High-yield ethyl lactate saccharomyces cerevisiae strain

A technology of ethyl lactate and Saccharomyces cerevisiae, which is applied in the field of bioengineering, can solve the problem of low ability to synthesize ethyl lactate, achieve the effect of increasing the production amount and increasing ethyl lactate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Construction of high-yield ethyl lactate Saccharomyces cerevisiae strain

[0031] The main construction process of the strain is as follows:

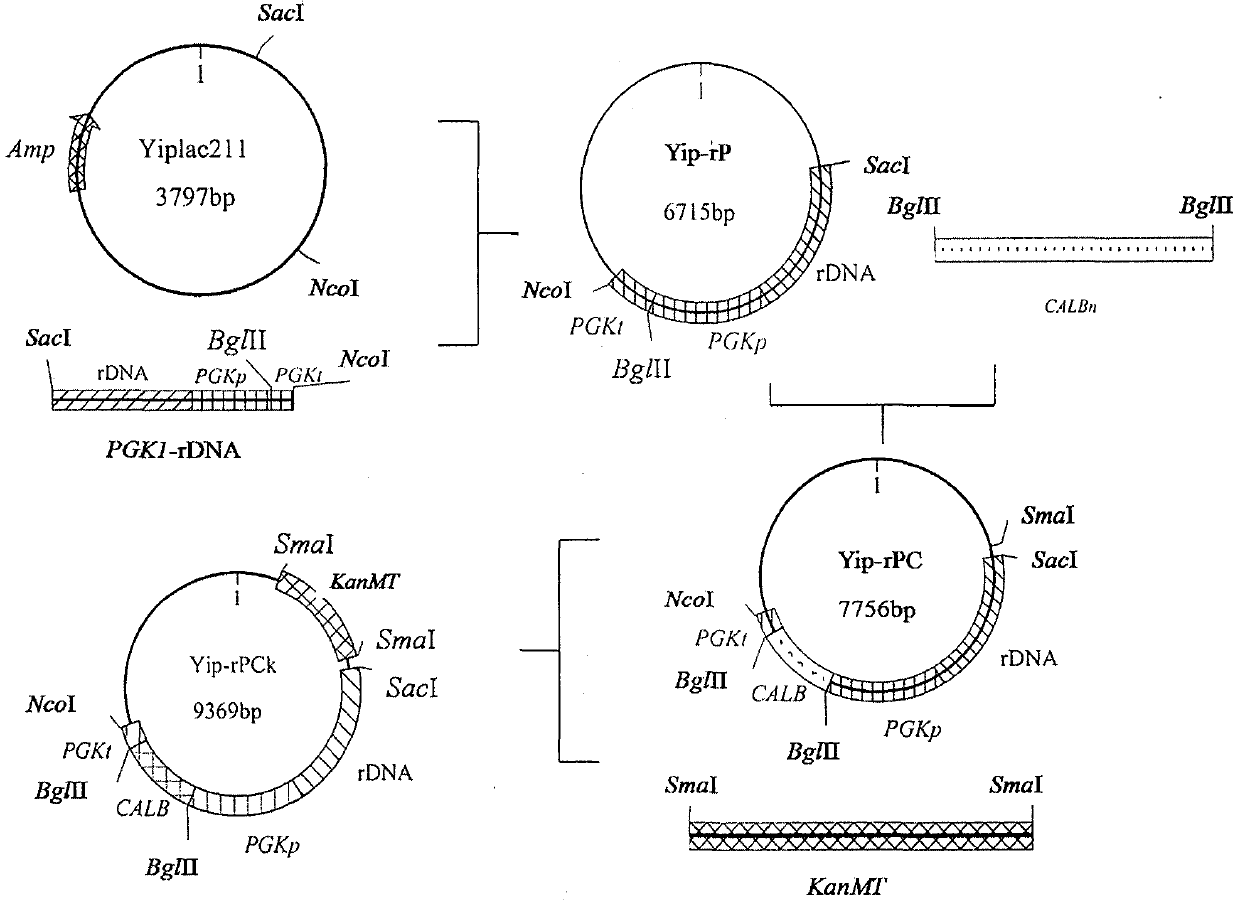

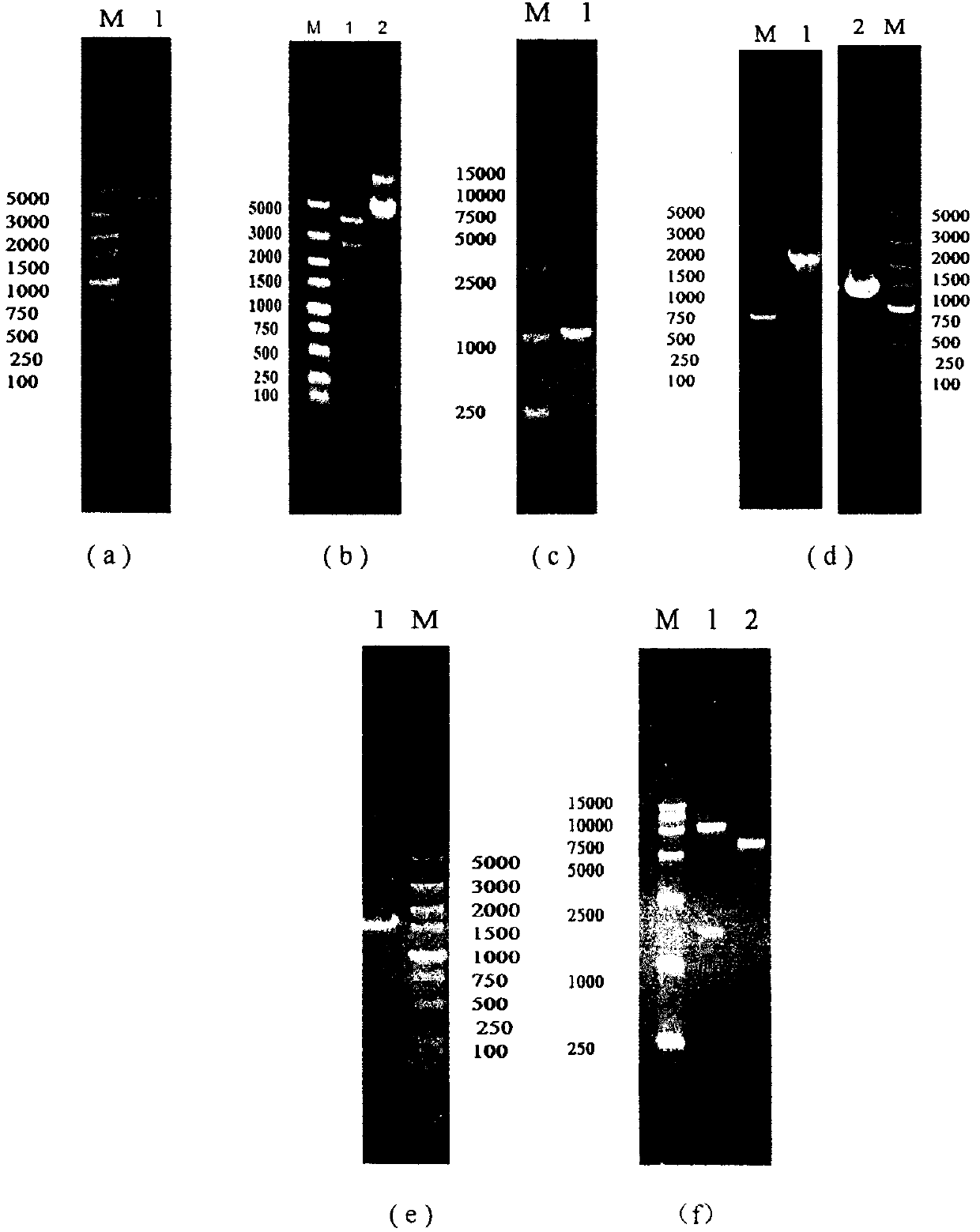

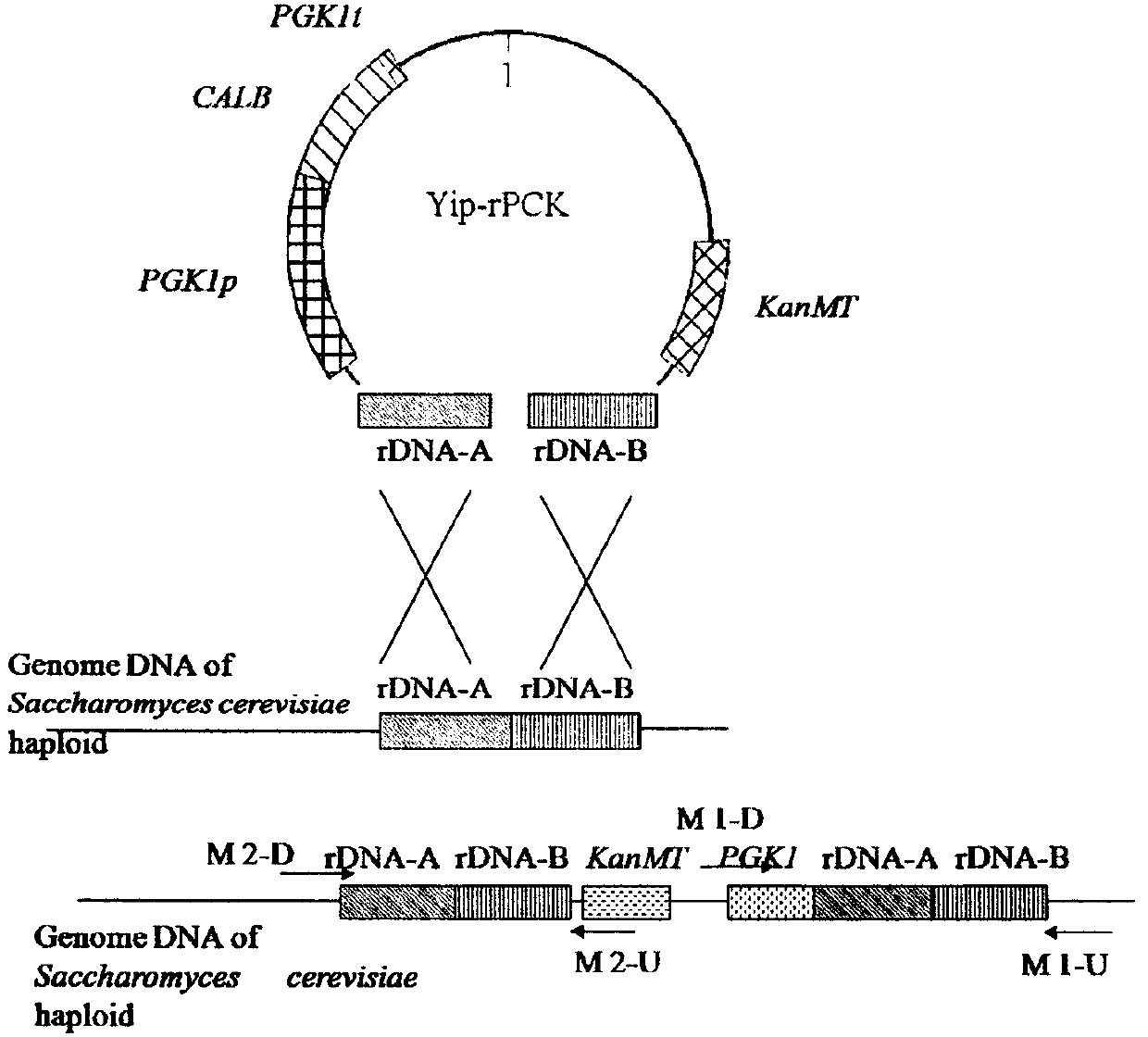

[0032] Yip-rPCk was constructed based on the plasmid Yip-lac211, see the plasmid construction procedure figure 1. First, the α5 genome of the haploid strain of Saccharomyces cerevisiae CICC32315 was used as a template, and the rDNA (SEQNO: 2) fragment, 2269bp, was amplified by PCR using primers rDNA-U and rDNA-D. The laboratory-preserved plasmid Yep-PGK was used as a template, and PGK-U and PGK-D were used as primers to amplify the PGK1 fragment with a length of 1771 bp. The rDNA and PGK1 were connected together by fusion PCR to obtain PGK1-rDNA, and were ligated to the plasmid Yip-lac211 by SacI and NcoI to obtain Yip-rP. Using the Yep-PCnK plasmid as a template, primers CALB-U and CALB-D, the target fragment CALBn (SEQ NO: 1) was obtained by PCR, which was ligated to Yip-rP using BglII single enzyme digestion t...

Embodiment 2

[0039] Example 2: Fermentation experiment of multi-copy strain sorghum raw material semi-solid liquor

[0040] 1) Fermentation process roadmap:

[0041] Sorghum → soaking → liquefaction → saccharification → cooling → mixing koji, inoculation with lactic acid bacteria → cultivation for 24 hours → fermentation → distillation

[0042] 2) Process conditions: soaking conditions: 60-70°C, fully absorb water; cooking conditions: 121°C for about 30 minutes; liquefaction conditions: 85-90°C, high temperature resistant α-amylase, liquefaction for 60 minutes; saccharification conditions: 55-60°C , add glucoamylase, saccharification for 30min; fermentation conditions: 30°C, 6 days; wine steaming conditions: 100mL fermentation broth, add 100mL water, steam 100mL wine sample.

[0043] 3) Ingredients: sorghum flour: 78g; add water 200mL; high temperature resistant α-amylase: 25μL; glucoamylase: 45μL; Daqu 12g;

[0044] Carry out semi-solid Daqu liquor fermentation experiments on Saccharomy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com