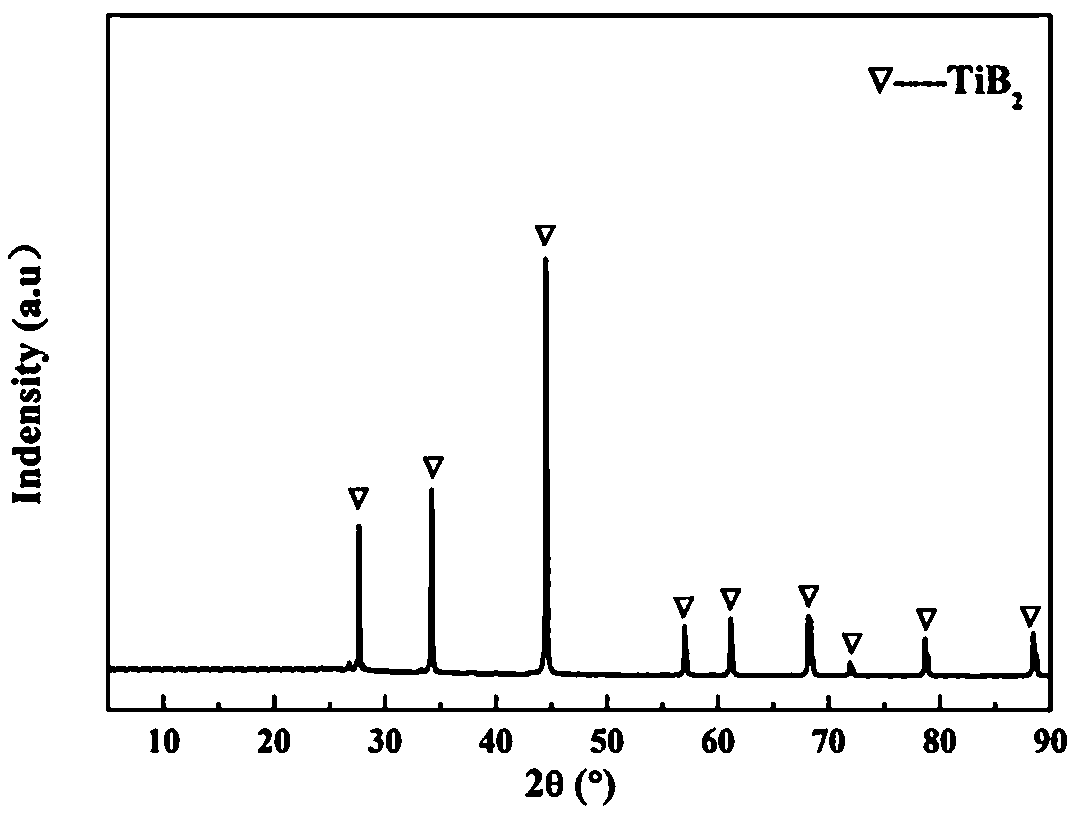

Preparation method of high-temperature oxidation-resistant TiB2 whiskers with high melting point

A high-temperature oxidation-resistant, high-melting point technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as difficult to obtain high-density whisker products, and can not strictly control the reaction process and product performance, to achieve the formation of The effect of clear mechanism, multiple choices of molten salt system, high migration rate and diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of a kind of anti-high temperature oxidation high melting point TiB whisker disclosed in this embodiment comprises the following steps:

[0035] S1, take TiB2 and KCl of the process proportioning number, wherein the molar ratio of TiB2 and KCl is 1:1, mix the TiB2 and KCl after weighing into the grinding machine, add a small amount of dehydrated alcohol simultaneously, without The amount of water alcohol added is adjusted according to the total amount of processing. The purpose is to achieve a better grinding effect. Usually, it is preferred to use 1 / 10 of the total amount of anhydrous alcohol. The total amount of anhydrous alcohol can be based on the liquid index of the reaction raw materials The ratio is obtained by corresponding calculation. To be ground into powder particles, which are in the state of powder particles of 70 mesh to 100 mesh, add the remaining anhydrous alcohol and stir evenly to obtain thick reaction raw materials. The liquid i...

Embodiment 2

[0041] The preparation method of a kind of anti-high temperature oxidation high melting point TiB whisker disclosed in this embodiment comprises the following steps:

[0042]S1. Weigh TiB2 and molten salt in the proportion of the process. The molten salt is a mixed powder of ZnSO4 7H2O and Na2CO3, wherein the molar ratio of TiB2 and molten salt is 1:1, and ZnSO4 7H2O and Na2CO3 in the molten salt system The molar ratio is 1:1.2. Mix the weighed TiB2 and molten salt into a grinder for grinding, and add a small amount of absolute alcohol at the same time. The amount of absolute alcohol added is adjusted according to the total amount of processing. The purpose is to achieve For a better grinding effect, it is usually preferred to use 1 / 10 of the total amount of anhydrous alcohol. The total amount of anhydrous alcohol can be obtained by corresponding calculation based on the liquid index ratio in the reaction raw materials. To be ground into powder particles, it is at 70 mesh~ In ...

Embodiment 3

[0048] The preparation method of a kind of anti-high temperature oxidation high melting point TiB whisker disclosed in this embodiment comprises the following steps:

[0049] S1, take by weighing TiB2 and molten salt of process proportioning number, molten salt selects Na2SO4, KCl mixed powder, wherein the molar ratio of TiB2 and molten salt is 1:0.8, wherein in the molten salt system Na2SO4 and the molar ratio of KCl are 1.5:1, mix the weighed TiB2 and molten salt into a grinder for grinding, and add a small amount of absolute alcohol at the same time, the amount of absolute alcohol added is adjusted according to the total amount of processing, the purpose is to achieve better grinding Effect, usually preferably 1 / 10 of the total amount of anhydrous alcohol, the total amount of anhydrous alcohol can be obtained by corresponding calculation based on the liquid index rate of the reaction raw materials, to be ground into powder particles, in the form of 70 mesh to 100 mesh powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com