Medical silicone rubber with high mechanical property and preparation method thereof

A technology of mechanical performance and silicone rubber, which is applied in the field of high mechanical performance medical silicone rubber and its preparation, and can solve problems such as poor biocompatibility and irritating odor of vulcanized rubber

Active Publication Date: 2019-04-19

SHANDONG BRANDEN MEDICAL DEVICE

View PDF7 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method uses hexamethyldisilazane as a hydrophobic agent to treat silica as a filler in the compound and diphenylsilanediol as a structural control agent, but methyl vinyl silicone rubber and polyurethane are only added to vulcanization. It is difficult to vulcanize in the presence of a peroxide vulcanizing agent, even under heating, the vulcanized rubber formed has a pungent odor and poor biocompatibility

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0019] The present invention is specifically described and further illustrated by examples below, which cannot be construed as limiting the scope of the present invention. Those skilled in the art may make some non-essential improvements and adjustments based on the content of the present invention above.

[0020] The testing standard that embodiment adopts:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Tear strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Login to View More

Abstract

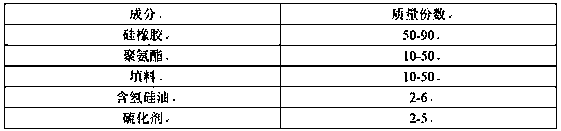

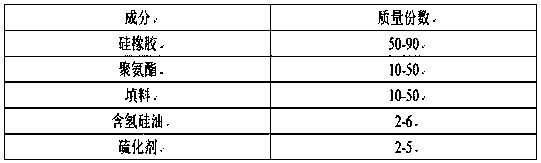

The invention relates to medical silicone rubber with high mechanical property and a preparation method thereof. The silicone rubber comprises the following raw materials, by weight: 50-90 parts of silicone rubber, 10-50 parts of polyurethane, 10-50 parts of a filling material, 2-6 parts of hydrogen-containing silicone oil, and 2-5 parts of a vulcanizing agent. The preparation method includes thefollowing steps: evenly mixing white carbon black with silicone rubber and polyurethane in an internal mixer, placing the mixed polyurethane on an open type rubber mixer, and adding the hydrogen-containing silicone oil, silicone rubber and vulcanizing agent in a small amount and a plurality of batches; and finally vulcanizing the rubber compound on a flat rubber vulcanizer at 150-190 DEG C for 5-15 min to obtain the medical silicone rubber with high mechanical property. The medical silicone rubber with high mechanical property has the characteristics of good mechanical property, no irritation,high safety and the like.

Description

technical field [0001] The invention relates to a medical silicone rubber with high mechanical performance and a preparation method thereof, belonging to the technical field of polymer materials. Background technique [0002] Silicone rubber is one of the most important products among silicone materials. Silicone rubber is mainly composed of linear polysiloxane (or base rubber, raw rubber), reinforcing filler, crosslinking agent, catalyst and other additives. Mix all the components uniformly and process it into rubber compound. After cross-linking (or vulcanization, curing) under certain conditions, the rubber compound will transform from the initial high-viscosity plastic state to an elastic state, that is, a three-dimensional Vulcanizate with network cross-linked structure. [0003] As we all know, silicone rubber has many unique and excellent properties, such as heat resistance, cold resistance, aging resistance (ozone aging resistance, thermal oxygen aging resistance, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L83/07C08L75/14C08L83/05C08K3/36

CPCC08L83/04C08L2205/025C08L75/14C08K3/36C08G77/20C08G77/12C08K3/26C08K5/56C08L83/00C08J3/20C08L2203/02C08L2205/03C08L2207/324C08L2312/00

Inventor 张海军袁坤山王如蒙鲁手涛刘黎明曹文瑞周超尹玉霞侯文博段翠海刘光

Owner SHANDONG BRANDEN MEDICAL DEVICE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com