High-strength permeable pavement brick and preparation method thereof

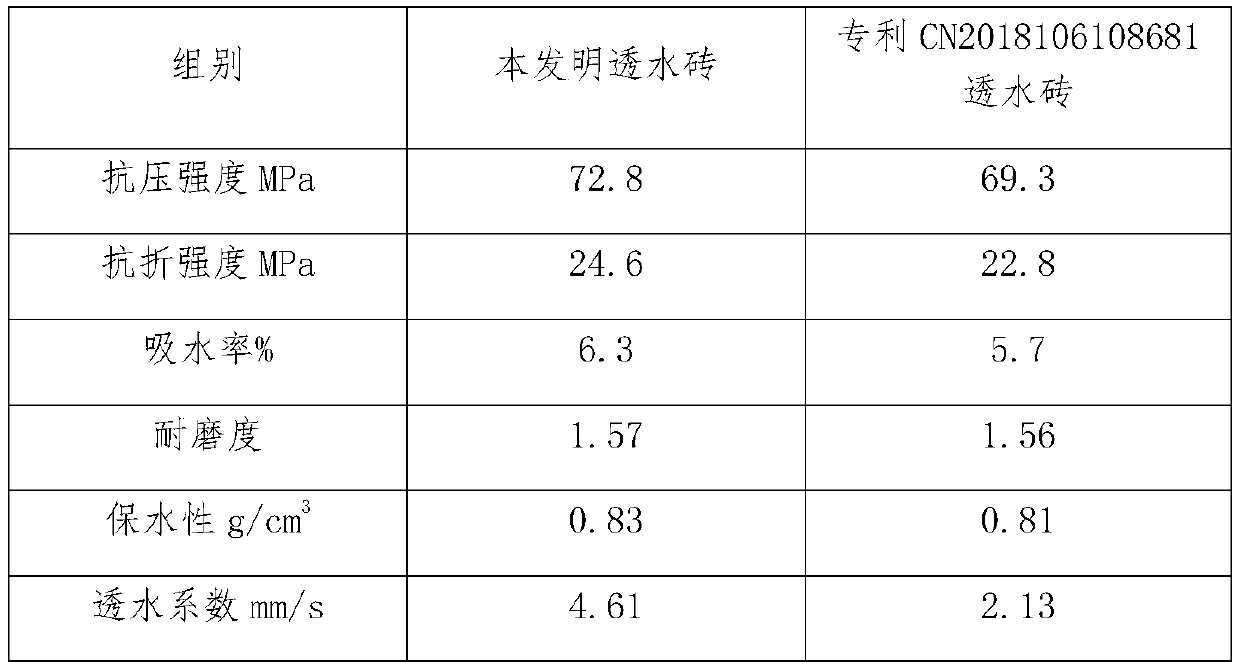

A permeable pavement brick, high-strength technology, applied in ceramic products, other household utensils, sustainable waste treatment, etc., can solve the problems of unsatisfactory strength of permeable pavement bricks, large amount of cement, and insufficient water permeability, etc., to reduce mining Even waste, water permeability improvement, effect of improving water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A high-strength permeable pavement brick, comprising the following raw materials in parts by weight: 25kg of waste concrete blocks, 15kg of gypsum powder, 5kg of river sand, 10kg of Portland cement, 5kg of sepiolite, 0.1kg of polycarboxylic acid, 0.1kg of organic silicon, Water reducer 1kg, modified additive 5kg, water 10kg.

[0030] The modified additive is formed by mixing cornstarch and wheat husk flour in an equal mass ratio.

[0031] The preparation method of the above-mentioned high-strength permeable pavement brick comprises the following steps:

[0032] (1) Take waste concrete blocks, gypsum powder, river sand, Portland cement, sepiolite, polycarboxylic acid, organic silicon, water reducing agent, modified additives, water according to the formula, and set aside;

[0033] (2) After mixing waste concrete blocks and sepiolite, crush them into particles with a particle size of ≤1 mm;

[0034] (3) Put the step (2) granules, gypsum powder, river sand, Portland ceme...

Embodiment 2

[0040] A high-strength permeable pavement brick, comprising the following raw materials in parts by weight: 35kg of waste concrete blocks, 25kg of gypsum powder, 10kg of river sand, 15kg of Portland cement, 10kg of sepiolite, 0.5kg of polycarboxylic acid, 0.5kg of organic silicon, Water reducer 2kg, modified additive 10kg, water 20kg.

[0041] The modified additive is prepared by mixing cornstarch and wheat husk flour in an equal mass ratio.

[0042] The corn starch is calcined at high temperature in vacuum, the calcining temperature is 220° C., and the calcining time is 6 hours.

[0043] Described wheat husk flour is processed in the following way:

[0044] (1) Put wheat husk powder into a stirring tank, add NaOH solution to soak for 45min, then heat to 75°C and stir for 2h, cool the particle suspension, filter out water, wash twice with deionized water, and then Drying under conditions until the water content in the wheat husk is <1%, to obtain pretreated wheat husk powder...

Embodiment 3

[0055] A high-strength permeable pavement brick, comprising the following raw materials in parts by weight: 25kg of waste concrete blocks, 25kg of gypsum powder, 5kg of river sand, 15kg of Portland cement, 10kg of sepiolite, 0.1kg of polycarboxylic acid, 0.5kg of organic silicon, Water reducer 1kg, modified additive 5kg, water 20kg.

[0056] The modified additive is prepared by mixing cornstarch and wheat husk flour in an equal mass ratio.

[0057] The cornstarch is calcined at high temperature in vacuum, the calcining temperature is 200° C., and the calcining time is 5 hours.

[0058] Described wheat husk flour is processed in the following way:

[0059] (1) Put wheat husk powder into a stirring tank, add NaOH solution to soak for 60min, then heat to 85°C and stir for 3h, cool the particle suspension, filter out water, wash with deionized water three times, and then Drying under conditions until the water content in the wheat husk is <1%, to obtain pretreated wheat husk pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com