Pressure sensitive thin film, sensor, sensor array and corresponding preparation methods of pressure sensitive thin film, sensor and sensor array

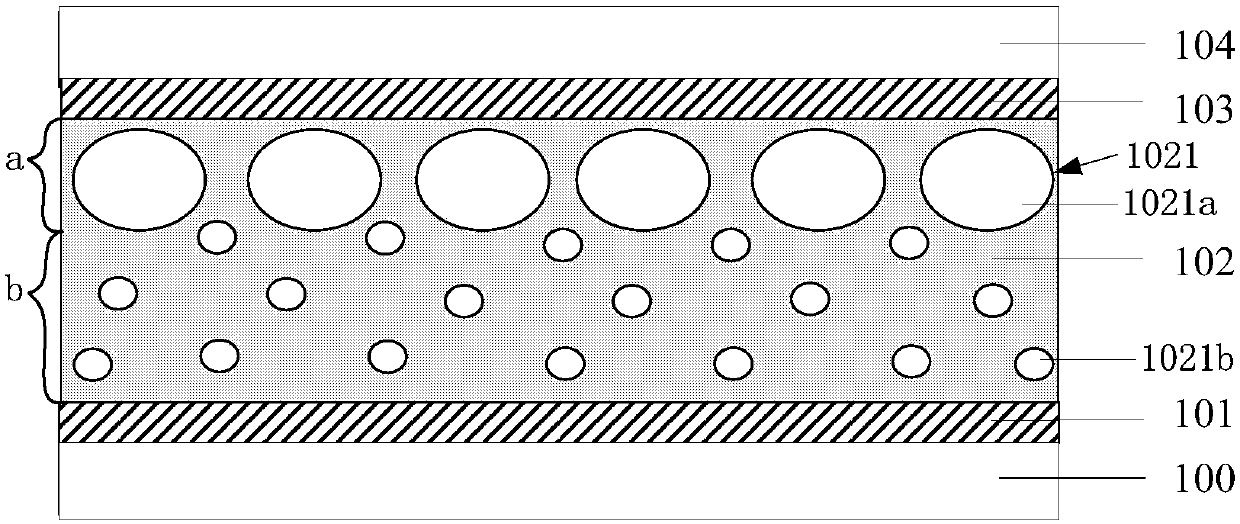

A pressure sensor and sensitive film technology, applied in the field of pressure sensitive films, sensor arrays and their respective preparations, and pressure sensors, can solve the problems of easy deformation of microstructures and increase costs, reduce deformation recovery time, eliminate process steps, reduce The effect of process complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

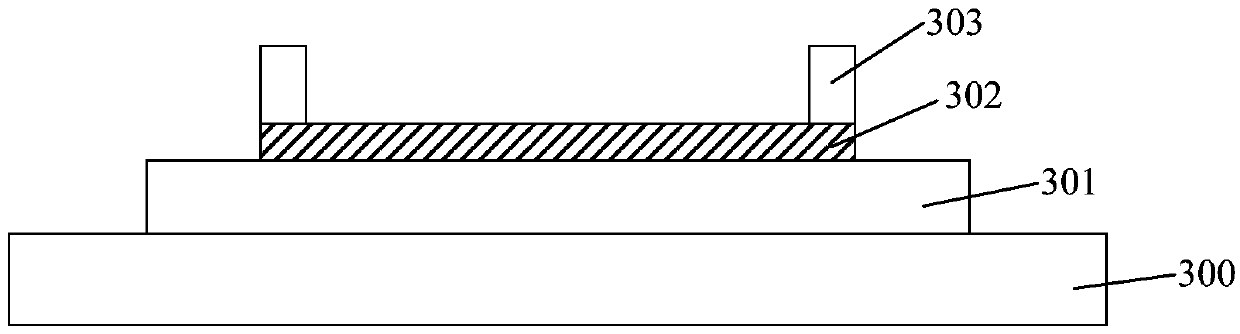

[0065] A specific embodiment of the present invention also provides a method for preparing the above-mentioned pressure sensor array, including:

[0066] A first base plate and a second base plate are provided, the first base plate has a first substrate, the surface of the first substrate is formed with a plurality of upper electrode lines arranged in parallel, and the second base plate has a second substrate , the surface of the second substrate is formed with a plurality of lower electrode lines arranged in parallel. The upper electrode lines are of the same size and spacing, and the lower electrode lines are of the same size and spacing.

[0067] Support bars are formed on the outer edges of the upper electrode line and the lower electrode line at the edge of the sensor array area, and support bars are formed on both sides of the opposite width of the other electrode line. The support bar is located at the edge of the array area, which is convenient for subsequent removal ...

Embodiment 1

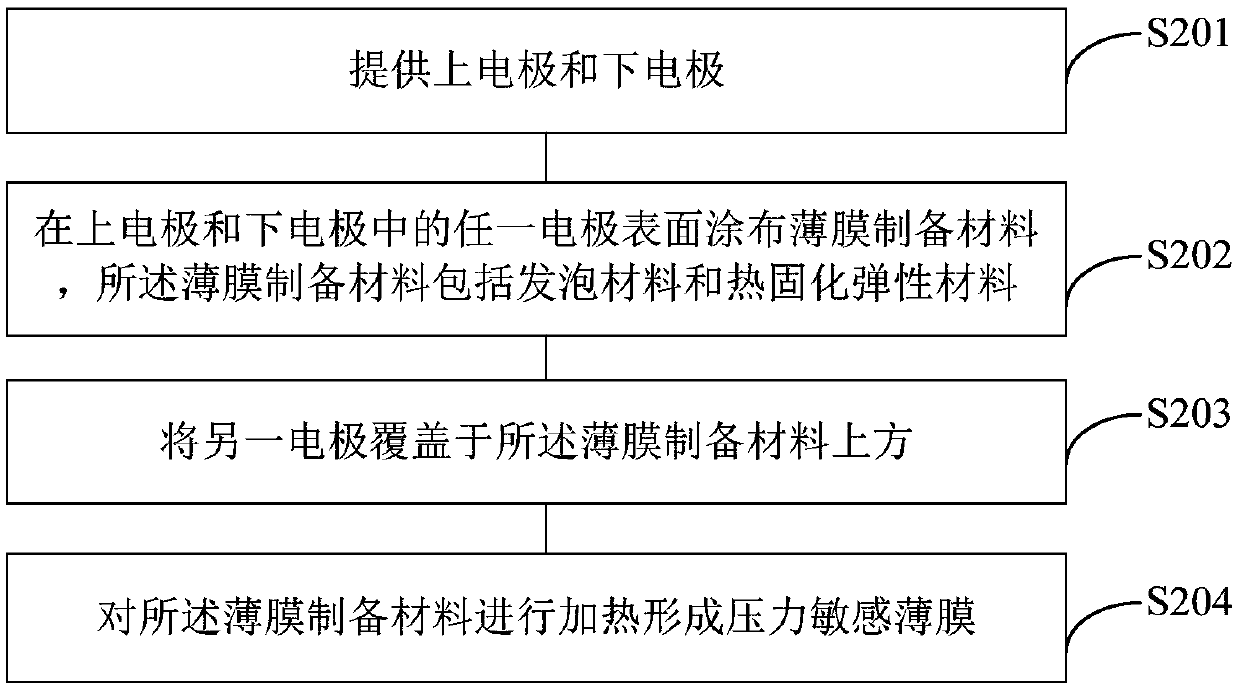

[0072] The pressure sensor is completed through the following specific steps:

[0073] (1) Utilize ethanol solution, acetone solution and deionized water ethylene terephthalate (PET) substrate to carry out ultrasonic cleaning, dry after cleaning, adopt oxygen plasma or ultraviolet light / ozone to process substrate surface; (2 ) preparing an aluminum electrode on the substrate by vacuum evaporation;

[0074] (3) Prepare two bottom plates with the same size and flat surface, attach the substrates of the prepared electrodes to the surface of the bottom plate respectively, and paste glass support strips with a height of 1.1 mm on both sides of the electrodes;

[0075] (4) Weigh the prepolymer of polydimethylsiloxane, weigh the foaming material according to the prepolymer mass ratio of polydimethylsiloxane to 10:2 and mix evenly, The prepolymer mass ratio of polysiloxane is 10:1, and the dimethylsiloxane curing agent is weighed and mixed uniformly;

[0076] (5) Pour the mixed mate...

Embodiment 2

[0081] The pressure sensor is completed through the following specific steps:

[0082] (1) Utilize ethanol solution, acetone solution and deionized water ethylene terephthalate (PET) substrate to carry out ultrasonic cleaning, dry after cleaning, adopt oxygen plasma or ultraviolet light / ozone to process substrate surface; (2 ) preparing an indium tin oxide electrode on the substrate by magnetron sputtering;

[0083] (3) Prepare two bottom plates with the same size and flat surface, attach the substrates of the prepared electrodes to the surface of the bottom plate respectively, and paste glass support strips with a height of 1.1 mm on both sides of the electrodes;

[0084] (4) Weigh the polydimethylsiloxane prepolymer, weigh the foaming material according to the mass ratio of the polydimethylsiloxane prepolymer to 10:2 and mix evenly, press the polydimethylsiloxane prepolymer The mass ratio of siloxane prepolymer is 10:1 to take by weighing dimethyl siloxane curing agent and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com