Three-dimensional pressure sensor based on flexible tactile capacitor

A three-dimensional pressure and sensor technology, applied in the field of sensors, can solve the problems of lack of three-dimensional pressure sensors, difficult to wear and integrate, large size, etc., to achieve the effect of multi-point high-precision measurement, integration and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

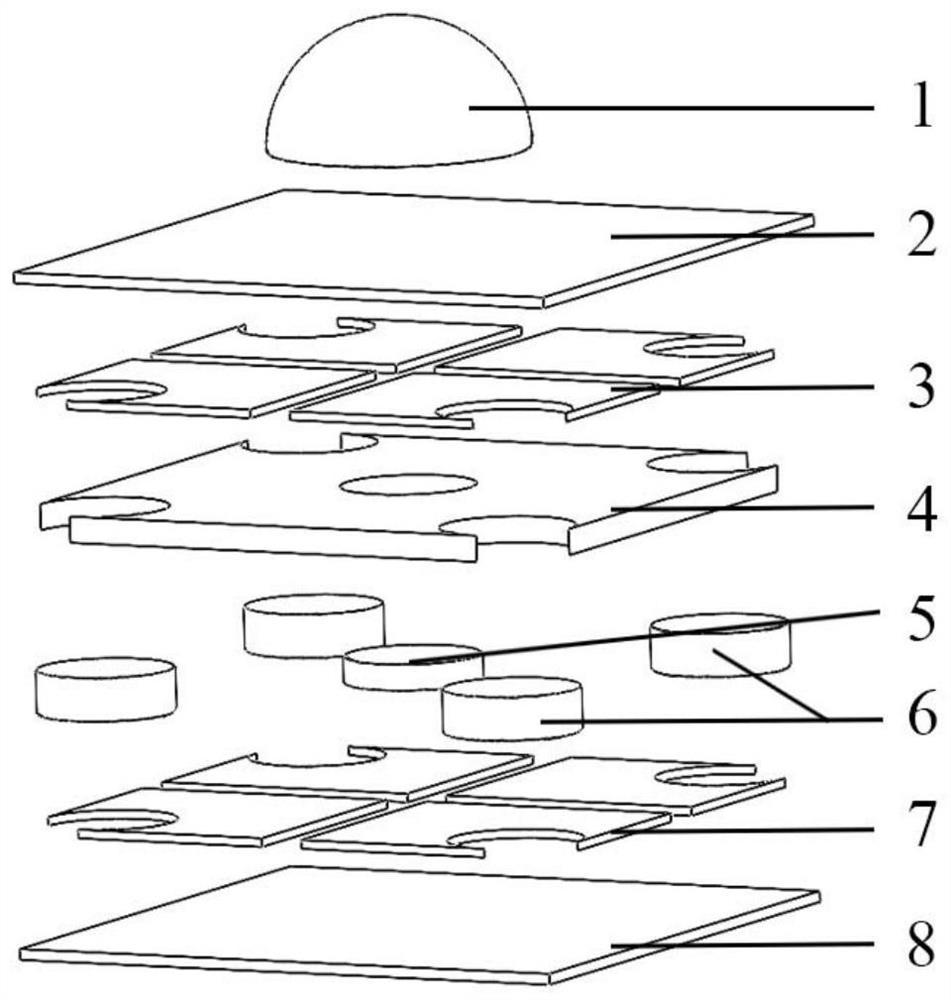

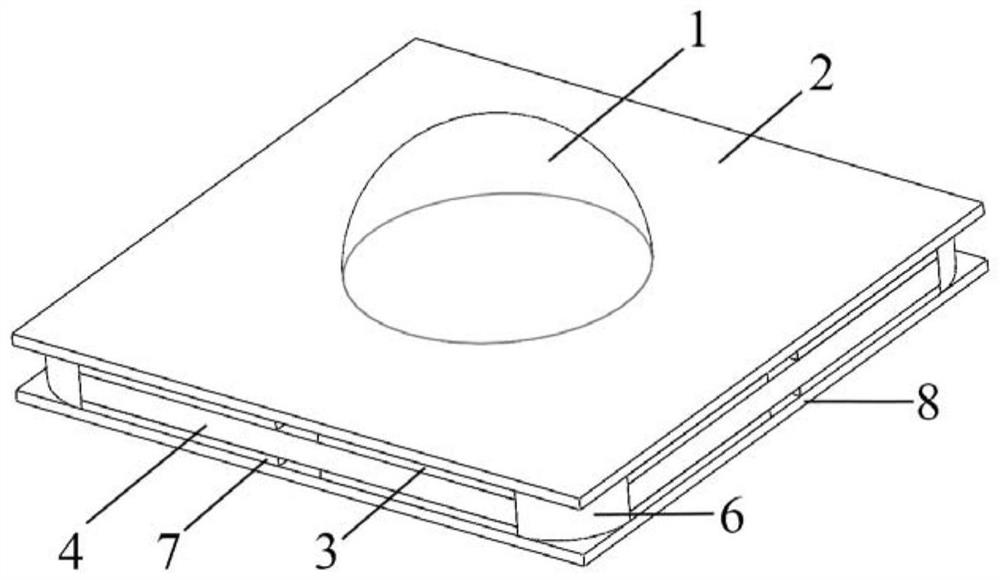

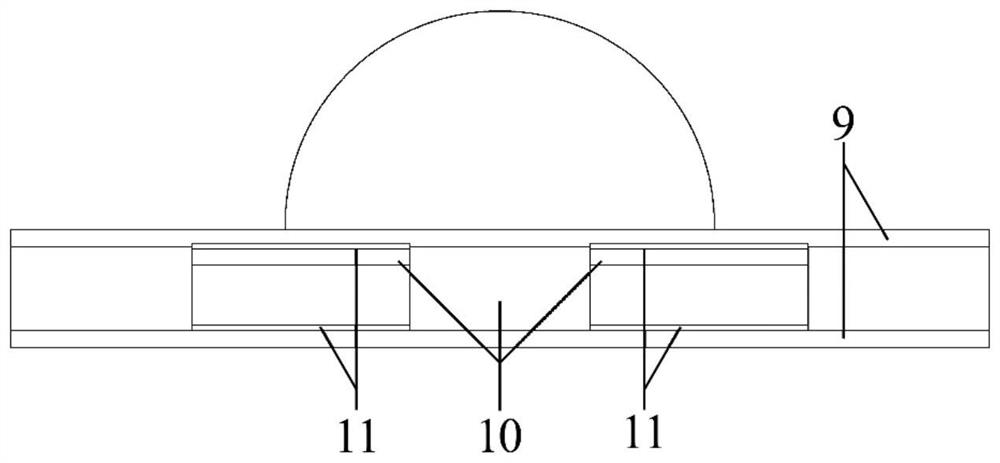

[0043] Such as Figure 1-Figure 3As shown, the three-dimensional pressure sensor based on the flexible tactile capacitance of the present invention proposes a six-layer mutual capacity flexible tactile sensor structure, that is, the main body capacitance sensing part of the sensor includes six main layers of main structures: spherical contact terminal 1, capacitor Upper electrode layer 3 , inter-electrode dielectric layer 4 , tough support cylinder 5 , capacitor lower electrode layer 7 , flexible upper base layer 2 , and flexible lower base layer 8 . In each tactile sensor unit, the capacitor upper electrode layer 3, the capacitor lower electrode layer 7 and the inter-electrode dielectric layer 4 form four differential capacitors at symmetrical positions, and are supported by the flexible support pad 5 and the flexible support cylinder 6. It constitutes the basic unit for monitoring three-dimensional force. The center of the spherical contact end is located directly above the...

Embodiment 2

[0062] Such as figure 2 A three-dimensional pressure sensor shown has the following structural parameters: the diameter of the bottom surface of the spherical contact tip is 2500 μm, the height is 300 μm, and the flexible upper and lower substrate layers are polydimethylsiloxane (PDMS) with a length of 5400 μm, a width of 5400 μm, and a thickness of 200 μm. ) layer, the four short sides of the upper electrode layer of the capacitor are 1500 μm long, the two long sides are 2500 μm long, and the thickness is 10 μm; The support cylinder is 20 μm in diameter and 30 μm high, and the ductile support spacer is 20 μm in diameter and 30 μm high. According to theoretical calculation, the sensor can support 0-10N force sensing. In a specific embodiment, the VERNIER data collector labquest-mini is used to place on the linmot linear motor to change the pressure by controlling the amount of travel of the linear motor, that is, to apply a standard force to the sensor; at the same time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com