Efficient 3D printing device based on characteristics of 3D printing material

A technology of 3D printing and material characteristics, applied in the field of 3D printing, can solve the problems of easy oxidation of printed products and underground products, and achieve the effects of fast printing speed, overall quality improvement, and accurate and rapid positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

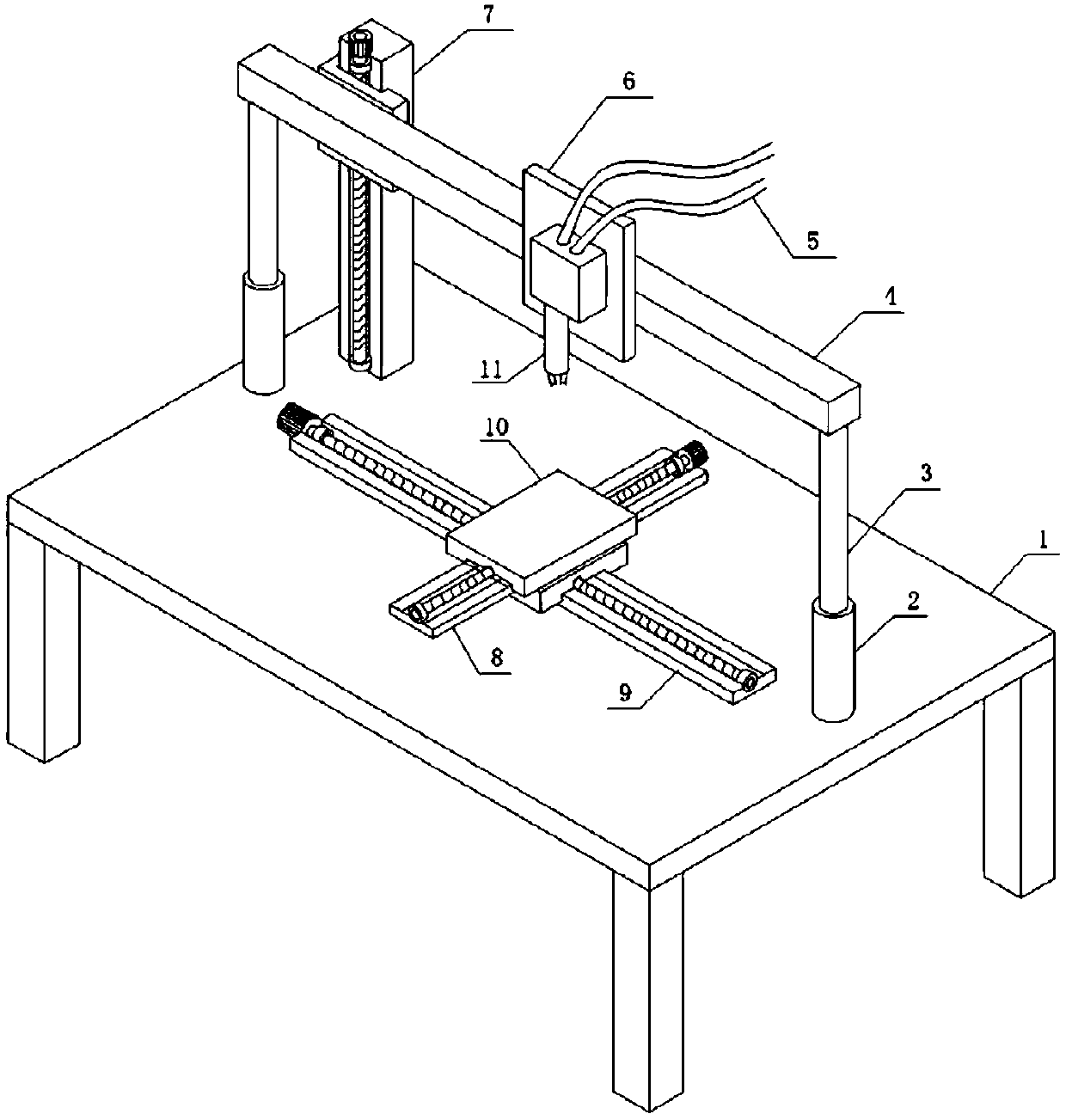

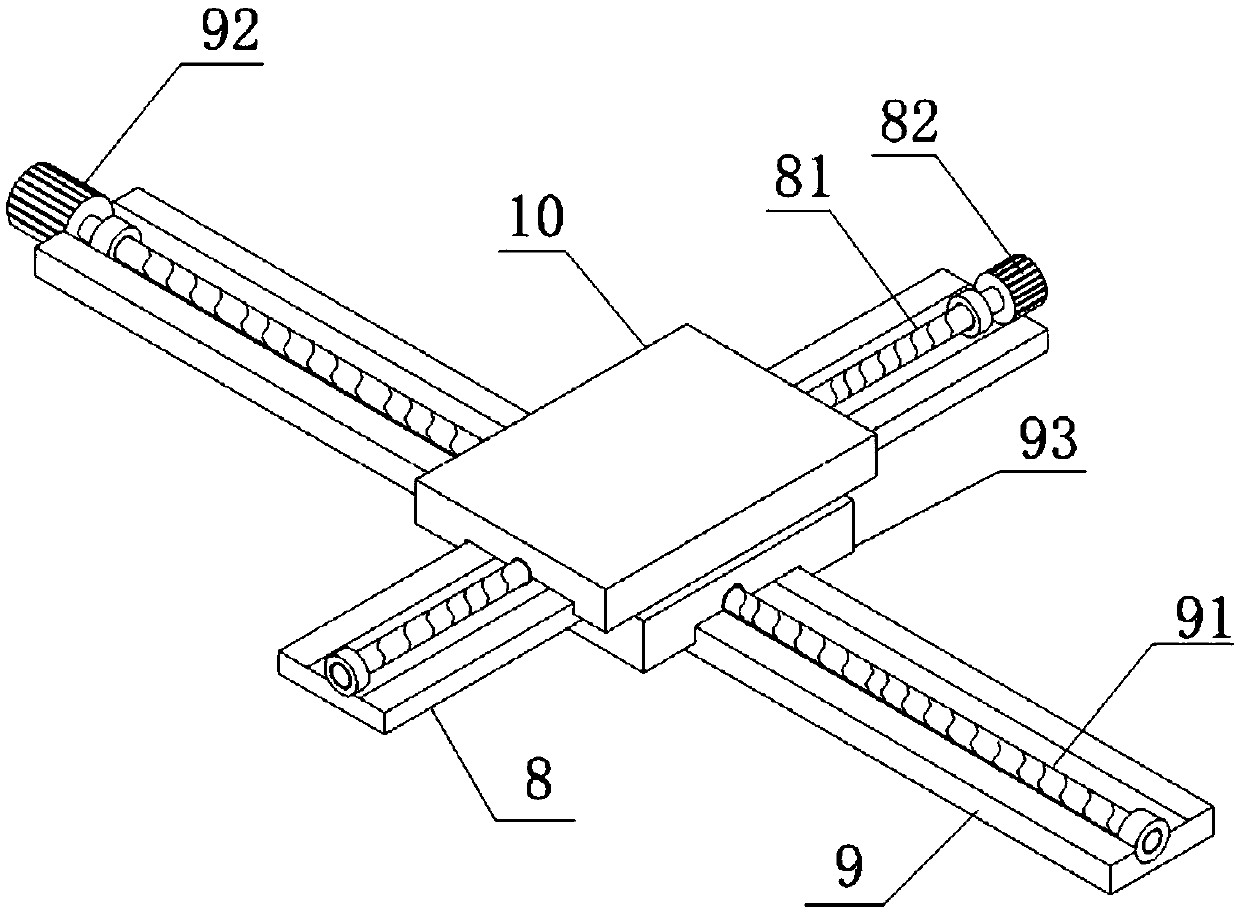

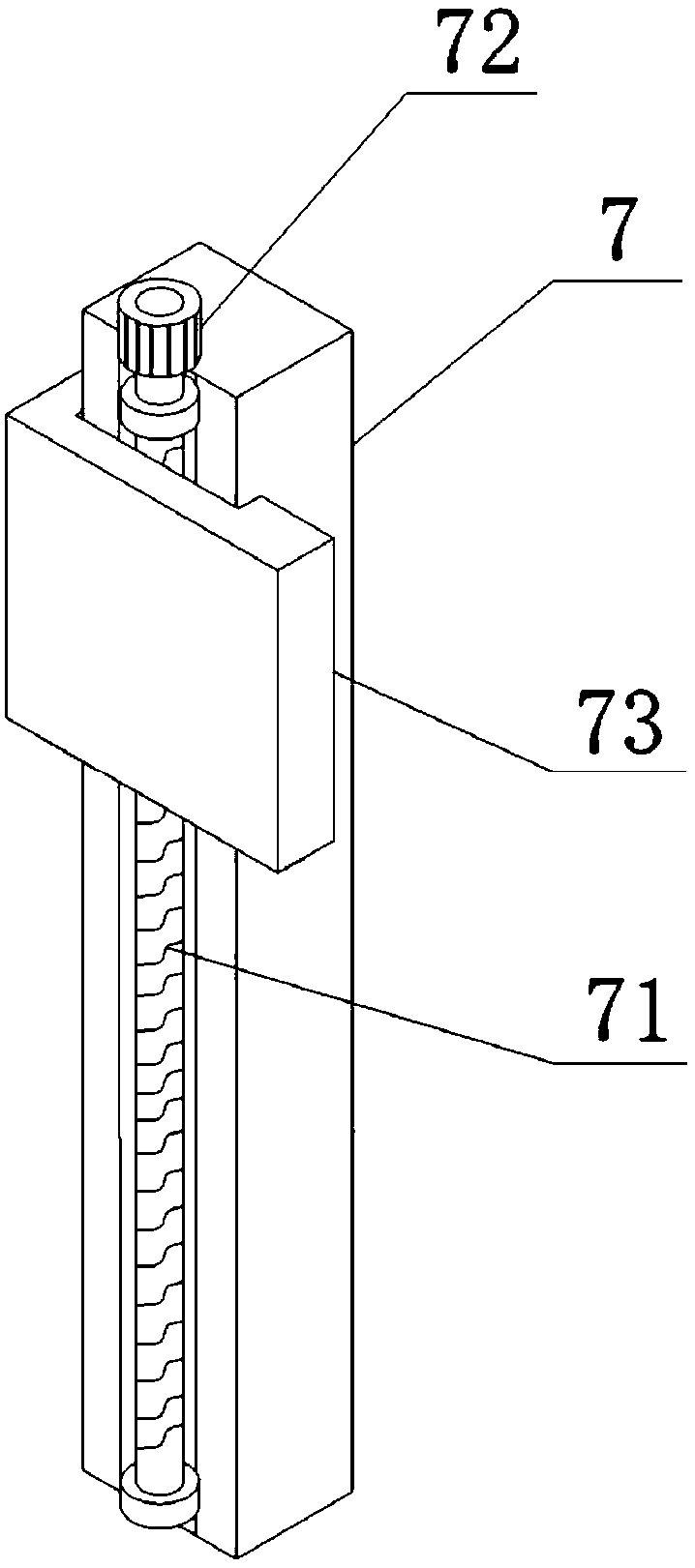

[0038] The present invention provides such Figure 1 to Figure 8 A high-efficiency 3D printing device based on the characteristics of 3D printing materials is shown, including a support base 1 and a 3D printer body 6. The upper part of the support base 1 is fixed with a left and right moving slide rail 9, and the upper part of the left and right moving slide rail 9 is slidably installed with Move the slide rail 8 back and forth, the upper part of the slide rail 8 is slidingly installed with the mobile printing platform 10, the vertical moving slide rail 7 is installed on the support base 1, and the guide sleeve 2 is fixedly installed on the upper part of the support base 1, and the guide sleeve 2 A guide post 3 is plugged in the interior, and the upper end of the guide post 3 is fixedly connected with the lift frame 4. The 3D printer body 6 is fixedly installed on one side of the lift frame 4. The lower part of the 3D printer body 6 is fixedly connected with a fixed tube 11, an...

Embodiment 2

[0060] The difference from Example 1 is that the printing material pure aluminum material is replaced by carbon-containing iron material:

[0061] When an efficient 3D printing device based on the characteristics of 3D printing materials of the present invention is actually used, it specifically includes the following steps:

[0062] S1: Check the equipment, check the remaining gas volume of the nitrogen tank 23, check the anti-rust oil volume of the anti-rust oil tank 20, check whether the electric melting furnace 26 is working normally, put the block or powder carbon-containing iron material into the crucible 27, Start the electric melting furnace 26 for melting, and after a period of time, confirm whether the furnace temperature and the molten liquid meet the production requirements;

[0063] S2: gas replacement, close the airtight door 15 on the transparent box 12, open the air valve 25, pass nitrogen gas into the transparent box 12, and discharge the gas replacement of th...

Embodiment 3

[0068] The difference from Example 1 is that the printing material pure aluminum is replaced by a zinc-magnesium alloy material:

[0069] When an efficient 3D printing device based on the characteristics of 3D printing materials of the present invention is actually used, it specifically includes the following steps:

[0070] S1: Check the equipment, check the remaining gas volume of the nitrogen tank 23, check the anti-rust oil volume of the anti-rust oil tank 20, check whether the electric melting furnace 26 is working normally, put the block or powder zinc-magnesium alloy material into the crucible 27, start The electric melting furnace 26 is melted, and after a period of time, it is confirmed whether the furnace temperature and the molten liquid meet the production requirements;

[0071] S2: gas replacement, close the airtight door 15 on the transparent box 12, open the air valve 25, pass nitrogen into the transparent box 12, discharge the gas replacement of the transparent b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com