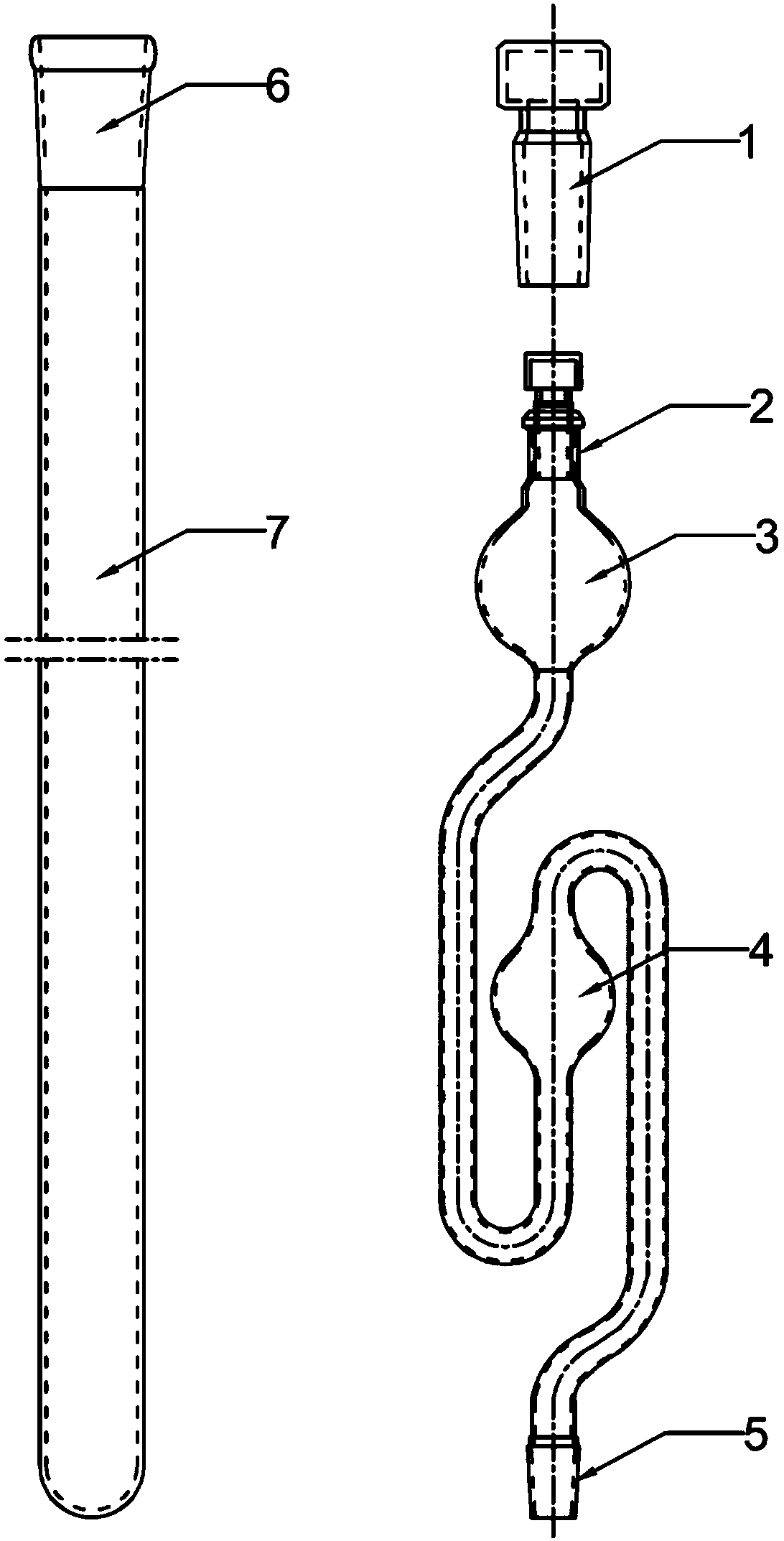

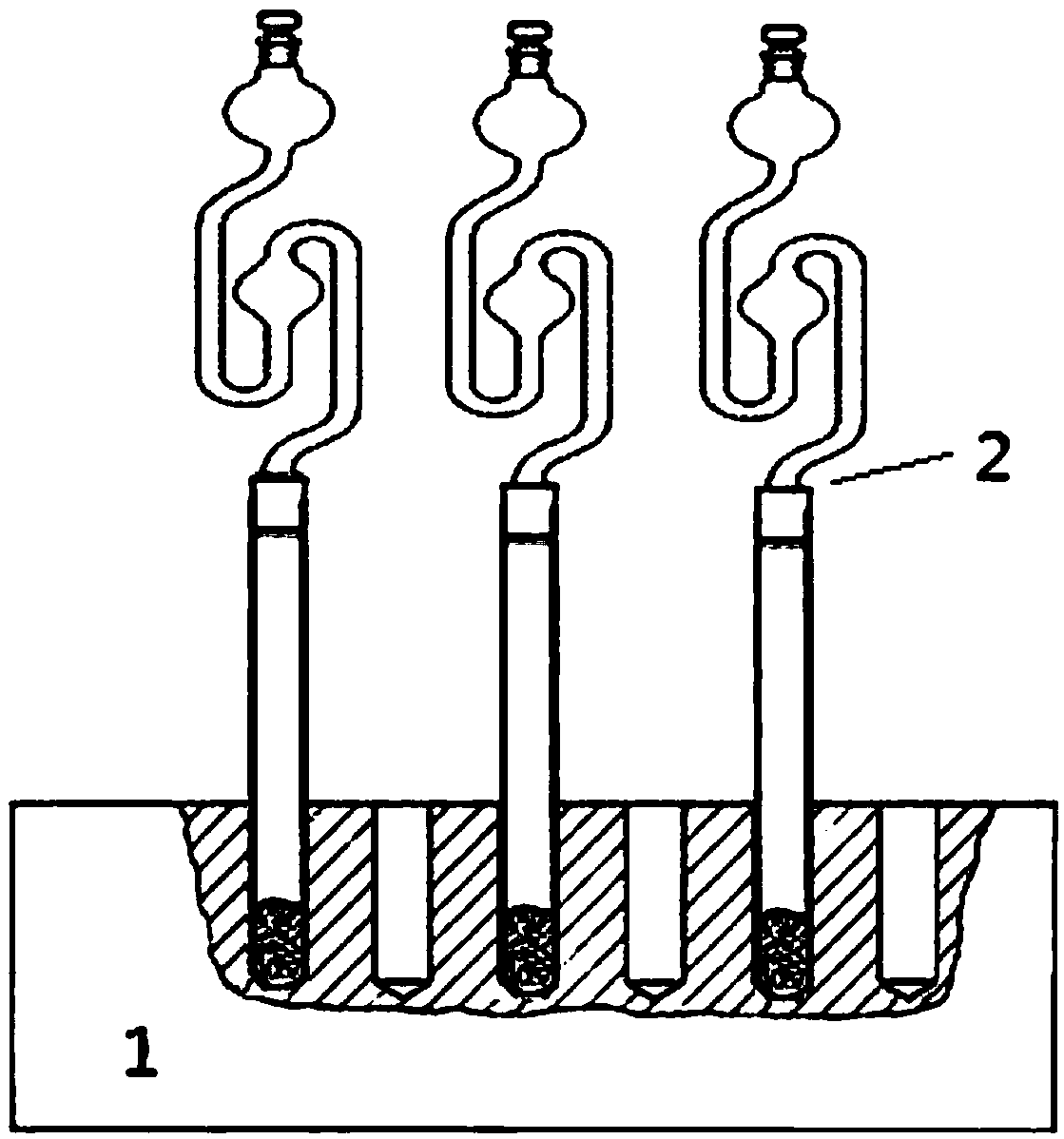

[0034] A quantitative test device for long-term chemical stability of industrial nitrocellulose, nitrocellulose stability test tube such as figure 1 as shown, figure 1 In the middle, the left side is the glass tube in the lower part of the test tube, and the right side is the condenser in the upper part of the test tube. During the experiment, the nitrocellulose sample was added to the glass tube on the left, and the condenser was connected to the upper part. In the figure, the ground plug 1 is connected to the ground port 2, and the ground plug 5 is connected to the ground port 6 to complete the assembly of the stability test tube.

[0035] The invention is applicable to the quantitative stability test of various types of nitrocellulose.

[0036] 1. Test principle:

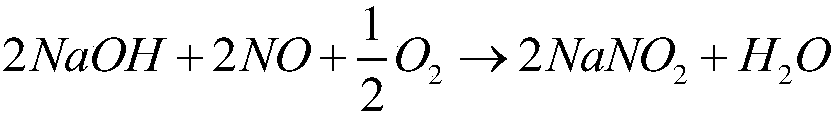

[0037] Put 1 or 2g of nitrocellulose sample into a stable tube, heat it in a constant temperature metal bath at 132°C±1°C for two hours, and measure the amount of nitrous gas released during the heating proces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com