A high-strength screw

A high-strength, screw technology, applied in the direction of screws, threaded fasteners, mechanical equipment, etc., can solve the problems of unenhanced screw strength, screw damage, waste of raw materials, etc., and achieve the effect of solving screw breakage and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

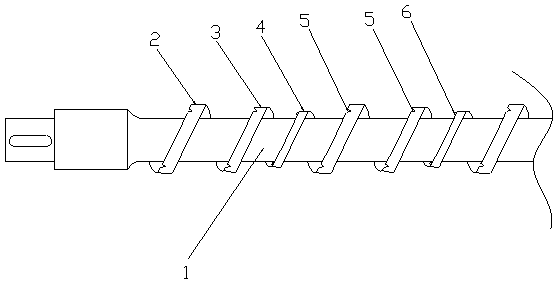

[0024] Please refer to figure 1 , a high-strength screw, including a screw body 1, the surface of the screw body 1 is provided with threads, and the threads include high threads 2, medium threads 3 and low threads 4, and medium threads are sequentially arranged between two sections of high threads 2 3 and low thread 4, high thread 2 and medium thread 3 are provided with notch 5, and low thread 4 is provided with projection 6, and the height of described projection 6 is less than the height difference between medium thread 2 and low thread 4 , wherein the ratio of the pitch between the high thread 2 and the medium thread 3 to the pitch between the medium thread 3 and the low thread 4 is 1:1~3.

[0025] The above-mentioned high-strength screw is made of high-strength materials, and the high-strength materials include: Fe: 85 parts by mass, Cr: 3 parts by mass, Ni: 5 parts by mass, Mo: 2.5 parts by mass, C: 1.5 parts by mass, Al: 2 Parts by mass, Mn: 1.5 parts by mass, Si: 1.4 p...

Embodiment 2

[0033] Example 2 is different from Example 1 in that Fe: 80 parts by mass, Cr: 2 parts by mass, Ni: 2 parts by mass, Mo: 2 parts by mass, C: 1 part by mass, Al: 1 part by mass, Mn: 1 part by mass, Si: 1.2 parts by mass, Cu: 1 part by mass, Ti: 1 part by mass; the weight ratio of modified carbon nanotubes to pure aluminum powder is 1:5, and the vacuum degree of the vacuum stirring ball mill is 10 -3 Pa, the rotation speed is 500rpm, the mixing time of the ball mill is 30min, the ball material ratio is 10:1; the vacuum degree used in the vacuum melting furnace is 10 -3 Pa, the stirring speed is 100rpm, and the stirring time is 30min.

Embodiment 3

[0035] Embodiment 3 differs from Embodiment 1 in that it includes Fe: 90 parts by mass, Cr: 4 parts by mass, Ni: 6 parts by mass, Mo: 3 parts by mass, C: 2 parts by mass, Al: 3 parts by mass, Mn : 2 parts by mass, Si: 1.5 parts by mass, Cu: 1.5 parts by mass, Ti: 1.4 parts by mass, the weight ratio of modified carbon nanotubes to pure aluminum powder is 1:30, and the vacuum degree of the vacuum stirring ball mill is 10 -1 Pa, the rotation speed is 2000rpm, the mixing time of the ball mill is 6h, the ball material ratio is 50:1; the vacuum degree used in the vacuum melting furnace is 10 -1 Pa, the stirring speed is 1000rpm, and the stirring time is 1h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com