Method for extracting plant anthocyanins

An anthocyanin and plant technology, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of uncoordinated solvent use process, difficult separation and purification, complicated preparation steps, etc., and achieve 100% atom utilization , Improve the extraction efficiency, the effect of cheap and easy-to-get raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

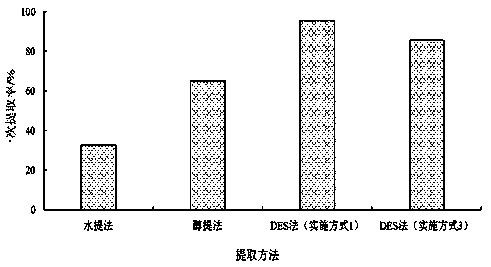

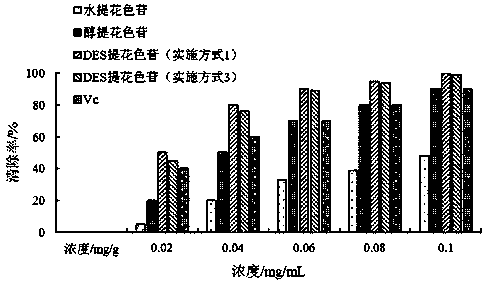

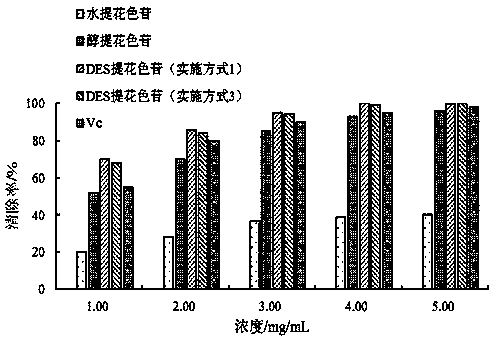

Embodiment approach 1

[0027] This embodiment provides a method for extracting anthocyanins from mulberries. Take fresh mulberry fruits, remove the stems, beat them into a homogenate with a mixer, take 10 g of the homogenate and use the deep eutectic solvent choline chloride-lactic acid (molar ratio 1: 3, water content 0%wt) as the extraction solvent, extract for 10 minutes under the conditions of solid-to-liquid ratio 1g: 30mL, ultrasonic power 100W, electrostatic field strength 4kV, extraction temperature 50°C to obtain anthocyanin extract; add the above anthocyanin extract Add 5g of attapulgite-loaded chitosan cross-linked cyclodextrin complex, shake it on a shaking table at 30°C and 100r / min for 4 hours, take the precipitate after centrifugation, wash it with deionized water ultrasonically for 3 times, and centrifuge to get the adsorbed on the attapulgite Anthocyanin precipitation on the soil-loaded chitosan cross-linked cyclodextrin complex; add 80% ethanol to the anthocyanin precipitation for u...

Embodiment approach 2

[0039] This embodiment provides a method for extracting anthocyanins from mulberries. Take fresh mulberry fruits, remove the stems, beat them into a homogenate with a mixer, take 10 g of the homogenate and use the deep eutectic solvent choline chloride-acetic acid (molar ratio 2: 3, the water content is 15%wt) as the extraction solvent, and the solid-to-liquid ratio is 1g: 10mL, the ultrasonic power is 300W, the electrostatic field strength is 5kV, and the extraction temperature is 50°C, and the anthocyanin extract is obtained for 20min; the above anthocyanin extract Add 3 g of attapulgite-loaded chitosan cross-linked cyclodextrin complex, shake it on a shaking table at 30°C and 100 r / min for 5 hours, centrifuge to get the precipitate, wash it with deionized water ultrasonically for 3 times, and centrifuge to get the adsorbed on the attapulgite Anthocyanin precipitation on the soil-loaded chitosan cross-linked cyclodextrin complex; add 60% ethanol to the anthocyanin precipitati...

Embodiment approach 3

[0042] This embodiment provides a method for extracting anthocyanins in mulberries. Take fresh mulberry fruits, remove the stems, beat them into a homogenate with a mixer, take 10 g of the homogenate and use the deep eutectic solvent choline chloride-lactic acid-acetic acid (molar ratio 1:2:1, water content 30%wt) as the extraction solvent, under the conditions of solid-liquid ratio 1g:20mL, ultrasonic power 400W, electrostatic field strength 9kV, extraction temperature 60°C for 30min to obtain anthocyanin extract; Add 2 g of attapulgite-loaded chitosan cross-linked cyclodextrin complex to the obtained anthocyanin extract, shake it on a shaking table at 30°C and 100 r / min for 5 hours, centrifuge to collect the precipitate, and wash it with deionized water ultrasonically for 3 times. Centrifuge to obtain the anthocyanin precipitate adsorbed on the attapulgite-loaded chitosan cross-linked cyclodextrin complex; add ethanol with a mass fraction of 70% to the anthocyanin precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com