Purification method for medium-low grade bentonite

A purification method and technology of bentonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems such as increased cost and short cycle, and achieve the effects of convenient operation, simple steps and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

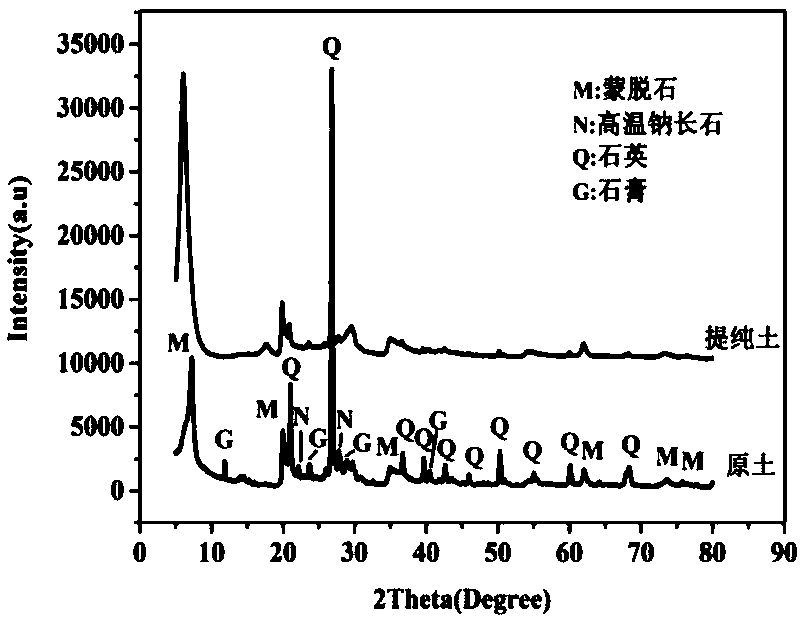

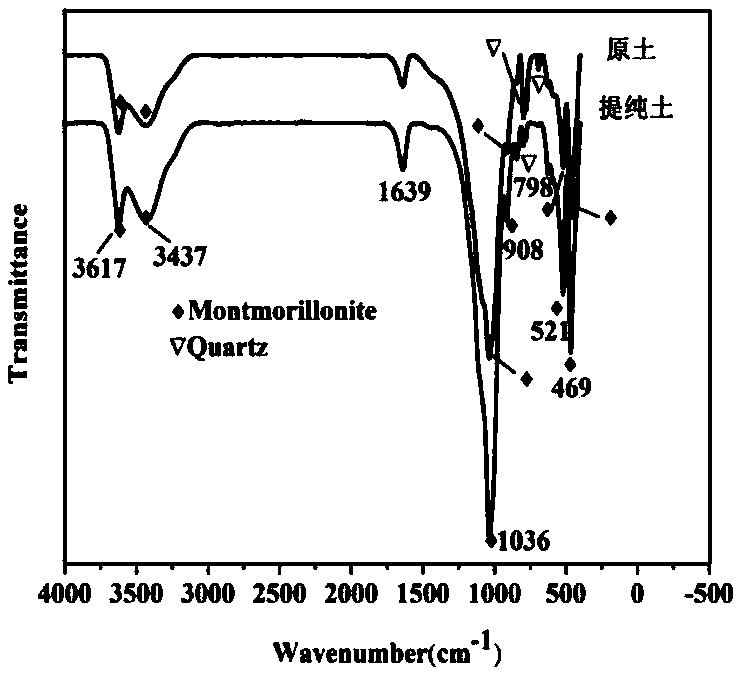

[0030] S1: Grind bentonite raw ore (montmorillonite content is 33%) and pass through a 200-mesh sieve to obtain bentonite powder with a particle size of 0.075 mm; mix bentonite powder and deionized water at a solid-to-liquid ratio of 1:12 to make bentonite slurry , stirred with an electric stirrer for 30 min, then stood still for 24 h, adjusted the system to 0.001 mol / L HCl system, stirred until there was no obvious foaming, and removed the carbonate in the raw ore;

[0031] S2: Let it stand until the supernatant is clear, then discard the supernatant; add water to the original scale, add 1 mLH 2 o 2 , placed in a constant temperature oscillator, and shaken at a constant temperature at 40 °C for 1 h to make it fully react and remove the organic matter in the components; let the bentonite slurry stand for 8 h to settle naturally, and extract more than 10 cm by siphon method Suspension, repeated addition of deionized water and extraction;

[0032] S3: Centrifuge the extracted ...

Embodiment 2

[0035] S1: Grind bentonite raw ore (57% montmorillonite content) and pass through a 200-mesh sieve to obtain bentonite powder with a particle size of 0.075 mm; mix bentonite powder and deionized water at a solid-to-liquid ratio of 1:12 to make bentonite slurry , stirred with an electric stirrer for 30 min, then stood still for 24 h, adjusted the system to 0.001 mol / L HCl system, stirred until there was no obvious foaming, and stood until the supernatant was clear, then poured off the supernatant;

[0036] S2: Refill water to the original scale, add 1 mLH 2 o 2 , placed in a constant temperature shaker, and shaken at a constant temperature at 40 °C for 1 h to make it fully react and remove the reducing groups in the components. After the bentonite slurry was allowed to settle naturally for 8 hours, the suspension above 10 cm was extracted by siphon method, and deionized water was added and extracted repeatedly;

[0037] S3: centrifuge the extracted upper layer suspension to r...

Embodiment 3

[0040] S1: Grind bentonite raw ore (57% montmorillonite content) and pass through a 200-mesh sieve to obtain bentonite powder with a particle size of 0.075 mm; mix bentonite powder and deionized water at a solid-to-liquid ratio of 1:8 to make bentonite slurry , stirred with an electric stirrer for 30 minutes, then stood still for 24 hours, adjusted the system to 0.001 mol / L HCl system, stirred to make the reaction without obvious foaming, stood until the supernatant was clear, and poured off the supernatant;

[0041] S2: Refill water to the original scale, add 1 mLH 2 o 2 , placed in a constant temperature shaker, and shaken at a constant temperature at 40 °C for 1 h to make it fully react and remove the reducing groups in the components. After the bentonite slurry was allowed to settle naturally for 8 hours, the suspension above 10 cm was extracted by siphon method, and deionized water was added and extracted repeatedly;

[0042] S3: centrifuge the extracted upper layer sus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com