RH refining method of low-carbon stainless steel

A stainless steel refining technology, applied in RH hydrogen blowing refining of low-carbon high-alumina stainless steel, RH hydrogen blowing refining of low-carbon stainless steel, to reduce quantity and particle size, improve product quality, and reduce alumina inclusions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

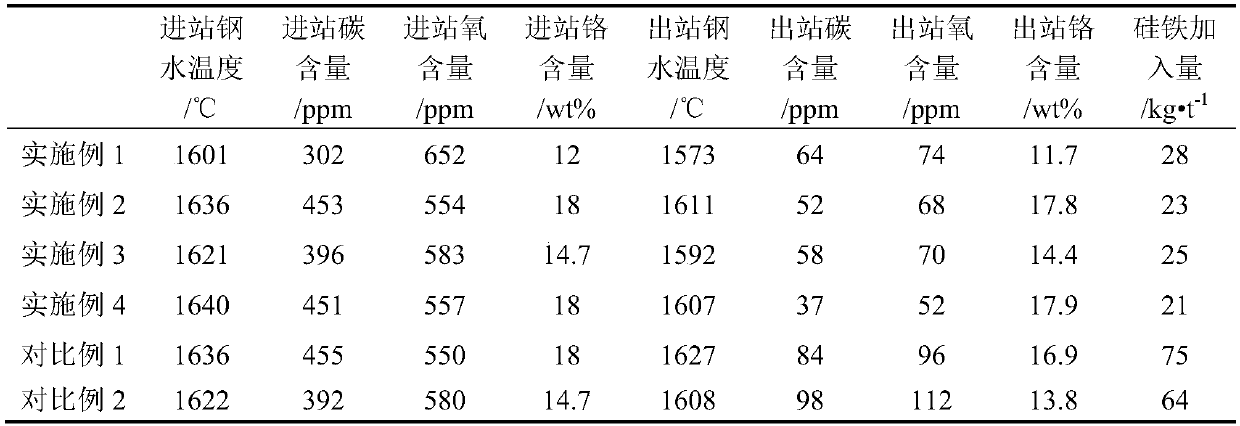

Embodiment 1

[0044] A kind of RH refining method of low-carbon stainless steel, mainly comprises the following steps:

[0045] (1) Argon nozzles and hydrogen nozzles are arranged on the riser of the RH dipping tube, and a top blowing oxygen lance is arranged in the vacuum chamber;

[0046] (2) Hoist the ladle with molten steel to the RH workstation. The carbon content of the molten steel is 302ppm, the oxygen content is 652ppm, and the chromium content is 12%. After temperature measurement and oxygen determination, the temperature of the molten steel entering the RH station is controlled at 1601°C, and then the vacuum pump is started. Vacuum to 8kPa, blow argon at the same time to circulate the molten steel for 5 minutes, and control the flow rate of the lifting gas at 150m 3 / h;

[0047] (3) Turn on the multi-stage vacuum pump to evacuate to 1kPa, blow oxygen with the oxygen reducing gun, and control the oxygen flow at 1500Nm 3 / h, the total amount of oxygen blowing is controlled at 600...

Embodiment 2

[0053] A kind of RH refining method of low-carbon stainless steel, mainly comprises the following steps:

[0054] (1) Argon nozzles and hydrogen nozzles are arranged on the riser of the RH dipping tube, and a top blowing oxygen lance is arranged in the vacuum chamber;

[0055] (2) Hoist the ladle with molten steel to the RH workstation. The carbon content of the molten steel is 453ppm, the oxygen content is 554ppm, and the chromium content is 18%. After temperature measurement and oxygen determination, the temperature of the molten steel entering the RH station is controlled at 1636°C, and then the vacuum pump is started. Vacuum to 10kPa, blow argon at the same time to circulate the molten steel for 3 minutes, and control the flow rate of the lifting gas at 180m 3 / h;

[0056] (3) Turn on the multi-stage vacuum pump to evacuate to 0.8kPa, blow oxygen with the oxygen-reducing lance, and control the oxygen flow at 2000Nm 3 / h, the total amount of oxygen blowing is controlled a...

Embodiment 3

[0062] A kind of RH refining method of low-carbon stainless steel, mainly comprises the following steps:

[0063] (1) Argon nozzles and hydrogen nozzles are arranged on the riser of the RH dipping tube, and a top blowing oxygen lance is arranged in the vacuum chamber;

[0064] (2) Hoist the ladle with molten steel to the RH workstation. The carbon content of the molten steel is 396ppm, the oxygen content is 583ppm, and the chromium content is 14.7%. After temperature measurement and oxygen determination, the temperature of the molten steel entering the RH station is controlled at 1621°C, and then the vacuum pump is started. Vacuum to 9kPa, blow argon at the same time to circulate the molten steel for 4 minutes, and control the flow rate of the lifting gas at 150-220m 3 / h;

[0065] (3) Turn on the multi-stage vacuum pump to evacuate to 0.9kPa, blow oxygen with the oxygen-reducing lance, and control the oxygen flow at 1800Nm 3 / h, the total amount of oxygen blowing is control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com