Straight-chain dialdehyde-modified polyvinyl alcohol and preparation method and application thereof

A technology of polyvinyl alcohol and dialdehyde, which is applied in the field of straight-chain dialdehyde modified polyvinyl alcohol and its preparation, can solve the problems of excessively wide molecular weight distribution, poor foam suppression performance, and high economic cost, and achieve the goal of inhibiting chlorine Foaming during ethylene polymerization, suppression of foaming, and short process time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

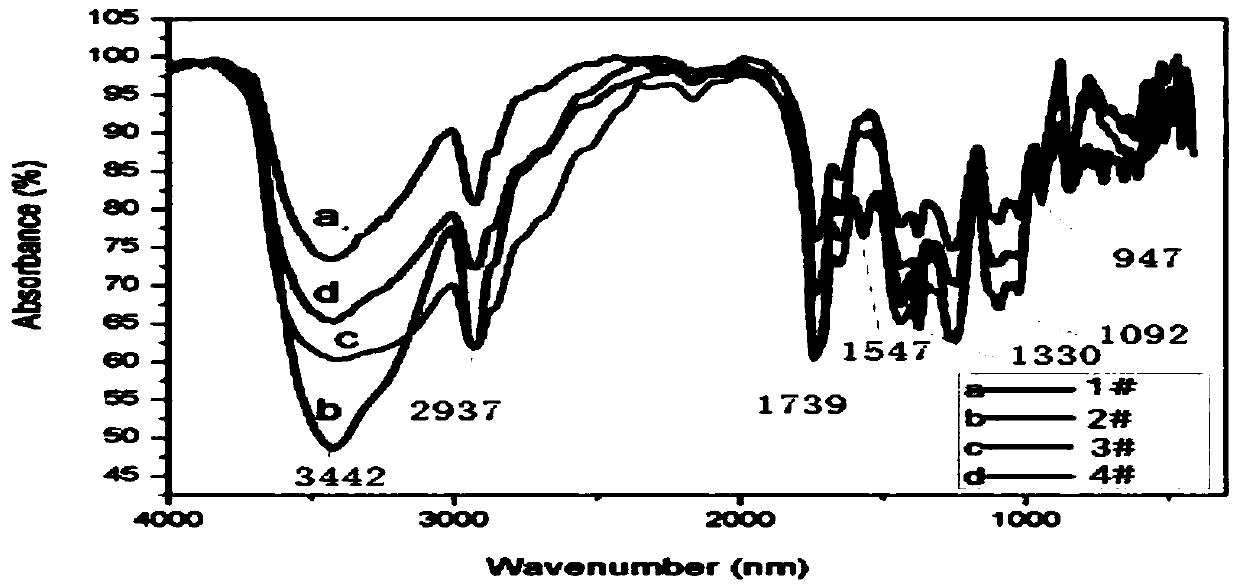

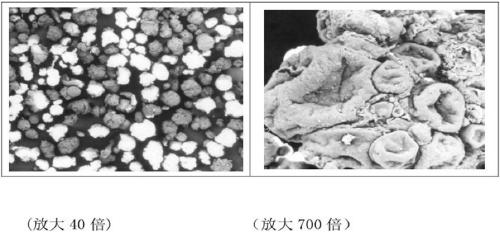

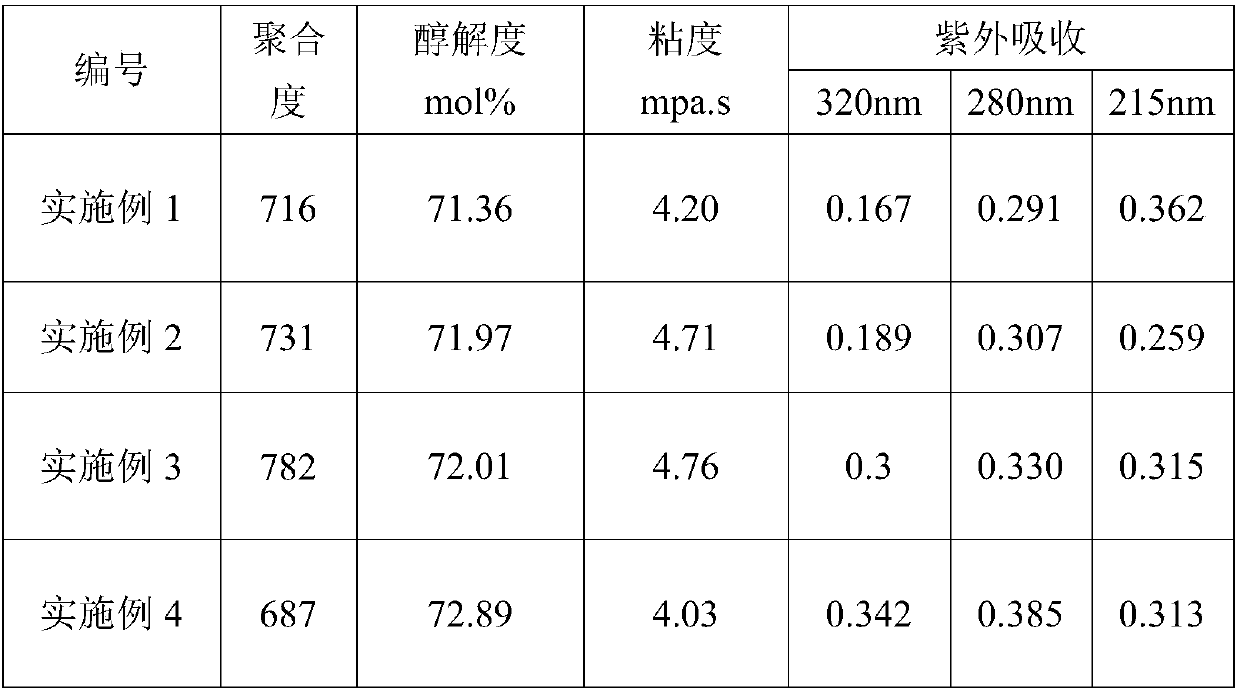

[0035]100 parts by weight of vinyl acetate, 100 parts by weight of methanol, 3.0 parts by weight of adipaldehyde and 0.072 parts by weight of azobisisobutyronitrile (AIBN) were added to the polymerization reactor. After replacing with nitrogen, the temperature began to rise, and the polymerization reaction began to count when there was reflux at about 60° C., and ended after 5 hours. Unreacted vinyl acetate is then removed to obtain a methanol solution of polyvinyl acetate. To the obtained polyvinyl acetate methanol solution (concentration 32-35%), add 10 millimoles of sodium hydroxide in methanol per mole of vinyl acetate unit. Carry out hydrolysis at 40°C for 35 minutes, add glacial acetic acid equivalent to sodium hydroxide to terminate the reaction, and obtain a methanol solution of PVA resin, and send the methanol solution of PVA resin evenly into a centrifuge protected by nitrogen through a screw pump for solidification Liquid separation, to obtain PVA resin (1# degree ...

Embodiment 2

[0037] 100 parts by weight of vinyl acetate, 80 parts by weight of methanol, 3.5 parts by weight of adipaldehyde and 0.072 parts by weight of azobisisobutyronitrile (AIBN) were added to the polymerization reactor. After replacing with nitrogen, the temperature began to rise, and the polymerization reaction began to count when there was reflux at about 60° C., and ended after 5 hours. Unreacted vinyl acetate is then removed to obtain a methanol solution of polyvinyl acetate. To the resulting polyvinyl acetate methanol solution (concentration 32-35%), add 10 millimoles of sodium hydroxide in methanol per mole of vinyl acetate unit. Hydrolyze at 40° C. for 35 minutes, add glacial acetic acid equivalent to sodium hydroxide to terminate the reaction, and obtain PVA resin (2# degree of polymerization 731, degree of alcoholysis 71.97 mol%) after centrifugation. The obtained PVA resin was dried in a vacuum drying oven at 110° C. for 2 hours under a vacuum degree of −0.01 MPa to obtai...

Embodiment 3

[0039] 100 parts by weight of vinyl acetate, 60 parts by weight of methanol, 4.5 parts by weight of adipaldehyde and 0.070 parts by weight of azobisisobutyronitrile (AIBN) were added to the polymerization reactor. After replacing with nitrogen, the temperature began to rise, and the polymerization reaction began to count when there was reflux at about 60° C., and ended after 5 hours. Unreacted vinyl acetate is then removed to obtain a methanol solution of polyvinyl acetate. To the resulting polyvinyl acetate methanol solution (concentration 32-35%), add 10 millimoles of sodium hydroxide in methanol per mole of vinyl acetate unit. Carry out hydrolysis at 40°C for 35 minutes, add glacial acetic acid equivalent to sodium hydroxide to terminate the reaction, and obtain a methanol solution of PVA resin, and send the methanol solution of PVA resin evenly into a centrifuge protected by nitrogen through a screw pump for solidification The liquid was separated to obtain PVA resin (3# ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com