Multifunctional concrete additive and preparation method thereof

A technology for concrete and additives, applied in the field of building materials, can solve the problems of poor maintenance effect, single function, high cost, etc., and achieve the effects of low preparation cost, excellent comprehensive performance and improved construction performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

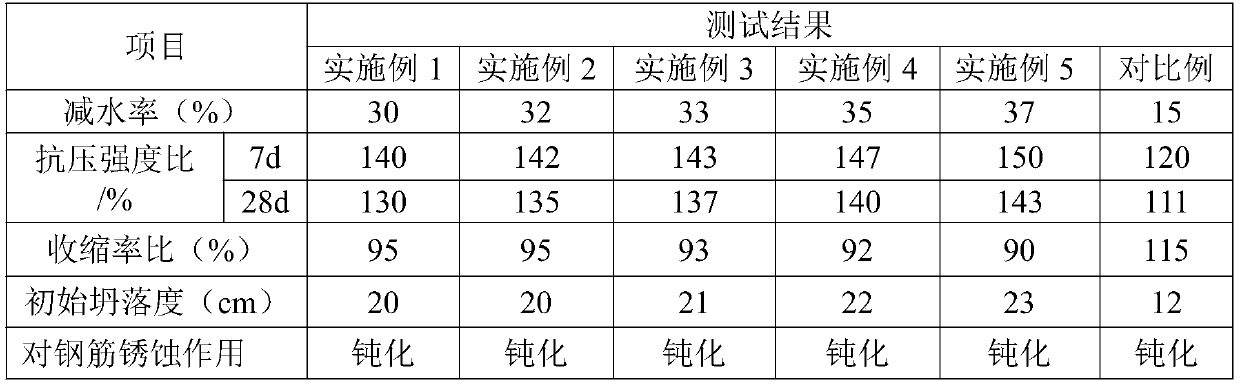

Examples

Embodiment 1

[0029] A multifunctional concrete additive, comprising the following components in parts by weight: 25 parts of polybazedoxifene di-beta-D-glucuronide 2,2'-bissulfonic acid benzidine amide, polyoxyethylene lauryl ether carboxylate 10 parts of acid-modified mono(6-polyethylene polyamine-6-deoxy) beta-cyclodextrin, 5 parts of active silica powder, 5 parts of ethanol, and 25 parts of water.

[0030] The preparation method of the polybazedoxifene di-beta-D-glucuronide 2,2'-disulfonic acid benzidine amide comprises the following steps:

[0031] Step S1: Dissolve 54.6 g of bazedoxifene di-beta-D-glucuronide in 200 g of N,N-dimethylformamide, then add 10 g of tert-butyldimethylsilyl chloride and 3 g of imidazole, Stir the reaction at 30°C for 10 hours, then remove N,N-dimethylformamide by rotary evaporation, wash the product with ethanol three times, and then remove ethanol by rotary evaporation to obtain an intermediate product;

[0032] Step S2: Dissolve 28.3g of the intermediate ...

Embodiment 2

[0037] A multifunctional concrete additive, comprising the following components in parts by weight: 27 parts of polybazedoxifene di-beta-D-glucuronide 2,2'-bissulfonic acid benzidine amide, polyoxyethylene lauryl ether carboxylate 11 parts of acid-modified mono(6-polyethylene polyamine-6-deoxy) beta-cyclodextrin, 6 parts of active silica powder, 6 parts of ethanol, and 28 parts of water.

[0038] The preparation method of the polybazedoxifene di-beta-D-glucuronide 2,2'-disulfonic acid benzidine amide comprises the following steps:

[0039] Step S1: Dissolve 54.6 g of bazedoxifene di-beta-D-glucuronide in 230 g of N,N-dimethylformamide, and then add 10 g of tert-butyldimethylsilyl chloride and 3.5 g of imidazole , stirring and reacting at 33°C for 10.5 hours, then rotary evaporating to remove N,N-dimethylformamide, washing the product with ethanol 4 times, and then rotary evaporating to remove ethanol to obtain an intermediate product;

[0040] Step S2: Dissolve 28.3g of the i...

Embodiment 3

[0045] A multifunctional concrete additive, comprising the following components in parts by weight: 30 parts of polybazedoxifene di-beta-D-glucuronide 2,2'-bissulfonic acid benzidine amide, polyoxyethylene lauryl ether carboxylate 13 parts of acid-modified mono(6-polyethylene polyamine-6-deoxy) beta-cyclodextrin, 7 parts of active silica powder, 8 parts of ethanol, and 30 parts of water.

[0046] The preparation method of the polybazedoxifene di-beta-D-glucuronide 2,2'-disulfonic acid benzidine amide comprises the following steps:

[0047] Step S1: Dissolve 54.6 g of bazedoxifene di-beta-D-glucuronide in 250 g of N,N-dimethylformamide, then add 10 g of tert-butyldimethylsilyl chloride and 4 g of imidazole, Stir the reaction at 35°C for 11 hours, then remove N,N-dimethylformamide by rotary evaporation, wash the product with ethanol 4 times, and remove ethanol by rotary evaporation to obtain an intermediate product;

[0048] Step S2: 28.3g of the intermediate product, 10g of 2,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com