Surface treatment method for superfine metal nickel powder

A metal nickel powder, surface treatment technology, applied in metal processing equipment, transportation and packaging, etc., can solve the problem of nickel powder oxidation temperature limitation, different oxidation degrees, high energy consumption, avoid different oxidation degrees, complete oxidation reaction, The effect of high oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

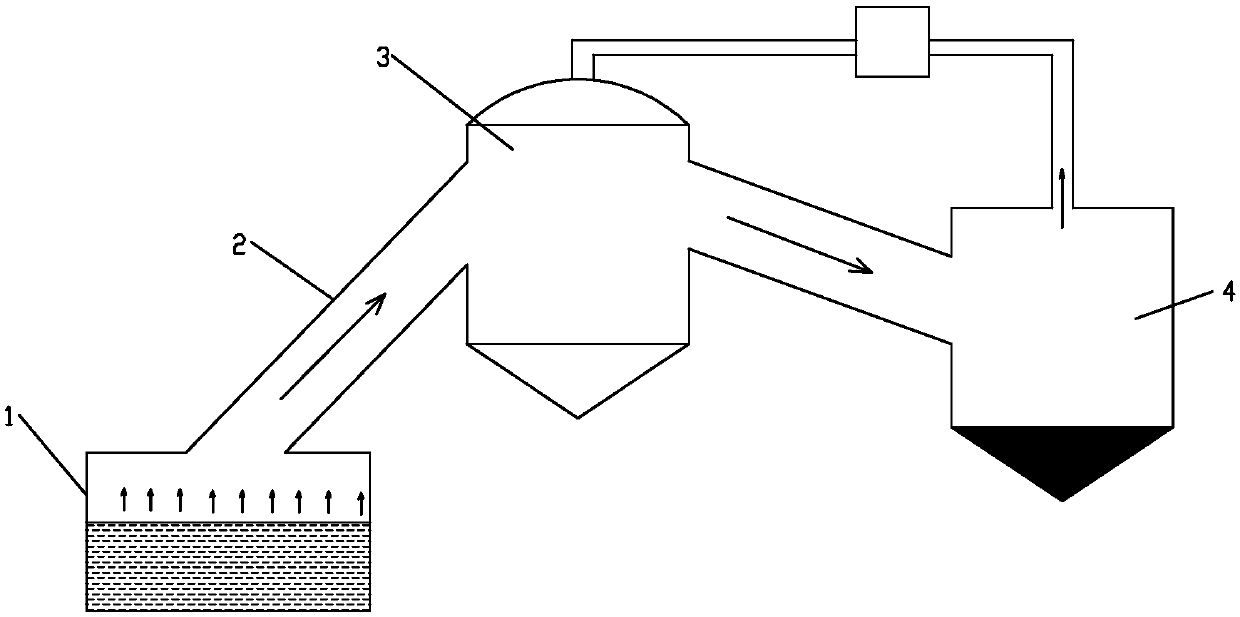

[0035] a. The spherical submicron metal nickel powder produced by PVD method, the nickel powder particle size is 0.05 μm, is added to the reactor 1 and heated to form a liquid state, and then heated and evaporated to form nickel vapor; at the same time, the reactor is filled with nitrogen; b. . Nickel vapor rises into the condenser pipe 2, and at the same time, the gas distributor in the condenser pipe 2 is opened to fill in nitrogen. The temperature of the nickel vapor coming out of the condenser pipe 2 is 300°C; c. Nickel powder particles enter the pulse from the condenser pipe 2. Cooling chamber 3, the flow channel cross-sectional area of the pulse cooling chamber 3 is 3 times the cross-sectional area of the outlet of the condensation pipe 2, and the gas distributor in the pulse cooling chamber 3 is filled with air to make the oxygen content volume in the pulse cooling chamber 3 The concentration is 0.3%; the temperature inside the pulse cooling chamber 3 is 300°C, the n...

Embodiment 2

[0037] The spherical submicron metal nickel powder produced by PVD method, the nickel powder particle size is 5 μm, is added to the reactor 1 and heated to form a liquid state, and then heated and evaporated to form nickel vapor; at the same time, the reactor is filled with nitrogen; b, nickel vapor Rise into the condensation pipe 2, and at the same time open the gas distributor in the condensation pipe 2 to fill in the air, the temperature of the nickel vapor from the outlet of the condensation pipe 2 is 500 °C; c, the nickel powder particles enter the pulse cooling chamber 3 from the condensation pipe 2 , the flow channel cross-sectional area of the pulse cooling chamber 3 is 5 times of the cross-sectional area of the condensation pipe 2 outlets, and the gas distributor in the pulse cooling chamber 3 is filled with air, so that the oxygen content volume concentration in the pulse cooling chamber 3 is 0.3 %; The temperature in the pulse cooling chamber 3 is 500°C, the nick...

Embodiment 3

[0039] The spherical submicron metal nickel powder produced by the PVD method, the nickel powder particle size is 3 μm, is added to the reactor 1 and heated to form a liquid state, and then heated and evaporated to form nickel vapor; at the same time, the reactor is filled with nitrogen; b. Nickel vapor Rise into the condensation pipe 2, and at the same time open the gas distributor in the condensation pipe 2 to fill in the air, the temperature of the nickel vapor from the outlet of the condensation pipe 2 is 420 °C; c, the nickel powder particles enter the pulse cooling chamber 3 from the condensation pipe 2 , the flow path cross-sectional area of the pulse cooling chamber 3 is 4 times of the cross-sectional area of the condenser tube 2 outlets, and the gas distributor in the pulse cooling chamber 3 is filled with air so that the oxygen content volume concentration in the pulse cooling chamber 3 is 0.3 %; The temperature in the pulse cooling chamber 3 is 450° C., the nicke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com