Polyamide-based film and method for producing the same

A polyamide-based film and polyamide-based technology, applied in the direction of chemical instruments and methods, flat products, and other household appliances, can solve the problem of unsatisfactory uniformity of stretched film thickness, unsatisfactory dimensional stability, and metal foil breakage , low productivity and other issues, to achieve the effect of being beneficial to economic cost, preventing breakage, and excellent uniformity of thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0197] The preparation itself of the melt-kneaded product may be carried out according to a known method. For example, a raw material containing at least one of a polyamide resin, an organic lubricant and an inorganic lubricant is put into an extruder equipped with a heating device, heated to a predetermined temperature and melted, and the melt kneaded by a T-die The product is extruded, cooled and solidified with a casting drum or the like, thereby obtaining an unstretched sheet as a sheet-shaped molded product.

[0198] The order of adding the polyamide resin, organic lubricant, inorganic lubricant, etc. is not particularly limited. Furthermore, the average thickness of the unstretched sheet is not particularly limited, but it is usually about 15 to 250 μm, and particularly preferably 50 to 235 μm. By setting it in such a range, a stretching process can be implemented more efficiently.

[0199] stretching process

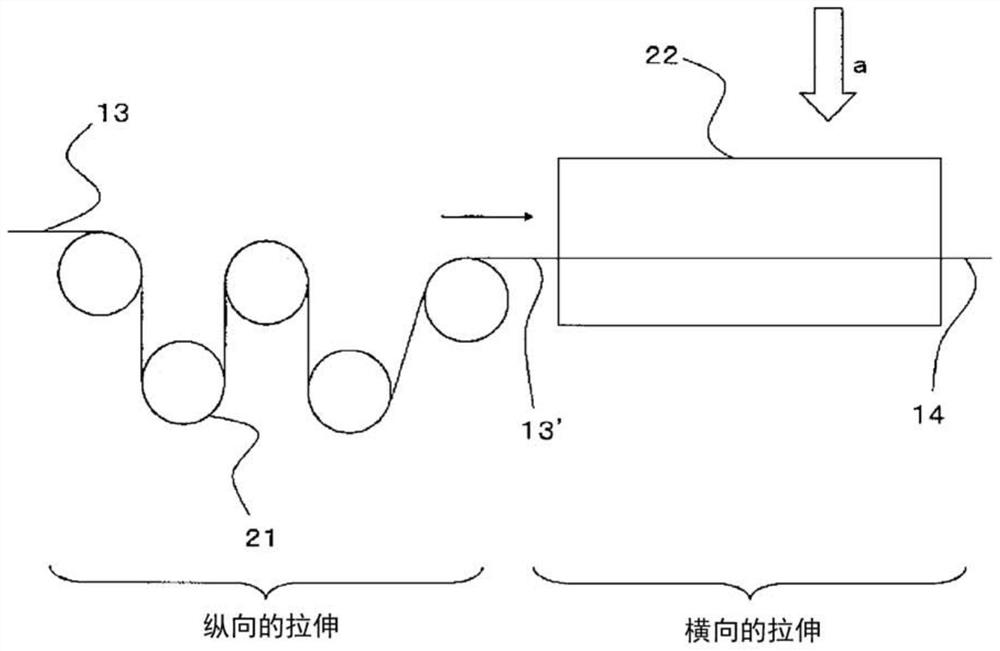

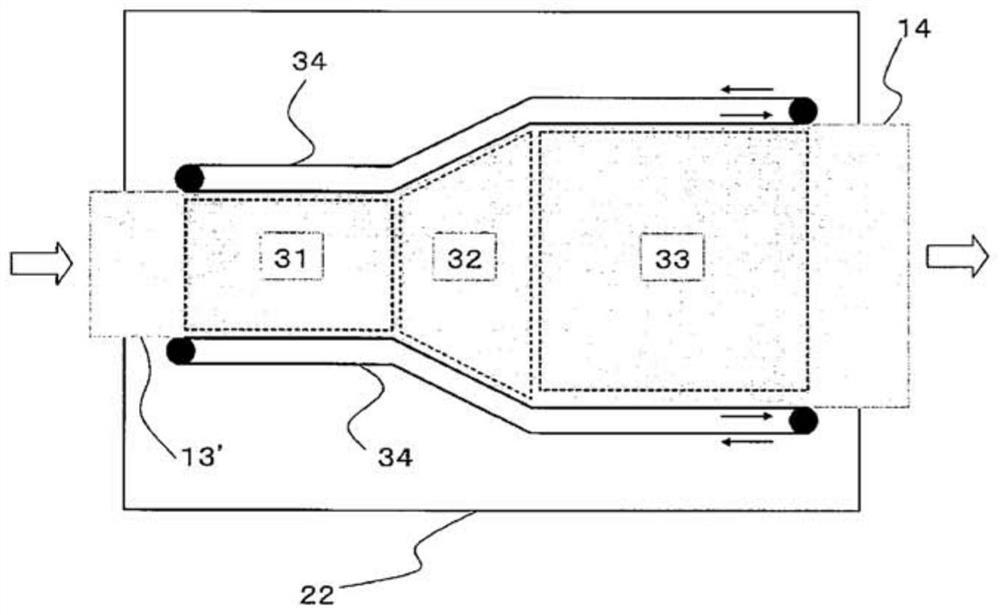

[0200] In the stretching step, the unstretched sheet is s...

Embodiment 1

[0233] (1) Manufacture of polyamide film

[0234] First, the ingredients shown in Table 1 were used as raw materials.

[0235] [Table 1]

[0236]

[0237] Using the above raw materials, polyamide resin (polyamide 6 resin) / polyamide resin containing silica / polyamide resin containing organic lubricant = 91.5 parts by mass / 2.5 parts by mass / 6.0 parts by mass during extrusion After melting and kneading in the machine, it was supplied to a T-die and discharged into a sheet form, wound up on a metal drum whose temperature was adjusted to 20° C., cooled and wound up to produce an unstretched sheet. At this time, the supply amount of the polyamide resin and the like were adjusted so that the thickness of the polyamide-based film obtained after stretching was 12 μm.

[0238] Next, the resulting unstretched sheet is subjected to a stretching step by sequential biaxial stretching. More specifically, by using figure 2 The apparatus shown is implemented by stretching TD with a tent...

Embodiment 2~40

[0244] Embodiment 2~40, comparative example 1~20

[0245] In addition to changing the production conditions and the target thickness of the polyamide-based film after stretching to those shown in Tables 2 to 4, and changing the composition ratio of the raw materials so that the content of the organic lubricant or inorganic lubricant is as shown in Tables 8 to 10 In addition, a polyamide-based film was obtained in the same manner as in Example 1. Using the obtained polyamide-based film, a laminate was produced in the same manner as in Example 1. Among them, Embodiment 7, Embodiment 17, and Embodiment 38 are more specifically modified as follows.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com