A kind of acrylate emulsion for architectural interior wall paint and its preparation method and paint

A technology of acrylate and emulsion, applied in the direction of coating, etc., can solve the problems of increasing formula cost, etc., achieve excellent scrub resistance and freeze-thaw stability, low VOC content, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The embodiment of the present invention proposes a kind of preparation method of above-mentioned acrylic ester emulsion for architectural interior wall coating, comprises the following steps:

[0041] a) Pre-emulsification I: At normal temperature and pressure, mix 0.1-0.4 parts of reactive anionic emulsifier, 0.1-0.4 parts of reactive nonionic emulsifier and 20-30 parts of water in an emulsification tank, stir, and then add 5 parts in sequence -15 parts of butyl acrylate, 15-23 parts of styrene, 5-15 parts of isooctyl acrylate, 0.1-0.5 parts of self-crosslinking monomer, 0.1-2 parts of carboxyl monomer, 0.1-1 part of acrylamide, 0.01- 0.1 part of silane coupling agent, stirred to obtain pre-emulsion I;

[0042] b) Polymerization I: Add 0.1-0.4 parts of reactive anionic emulsifier, 0.1-0.4 parts of reactive nonionic emulsifier and 4.5-15 parts of water into the reactor, heat up to 80-87 °C, add 0.01-0.1 parts of After the sulfate reaction, start dripping persulfate sol...

Embodiment 1

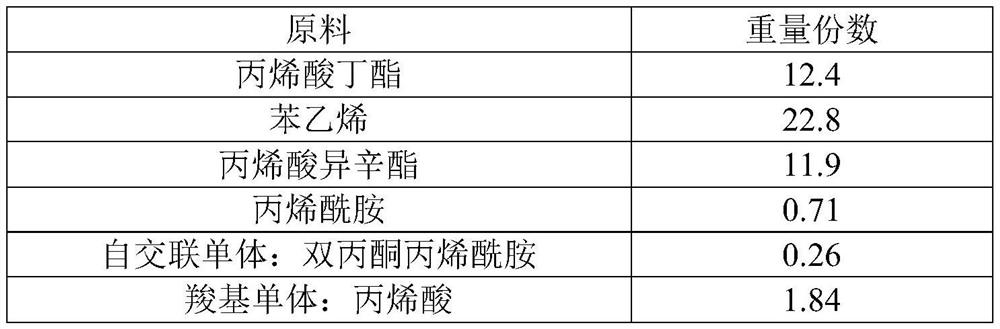

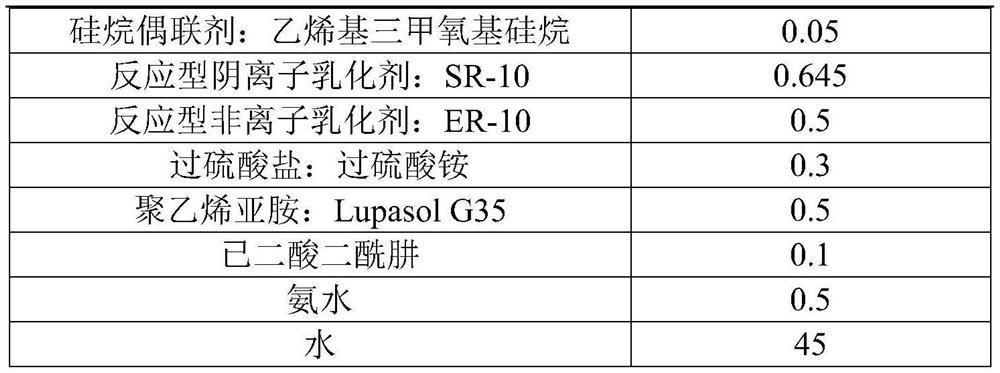

[0058] An acrylic ester emulsion for building interior wall paint is prepared by comprising the following raw materials in parts by weight:

[0059]

[0060]

[0061] The preparation method of above-mentioned acrylic acid ester emulsion for building interior wall paint, comprises the following steps:

[0062] a) Pre-emulsification I: At normal temperature and pressure, mix 0.3 parts of reactive anionic emulsifier, 0.17 parts of reactive nonionic emulsifier and 23.4 parts of water in an emulsification tank, stir well and dissolve evenly, and then add 10 parts of butyl acrylate in sequence Esters, 21.4 parts of styrene, 9.5 parts of isooctyl acrylate, 0.22 parts of self-crosslinking monomers, 1.25 parts of carboxyl monomers, 0.59 parts of acrylamide, 0.04 parts of silane coupling agent, fully stirred and dissolved evenly, that is, pre-emulsified Liquid I;

[0063] b) Polymerization I: Add 0.34 parts of reactive anionic emulsifier, 0.3 parts of reactive nonionic emulsifier...

Embodiment 2

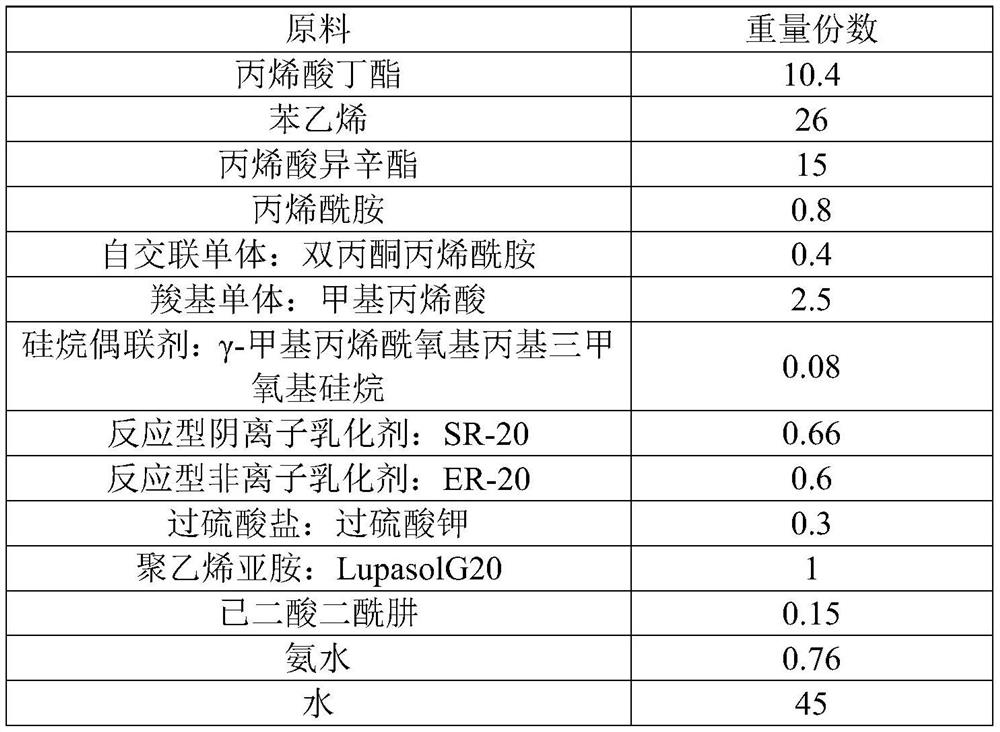

[0070] An acrylic ester emulsion for building interior wall paint is prepared by comprising the following raw materials in parts by weight:

[0071]

[0072] The preparation method of the acrylic ester emulsion for the above-mentioned architectural interior wall paint is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com