Brown sugar sweet drinking granule and preparation method thereof

A technology for brown sugar and granules, applied in the field of brown sugar Ganyin granules and their preparation, can solve the problems of underutilization of raw materials, difficulty in grasping process parameters, loss of effective components, etc., and achieves simple and controllable preparation processes, simple and environmentally friendly processes, and no The effect of sediment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

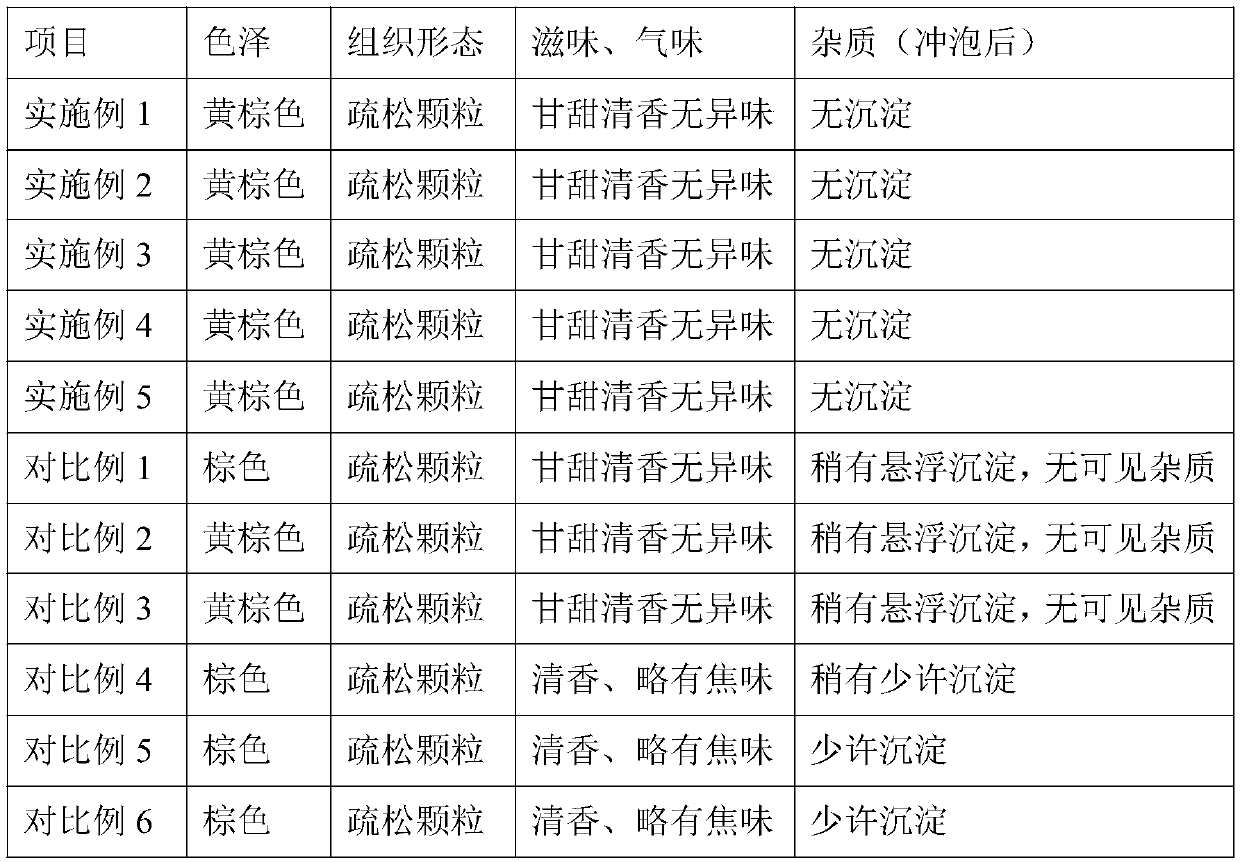

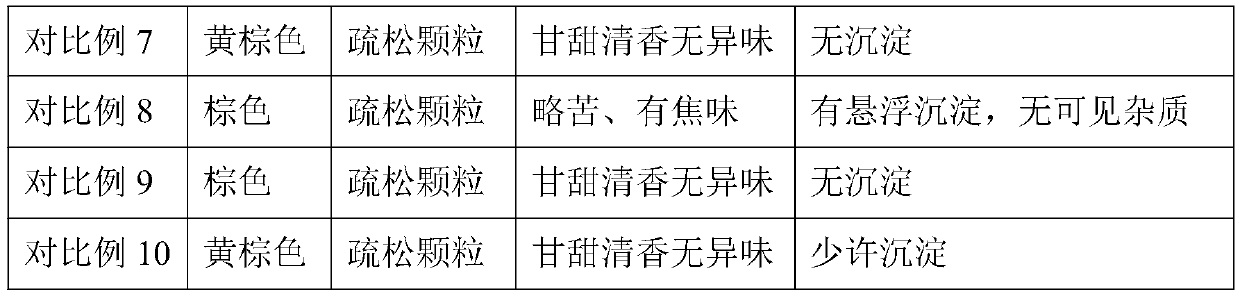

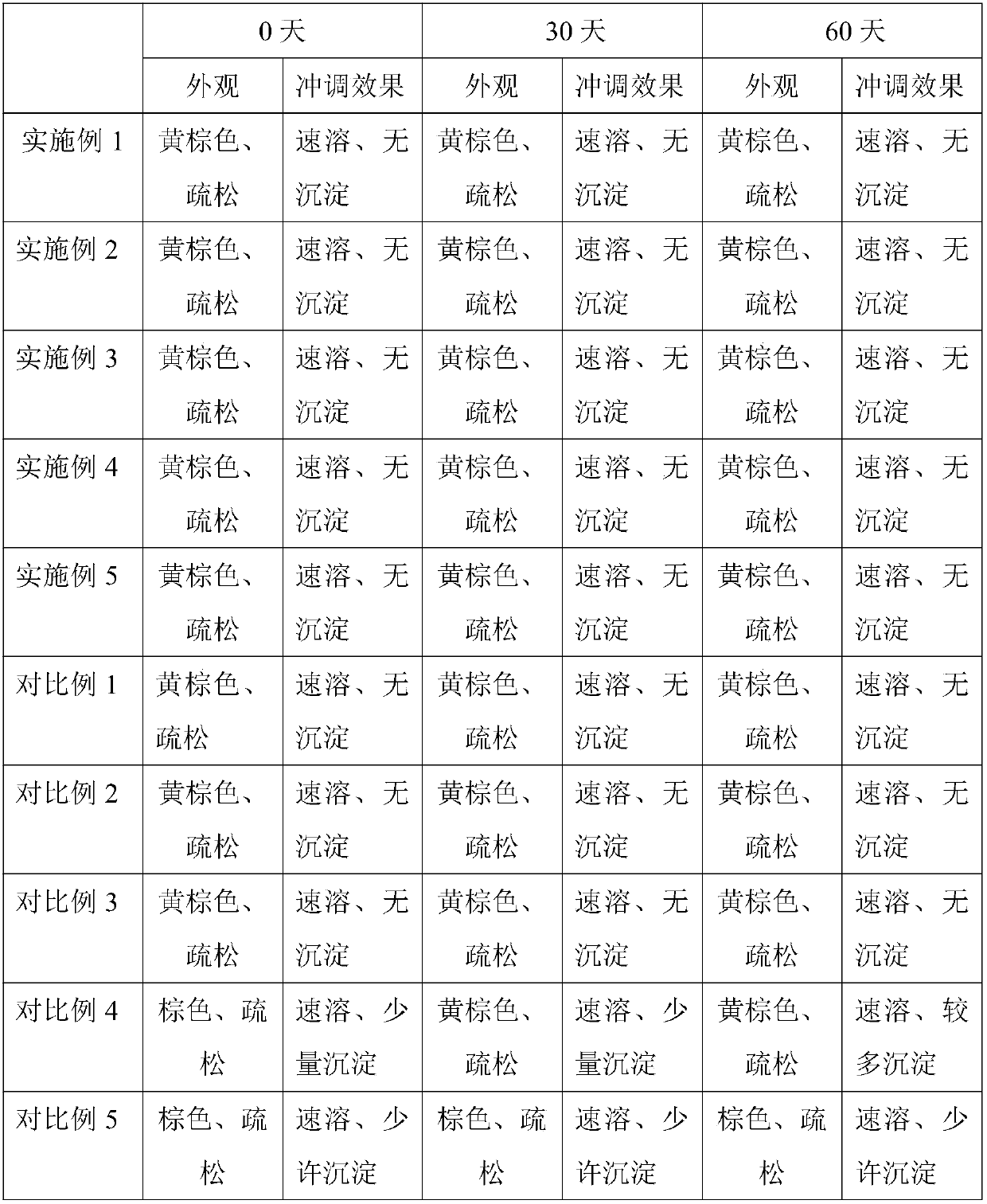

Examples

Embodiment 1

[0045] The method for the brown sugar and sweet drink granules provided in this embodiment specifically includes the following preparation steps:

[0046] S1. Raw material processing: weigh brown sugar, ginger powder, chrysanthemum powder, xylo-oligosaccharide powder, and snakehead grape leaf powder, pulverize them respectively, and pass through a 80-mesh sieve;

[0047] S2. Extraction: mix 12 parts of ginger powder obtained in step S1, 10 parts of chrysanthemum powder, and 2 parts of snakehead grape leaf powder into a supercritical carbon dioxide extractor, add 1 part of ethanol, set the extraction pressure and extraction temperature, and repeat Extract 3 times, each extraction is 30min, the carbon dioxide flow rate is 20L / h, and the extract is obtained; the first extraction pressure is 20MPa, the extraction temperature is 40°C, the second extraction pressure is 12MPa, and the extraction temperature is 35°C , the third extraction pressure is 4MPa, and the extraction temperatu...

Embodiment 2

[0052] The method for the brown sugar and sweet drink granules provided in this embodiment specifically includes the following preparation steps:

[0053] S1. Raw material processing: weigh brown sugar, ginger powder, chrysanthemum powder, xylo-oligosaccharide powder, and snakehead grape leaf powder, pulverize them respectively, and pass through a 90-mesh sieve;

[0054] S2. Extraction: Mix 6 parts of ginger powder, 5 parts of chrysanthemum powder, and 1 part of snake-toothed grape leaf powder obtained in step S1, then pass it into a supercritical carbon dioxide extractor, add 0.5 part of ethanol, set the extraction pressure and extraction temperature, and repeat Extract 3 times, each extraction is 35min, the carbon dioxide flow rate is 22L / h, and the extract is obtained; the first extraction pressure is 22MPa, the extraction temperature is 42°C, the second extraction pressure is 14MPa, and the extraction temperature is 38°C , the third extraction pressure is 6MPa, and the ext...

Embodiment 3

[0059] The brown sugar and sweet drink granules provided in this example specifically include the following preparation steps:

[0060] S1. Raw material processing: weigh brown sugar, ginger powder, chrysanthemum powder, xylo-oligosaccharide powder, and snakehead grape leaf powder, pulverize them respectively, and pass through a 90-mesh sieve;

[0061] S2. Extraction: mix 6 parts of ginger powder obtained in step S1, 5 parts of chrysanthemum powder, and 1 part of snakehead grape leaf powder into a supercritical carbon dioxide extractor, add 0.5 parts of water, set the extraction pressure and extraction temperature, and repeat Extract 3 times, each extraction 40min, the carbon dioxide flow rate is 30L / h, and the extract is obtained; the first extraction pressure is 25MPa, the extraction temperature is 46°C, the second extraction pressure is 16MPa, and the extraction temperature is 40°C , the third extraction pressure is 8MPa, and the extraction temperature is 30°C;

[0062] S3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com