Plant nutrient granulator using piston gas jet to prevent wall-sticking

An anti-sticking wall and granulator technology, which is applied in the direction of granulation in static tanks/slots, can solve the problems of reduced granulation efficiency, inability to drop, easy to breed bacteria, etc., and achieve the effect of preventing mutual adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

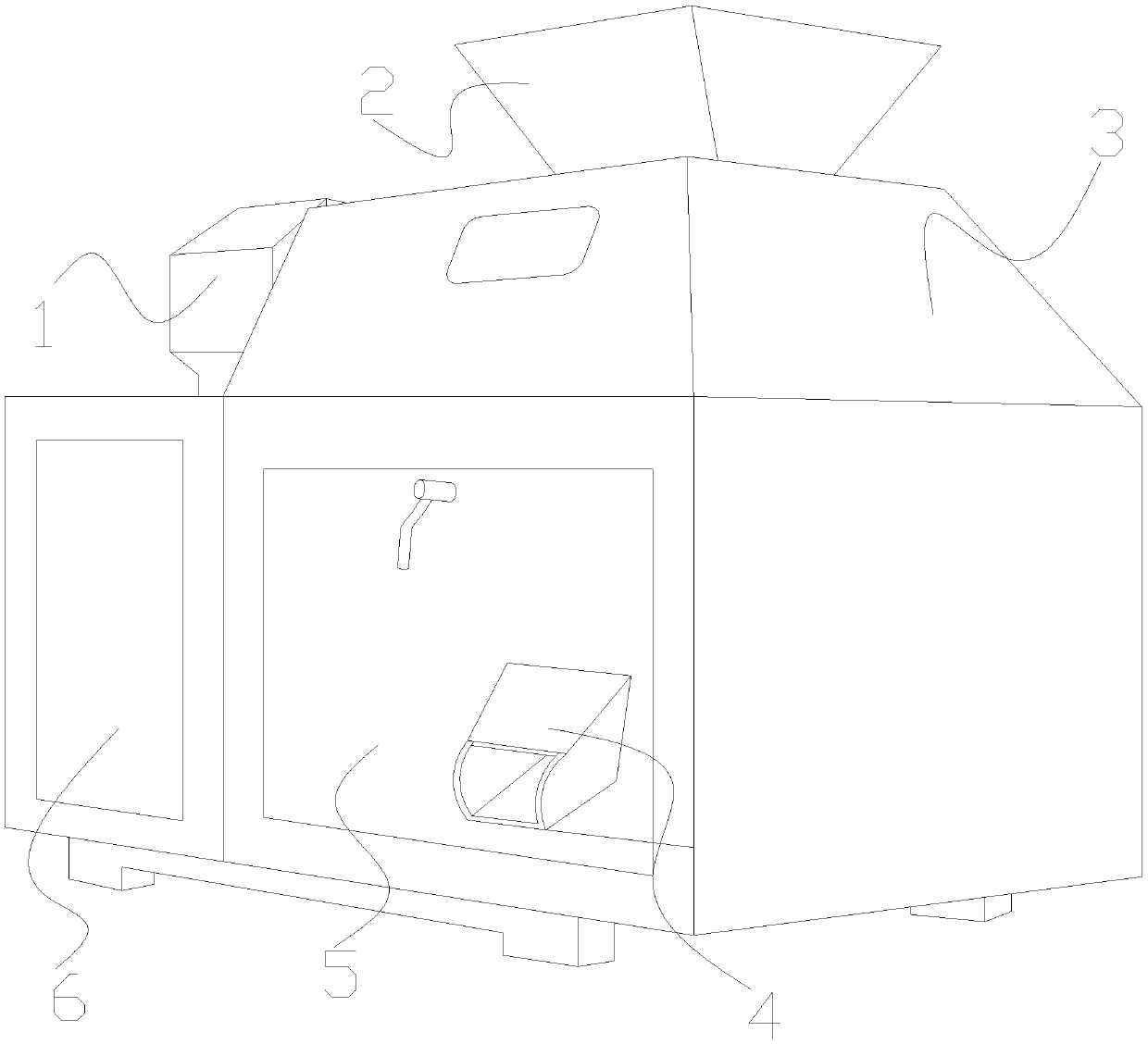

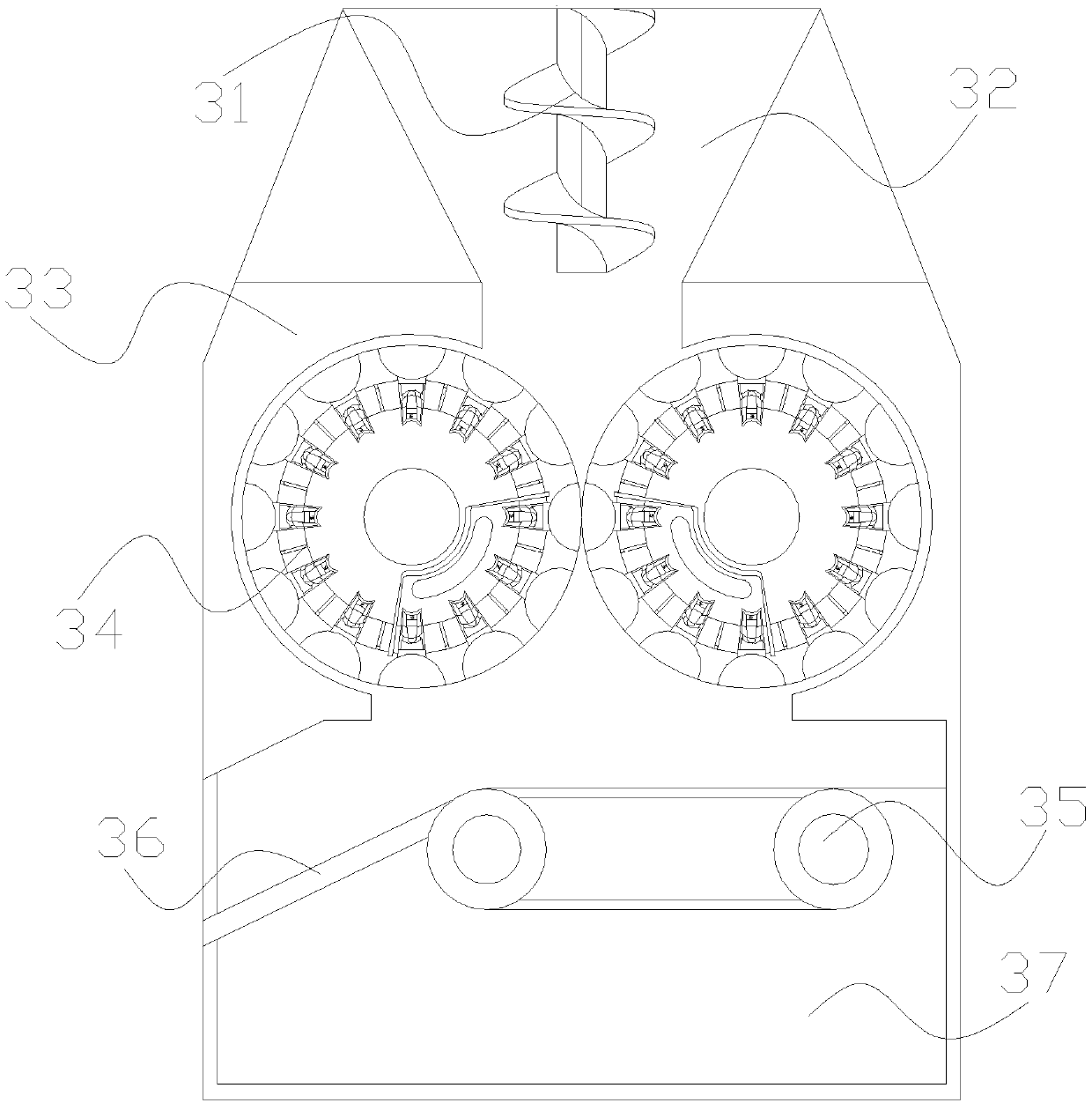

[0028] Such as Figure 1-6 As shown in the figure, the present invention provides a technical scheme of a plant nutrient granulator utilizing piston air spraying anti-sticking wall:

[0029] Such as Figure 1-3 As shown, a plant nutrient granulator using piston air spraying anti-sticking wall, its structure includes a driving device 1, a feed hopper 2, an anti-sticking wall granulating device 3, a discharge port 4, a maintenance door 5, and a control cabinet 6. The driving device 1 is installed above the control cabinet 6 and connected by bonding, the feeding hopper 2 is connected with the anti-sticking wall granulation device 3 by welding, and the discharge port 4 is embedded Installed on the front surface of the maintenance door 5, the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com