Molybdenum carbide/carbon composite material, and preparation method and application thereof

A carbon composite material and composite material technology, applied in the field of molybdenum carbide/carbon composite material and its preparation, can solve the problems of molybdenum carbide composite materials to be developed, achieve excellent cycle stability, high electronic conductance and ion conductance, easy to obtain Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

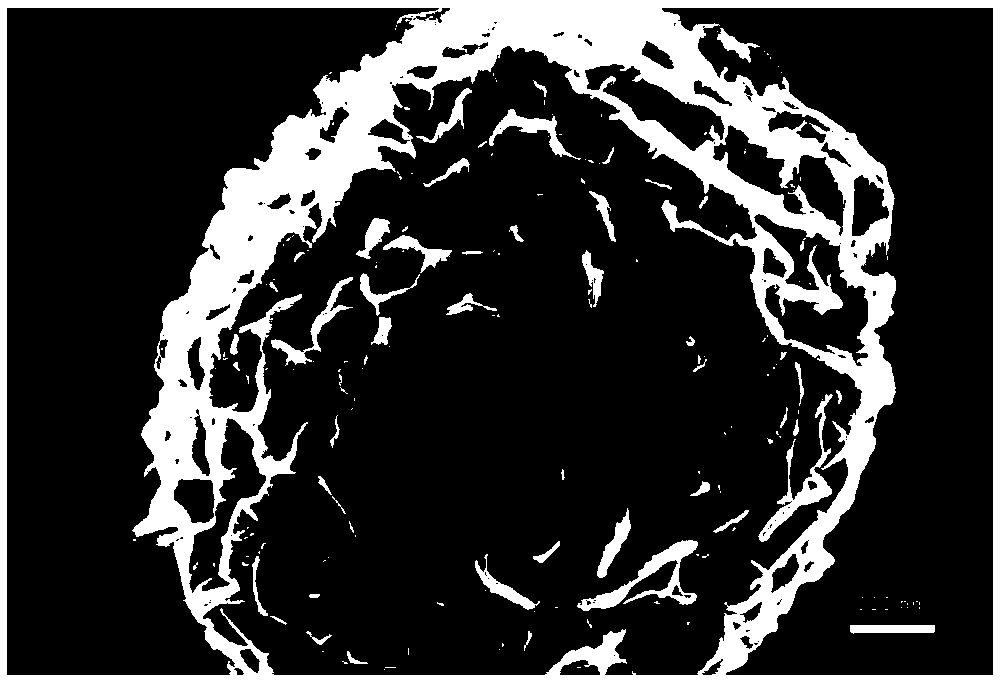

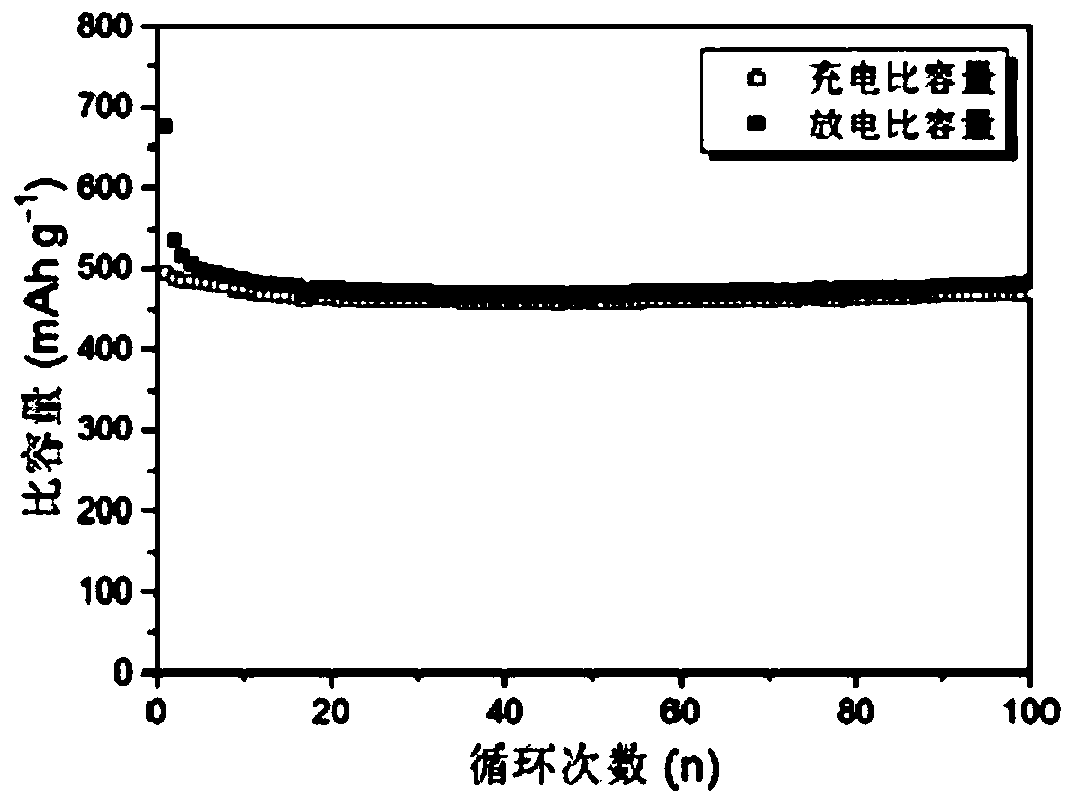

Image

Examples

Embodiment 1

[0051] This embodiment provides a method for preparing a molybdenum carbide / carbon composite material, the preparation method comprising the following steps:

[0052] (1) Dissolve a certain amount of ammonium molybdate, copper chloride, and urea in deionized water, stir evenly, and make a clear and transparent solution a, wherein the concentration of molybdenum source is 0.1mM, Mo / Cu molar ratio=0.01:1 , the concentration of urea in the mixture is 0.2g / mL; after the solution a is stirred evenly, it is placed in a hydrothermal tank and heated in an oven at 150°C for 1 hour to obtain a precipitate; the solid-liquid separation of the obtained precipitate is performed with deionized water and Washed with alcohol several times, dried in an oven at 90°C to obtain the precursor;

[0053] (2) Put the precursor obtained in step (1) in a tube furnace, pass through acetylene gas, and heat-treat at 1000 ° C for 1 h to obtain Mo 2 C / Cu / C composite material;

[0054] (3) Mo obtained by st...

Embodiment 2

[0060] This embodiment provides a method for preparing a molybdenum carbide / carbon composite material, the preparation method comprising the following steps:

[0061] (1) A certain amount of ammonium molybdate, cupric chloride, urea are dissolved in deionized water, stir evenly, make clear transparent solution a, wherein the concentration of molybdenum source is 5mM, Mo / Cu mol ratio=10:1, The concentration of urea in the mixture is 100g / mL; after stirring solution a evenly, place it in a hydrothermal tank and heat it in an oven at 200°C for 12 hours to obtain a precipitate; separate the obtained precipitate from solid and liquid, and wash it with deionized water and alcohol Repeatedly, dry in an oven at 50°C to obtain the precursor;

[0062] (2) Put the precursor obtained in step (1) in a tube furnace, pass through acetylene gas, and heat-treat at 700°C for 12h to obtain Mo 2 C / Cu / C composite material;

[0063] (3) Mo obtained by step (2) 2 The C / Cu / C composite material is ...

Embodiment 3

[0067] This embodiment provides a method for preparing a molybdenum carbide / carbon composite material, the preparation method comprising the following steps:

[0068] (1) A certain amount of ammonium molybdate, cupric chloride, urea are dissolved in deionized water, stir evenly, make clear transparent solution a, wherein the concentration of molybdenum source is 2mM, Mo / Cu mol ratio=0.2:1, The concentration of urea in the mixture is 60g / mL; after stirring solution a evenly, place it in a hydrothermal tank and heat it in an oven at 160°C for 2 hours to obtain a precipitate; separate the solid and liquid of the obtained precipitate, and wash it with deionized water and alcohol Repeatedly, dry in an oven at 60°C to obtain the precursor;

[0069] (2) Place the precursor obtained in step (1) in a tube furnace, pass through acetylene gas, and heat-treat at 800°C for 2 hours to obtain Mo 2 C / Cu / C composite material;

[0070] (3) Mo obtained by step (2) 2 The C / Cu / C composite mater...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com