Easily-demoulded aluminum alloy template and preparing method thereof

An aluminum alloy formwork and easy demoulding technology, which is applied to the field preparation of formwork/formwork components, building components, electrolytic coatings, etc., can solve the problems of poor hydrophobicity of the release agent, damage to the concrete surface, and easy adhesion to concrete, etc. , to achieve the effect of improving the demoulding quality, easy demoulding, and more recycling times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

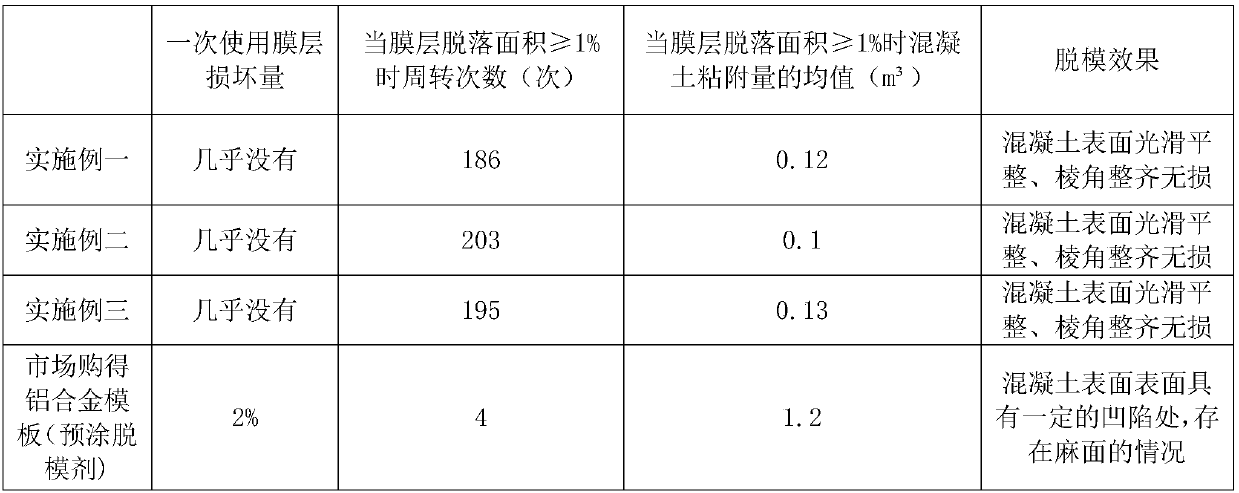

Examples

Embodiment 1

[0033] Preparation of modified shell powder: After washing the shells with deionized water, soak them in 0.1mol / L sodium hydroxide solution for 30 minutes, then place them in 0.1mol / L nitric acid solution, and place them in a water bath at 60°C After heating and refluxing for 5 hours, take it out, wash it with deionized water to neutrality, dry and grind to obtain pretreated shell powder, then add the pretreated shell powder into an ethanol solution with a mass ratio of 5 times, and use 800r / Min mechanically stirred at a speed of 5 min, and dropwise added polymethyl methacrylate with a mass ratio of 2 times that of shell powder at a speed of 2-3 drops / min. After the addition was completed, continue to stir and mix for 70 minutes. Ultrasound for 10 minutes under the condition, filter and dry to obtain the modified shell powder.

[0034]Preparation of silica particles: Dissolve 10g of tetraethyl silicate in ethanol solution, stir for 30min at a speed of 50r / min, add 0.1mol / L po...

Embodiment 2

[0041] The preparation of modified shell powder is the same as in Example 1.

[0042] Preparation of silica particles: Dissolve 10g of tetraethyl silicate in ethanol solution, stir for 20min at a speed of 80r / min, add 0.1mol / L potassium hydroxide solution to adjust the pH to 6.0, then add 1g of polyamide Imine particles were ultrasonically dispersed for 30 minutes under the conditions of 20KHz and 120W, and then the reaction solution was placed in an autoclave at 220°C for 24 hours of heat preservation and reaction. After the reaction was completed, it was filtered and washed 2 to 3 times with deionized water to obtain a solid After the product was dried, it was placed in a calciner, and calcined at 550°C for 4 hours. It was found that the silicon dioxide particles had a porous rosette-like hierarchical structure after scanning with a SEM scanning electron microscope.

[0043] Preparation of modified silica: Take 10g of dodecyltriethoxysilane and add it to 2% ethanol solution ...

Embodiment 3

[0049] The preparation of modified shell powder is the same as in Example 1.

[0050] Preparation of silica particles: Dissolve 10g of tetraethyl silicate in ethanol solution, stir for 25min at a speed of 100r / min, add 0.1mol / L potassium hydroxide solution to adjust the pH to 6.0, and then add 1g polyamide Imine particles were ultrasonically dispersed for 30 minutes under the conditions of 20KHz and 120W, and then the reaction solution was placed in an autoclave at 220°C for 24 hours of heat preservation and reaction. After the reaction was completed, it was filtered and washed 2 to 3 times with deionized water to obtain a solid After the product was dried, it was placed in a calciner and calcined at 600°C for 6 hours. Scanning by SEM scanning electron microscope revealed that the silicon dioxide particles had a porous rosette-like hierarchical structure.

[0051] Preparation of modified silica: Take 10g of dodecyltriethoxysilane and add it to 2% ethanol solution for hydrolysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com