Genetically engineered bacterium with low yield of 2-phenethyl alcohol and application of genetically engineered bacterium

A genetically engineered bacterium and gene technology, applied in the field of Saccharomyces cerevisiae genetically engineered bacteria with low production of 2-phenylethanol, can solve the problems of high 2-phenylethanol content and low production of 2-phenylethanol, etc., to reduce 2-phenylethanol, improve Good flavor, fermentation performance and growth performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

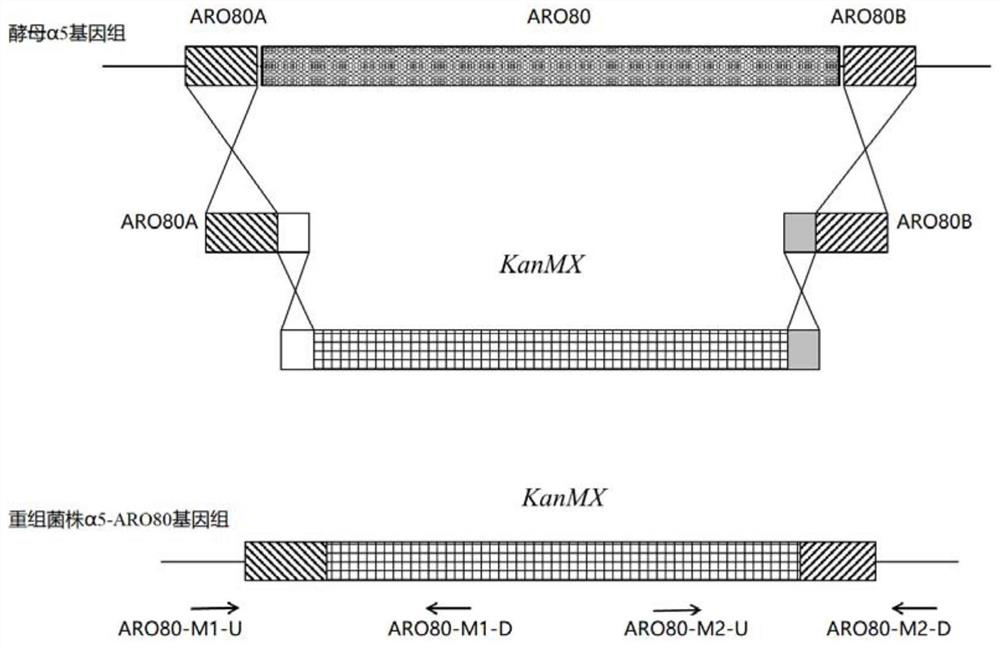

[0031] Example 1: Construction of Saccharomyces cerevisiae Strains Deleting the ARO80 Gene

[0032] Taking Saccharomyces cerevisiae α5 (Li, W., Wang, J.H., Zhang, C.Y., Ma, H.X., & Xiao, D.G. (2017). Regulation of Saccharomyces cerevisiae genetic engineering on the production of acetate esters and higher alcohols during Chinese Baijiufermentation. Journal of industrial microbiology&biotechnology, 44(6), 949–960. https: / / doi.org / 10.1007 / s10295-017-1907-2) was used as the host bacteria, and a recombinant genetically engineered strain lacking the ARO80 gene was constructed by homologous recombination.

[0033] The specific construction steps are detailed as follows:

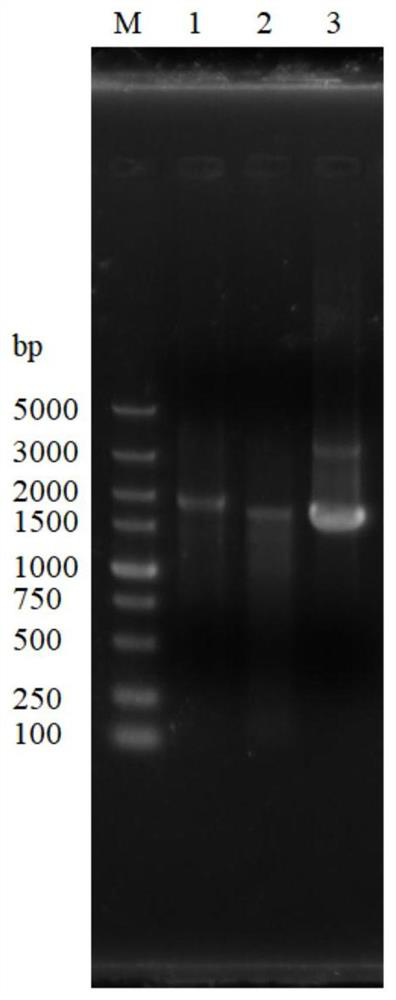

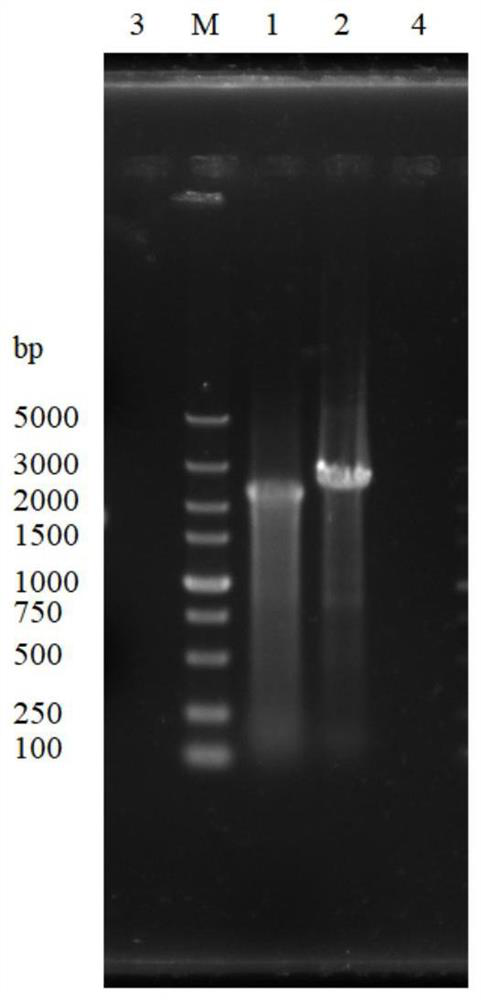

[0034] (1) Using the genome of the starting strain Saccharomyces cerevisiae α5 as a template, using ARO80A-F and ARO80A-R as primers, the upstream DNA molecular fragment ARO80A (1779bp) of the ARO80 gene was obtained by PCR amplification; using the Saccharomyces cerevisiae α5 genome as a template, Using ARO80B-F an...

Embodiment 2

[0046] Example 2: Recombinant strain α5-ΔARO80-k-p liquor fermentation experiment in liquid state

[0047] (1) Fermentation process route:

[0048] Sorghum granules→crushing→liquefaction, saccharification→adding acid protease→cooling→filtering→adjustment of sugar content of sorghum juice→subpackaging→sterilization→inoculation, fermentation→distillation;

[0049] (2) The main process conditions are as follows:

[0050] Grinding conditions: the degree of crushing is suitable for sorghum without whole grains, and the degree of crushing should not be too fine, so as not to cause excessive filtration pressure;

[0051] Liquefaction and saccharification conditions: add crushed sorghum to warm water at 30°C at a material-to-water ratio of 1:4, stir well, place in a constant temperature water bath, keep at 90°C for 60 minutes, and liquefy. Adjust the temperature of the water bath to 60°C and keep it for 30 minutes for saccharification. Fully stir once every 5 minutes during liquefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com