Aluminium film stamping shell forming system

A technology of aluminum film and forming device, which is applied in the field of aluminum film punching and forming, which can solve problems such as parallelism error, curling, uneven stretching of the punching shell, etc., to improve quality and speed, fast punching and forming, and material loss little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

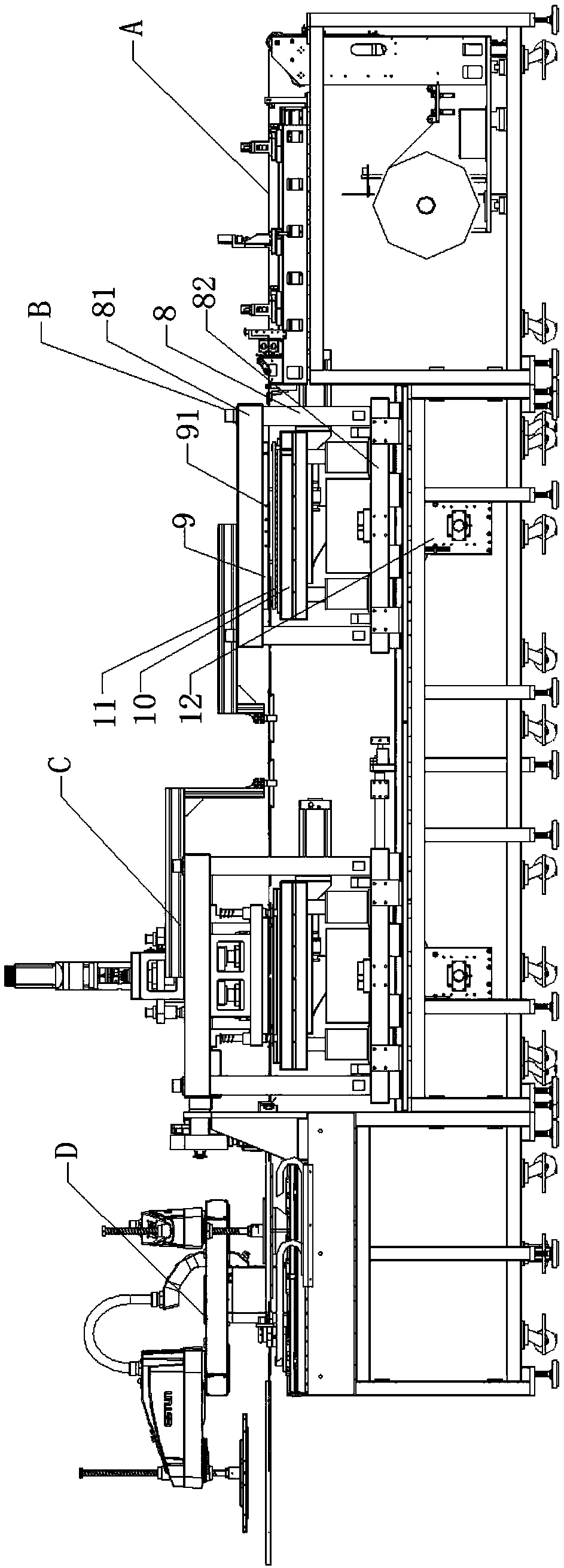

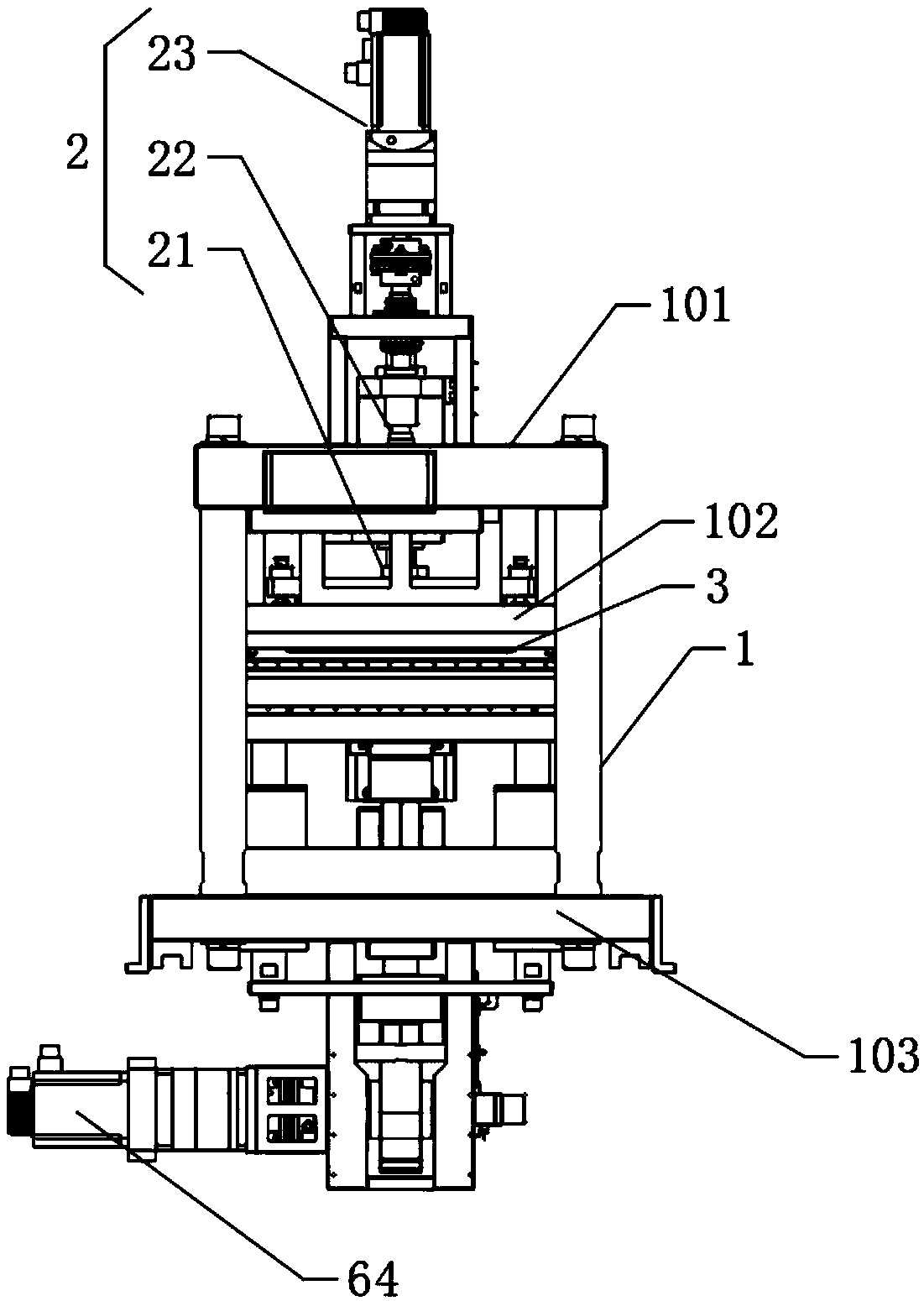

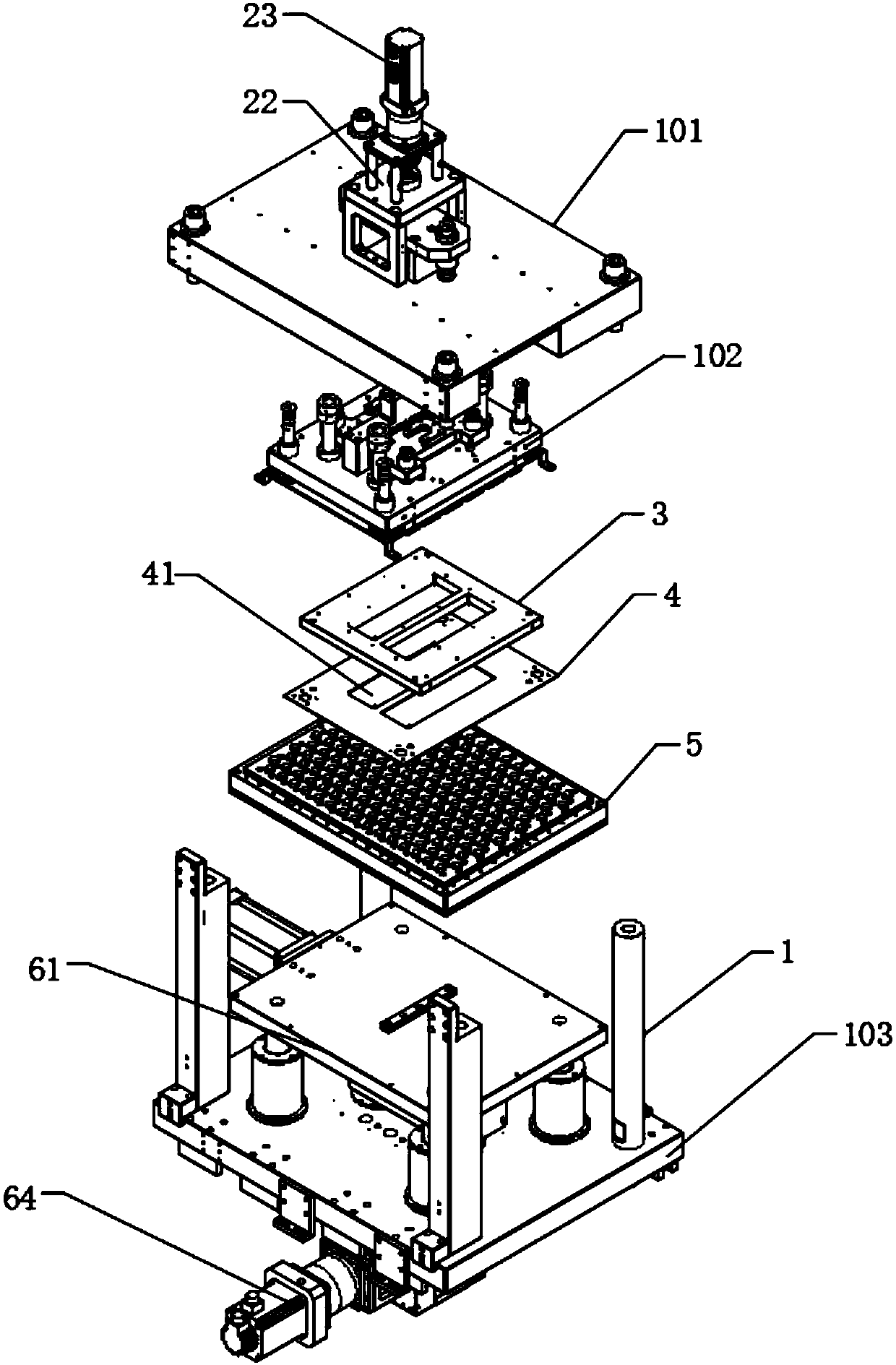

[0026] Such as Figure 1-3 As shown, this embodiment relates to an aluminum film punching and forming system, including a feeding device A, a pre-shelling device B, a punching and forming device C, and a blanking device D arranged sequentially along the conveying direction of the aluminum film; The shell molding device C includes a first stamping mechanism 2, a first upper platen 3, a first pressure regulating mechanism, and a first lifting mechanism 6 for jacking up the first pressure regulating mechanism arranged in sequence from top to bottom, and the first pressure regulating mechanism The mechanism includes the first concave template 4 and the first elastic adjustment mechanism 5 arranged in sequence from top to bottom. The first elastic adjustment mechanism 5 has multiple elastic output points. During the process of pressing the aluminum film, the first The concave formwork 4 cooperates with the first upper pressing plate 3 to compress the aluminum film, and the elastic ...

Embodiment 2

[0046] Such as Image 6 As shown, the difference between this embodiment and Embodiment 1 is that: in this embodiment, the first pressure adjustment mechanism also includes a first bottom plate arranged between the first concave plate 4 and the first elastic adjustment mechanism 5 Pressing plate 7 , the bottom surface of the first lower pressing plate 7 is provided with a plurality of positioning grooves for positioning the output rod 52 .

[0047] In the present embodiment, the first concave template 4 is made of stainless steel. In order to make the first concave template 4 have a certain deformability, the thickness of the first concave template 4 is less, only 3-8mm, which causes the aluminum film to punch pits. The depth is only limited. When it is necessary to deepen the punching depth of the aluminum film, the first lower pressing plate 7 needs to be added. The shape of the first lower pressing plate 7 is similar to that of the first concave template 4, and a third punc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com