Ultrahigh strength corrosion resistant composite ceramic fracturing propping agent

A fracturing proppant and composite ceramic technology, which is applied in drilling compositions, production fluids, wellbore/well components, etc., can solve the problem of reduced pressure resistance and corrosion resistance of proppant, and can not meet the long-term downhole bearing capacity. In order to reduce the mining cost and construction difficulty, good sphericity and smoothness, and low turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

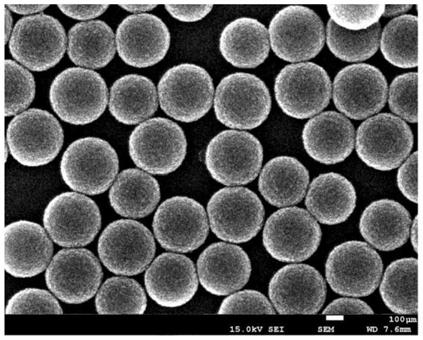

Image

Examples

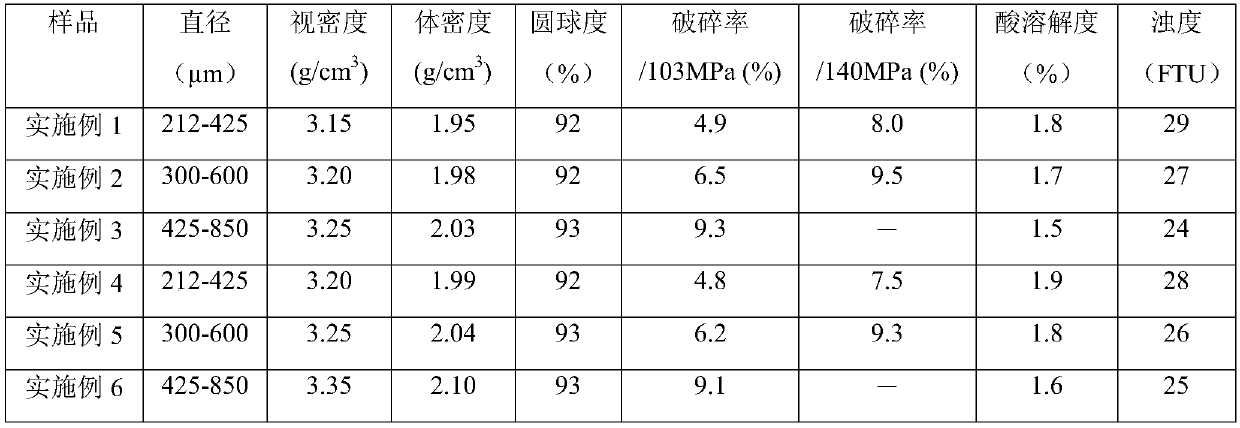

Embodiment 1

[0030] 1) Ingredients: according to 83wt% high-purity ultra-fine Al 2 o 3 , 3wt% ultrafine kaolin, 10wt% ultrafine ZrO 2 , 1wt% CaO, 0.5wt% SiO 2 , 0.5wt% MgO and 2wt% lignin were weighed.

[0031] 2) Mixing: Add the material in the barrel in step 1) into a three-dimensional stereo mixer and mix for 3.5 hours.

[0032] 3) trapped material: add 7wt% water to the material mixed in step 2) on a pan granulator for mixing, and mix evenly and trap the material for 48 hours.

[0033] 4) Granulation: transfer the material in step 3) to a dual-power powerful granulator, add an aqueous solution containing 8 wt% glycerin and 1-1.5 wt% povidone K90 for water spray granulation.

[0034] 5) Shaping and densification: Transfer the material in step 4) to a tilting sugar coating machine, and treat it at 70°C for 3 hours to remove moisture and gas, and increase the density, sphericity and smoothness of the semi-finished product.

[0035]6) Screening: sieving the encrypted semi-finished pro...

Embodiment 2

[0038] 1) batching: carry out according to embodiment 1.

[0039] 2) mixing: carry out according to embodiment 1.

[0040] 3) sleepy material: carry out according to embodiment 1.

[0041] 4) Granulation: Carry out according to Example 1.

[0042] 5) Shaping encryption: Carry out according to embodiment 1.

[0043] 6) Screening: The encrypted material obtained in step 5) is screened with a 30-50 mesh sieve machine to obtain an encrypted semi-finished product with a required particle size.

[0044] 7) Sintering: according to Example 1, an ultra-high-strength corrosion-resistant composite ceramic fracturing proppant with a particle size of 300-600 μm can be obtained.

Embodiment 3

[0046] 1) batching: carry out according to embodiment 1.

[0047] 2) mixing: carry out according to embodiment 1.

[0048] 3) sleepy material: carry out according to embodiment 1.

[0049] 4) Granulation: Carry out according to Example 1.

[0050] 5) Shaping encryption: Carry out according to embodiment 1.

[0051] 6) Screening: The encrypted semi-finished product obtained in step 5) is screened with a 20-40 mesh sieve to obtain an encrypted semi-finished product with a required particle size.

[0052] 7) Sintering: according to Example 1, an ultra-high-strength corrosion-resistant composite ceramic fracturing proppant with a particle size of 425-850 μm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com