Metal particle modified graphene flexible sensor and preparation method and application thereof

A flexible sensor and metal particle technology, applied in the field of sensor and its preparation and application, can solve the problems of single function, low sensitivity and poor repeatability of the flexible sensor, and achieve the effect of increasing conductive path, large specific surface area and improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Disperse the platinum particle-modified graphene composite material into deionized water (1mg / mL), and ultrasonically disperse it for 0.5h; liquid, squeeze the sponge several times so that the dispersion liquid is filled into the sponge), fill the above composite material into the PDMS sponge (cutting size: length × width × height = 2cm × 2cm × 1mm); freeze-dry to obtain Platinum particle-modified graphene composite loaded PDMS conductive sponge. Repeat the above steps several times to obtain conductive sponges with different weight ratios of graphene composite materials.

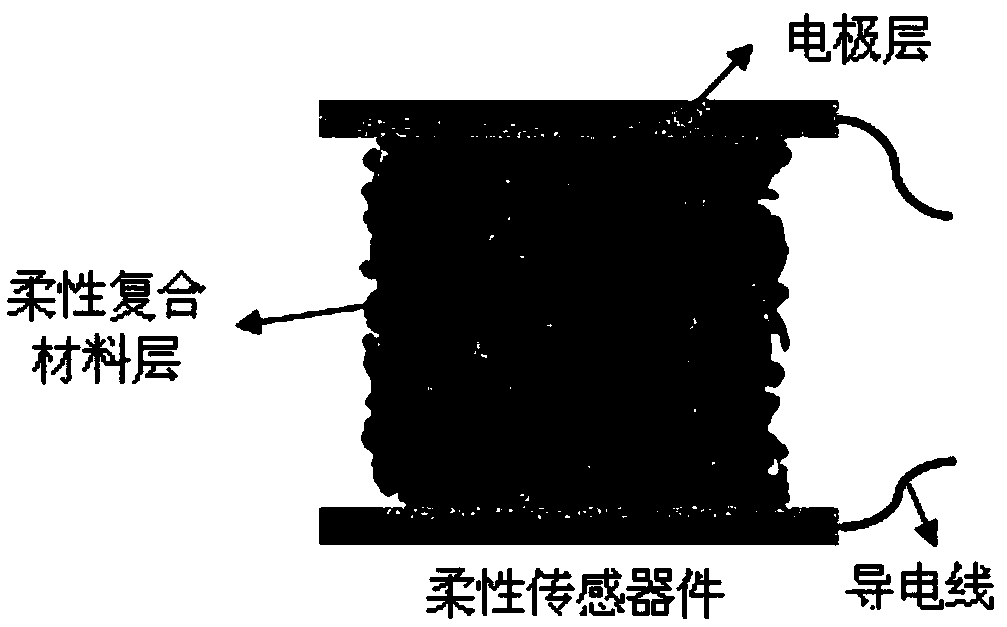

[0049] (2) Take two pieces of indium tin oxide conductive glass (thickness is 1mm), use two sections of conductive copper wire to connect with two pieces of indium tin oxide conductive glass respectively to prepare conductive electrodes; then paste the prepared conductive electrodes on The upper and lower surfaces of the above-mentioned conductive sponge are prepared into flexible sensor devices...

Embodiment 2

[0053] (1) Disperse the graphene composite material modified by palladium particles in deionized water (3mg / mL), and disperse ultrasonically for 0.5h; liquid, squeeze the sponge repeatedly so that the dispersion liquid is filled into the sponge) fill the above-mentioned composite material into the polyurethane sponge (cutting size: length × width × height = 2cm × 2cm × 0.5cm); freeze-dry to obtain Polyurethane conductive sponge supported by palladium particle-modified graphene composite. Repeat the above steps once and four times to obtain conductive sponges with graphene-containing composite materials accounting for 0.5 wt% and 2.7 wt% respectively.

[0054] (2) Take two pieces of indium tin oxide conductive glass (thickness is 1mm), use two sections of conductive copper wire to connect with two pieces of indium tin oxide conductive glass respectively to prepare conductive electrodes; then paste the prepared conductive electrodes on The left and right sides of the conductive...

Embodiment 3

[0057] (1) Disperse the silver particle-modified graphene composite material into deionized water (3mg / mL), and ultrasonically disperse for 0.5h; liquid, squeeze the sponge several times so that the dispersion liquid is filled into the sponge) fill the above composite material into the PDMS sponge (cutting size: length × width × height = 1cm × 2cm × 1cm); freeze-dry to obtain silver Particle-modified graphene composite supported PDMS conductive sponge. Repeat the above steps several times to obtain conductive sponges with different weight ratios of graphene composite materials.

[0058] (2) Take two pieces of indium tin oxide conductive glass (thickness is 1mm), use two sections of conductive copper wire to connect with two pieces of indium tin oxide conductive glass respectively to prepare conductive electrodes, paste them on the upper and lower surfaces of the conductive sponge, and prepare a flexible gas sensors (such as figure 1 ).

[0059] Wherein, the preparation met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com