Leaching machine

A technology of leaching and reducer, which is applied in the field of extraction, can solve the problems of easy detachment of chain transmission, chain pins falling off, unavoidable contact, etc., and achieve the effect of simplified transmission, stable operation and elimination of potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

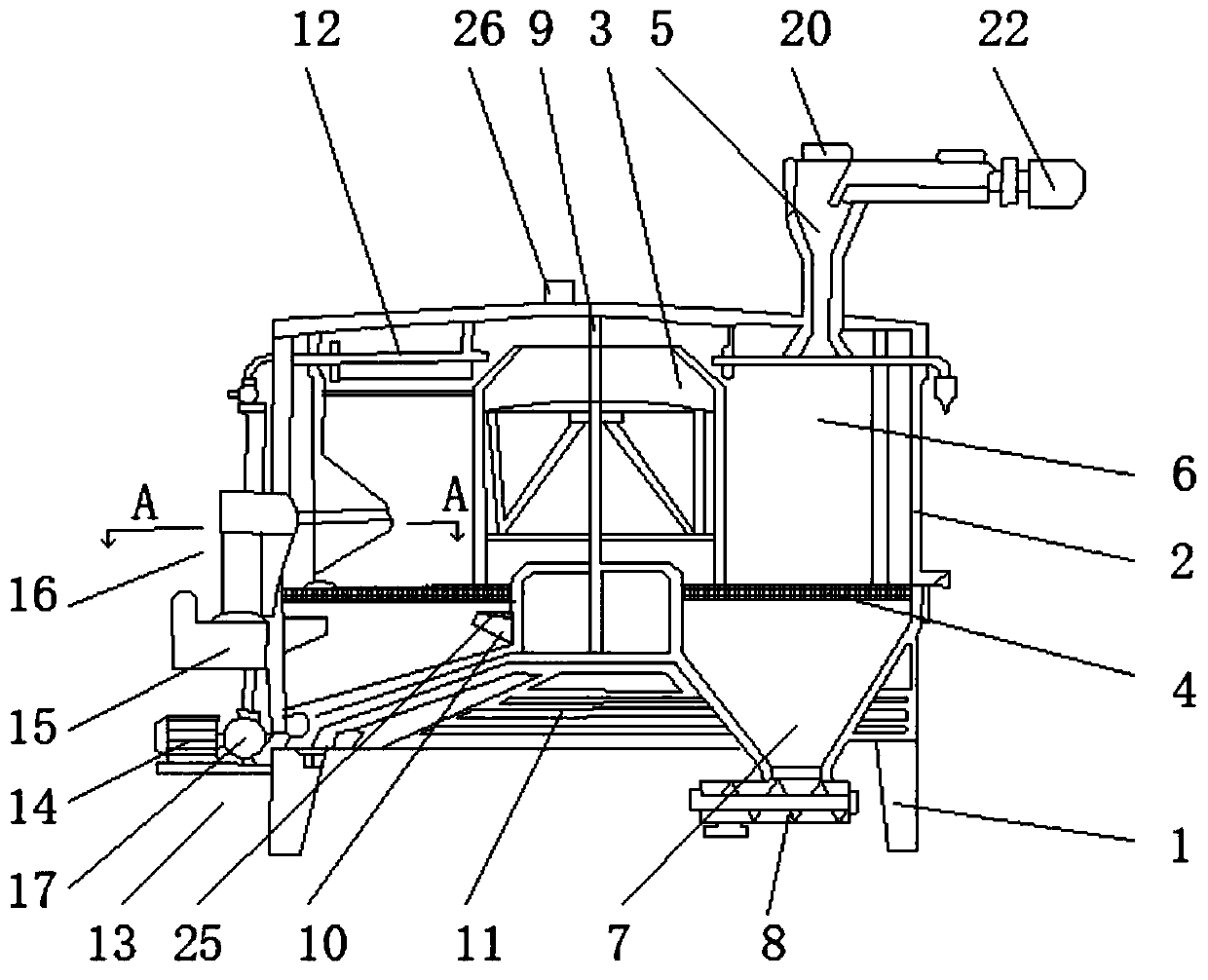

[0025] Such as Figure 1-3 As shown, a leaching machine includes a base 1, a housing 2, and a reaction chamber 3. A housing 2 is fixedly installed on the base 1. A reaction chamber 3 is arranged at the upper end of the housing 2 near the middle, and a horizontal chamber 3 is arranged below the reaction chamber 3. There is a fixed grid bottom 4, the two ends of the fixed grid bottom 4 are fixedly connected on the inner wall of the housing 2, the upper end of the housing 2 is provided with a feed port 5 near one side, and the lower end of the feed port 5 is connected with a rotating body 6, The rotating body 6 is located above the fixed grid bottom 4, the lower end of the rotating body 6 is connected with a meal output box 7, and the lower end of the meal output box 7 is connected with a meal output screw conveyor 8, and the middle of the reaction chamber 3 is vertically provided with a rotating shaft 9, The lower end of the reaction chamber 3 is connected with an oil outlet 10,...

Embodiment 2

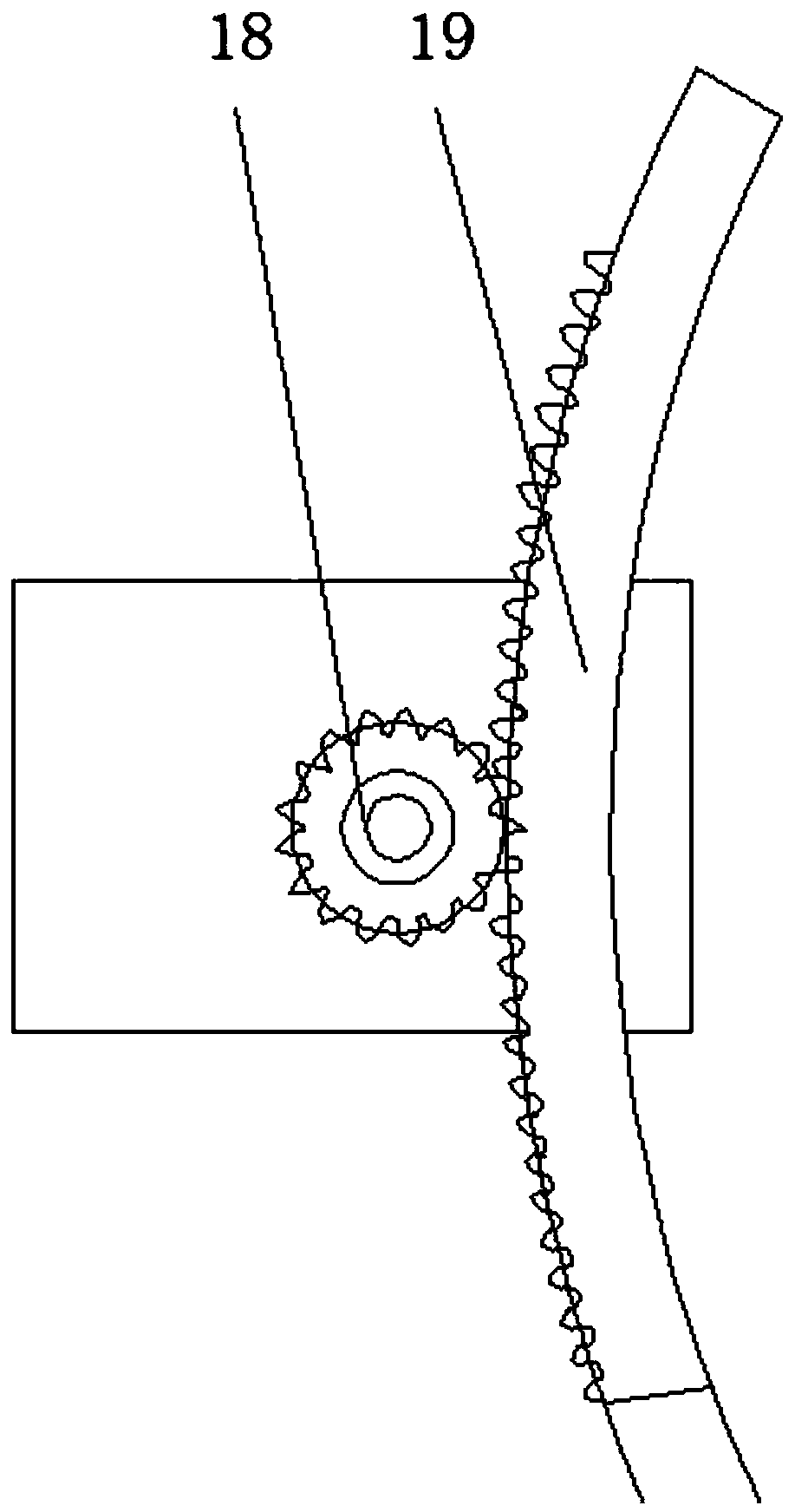

[0030] Such as Figure 1-3 As shown, a leaching machine, the transmission device 13 includes a motor 14, a reducer 15 and a transmission gear set 16, the output end of the motor 14 is connected with the input end of the reducer 15 through a mixing oil pump 17, and the output end of the reducer 15 is connected to the transmission The gear set 16 is connected, the transmission gear set 16 includes a driving pinion 18 and a driven bull gear 19, the output end of the reducer 15 is connected with the driving pinion 18, the driving pinion 18 meshes with the driven bull gear 19, and the driven bull gear 19 is connected with rotating shaft 9 by chain.

[0031] Further, the speed reducer 15 is a two-stage pendulum speed reducer with an extended shaft.

[0032] It should be noted that, the gear transmission system is adopted, the transmission box tensioning device of the prior art is canceled, the transmission device 13 is simplified, and the moving parts are reduced; the straight toot...

Embodiment 3

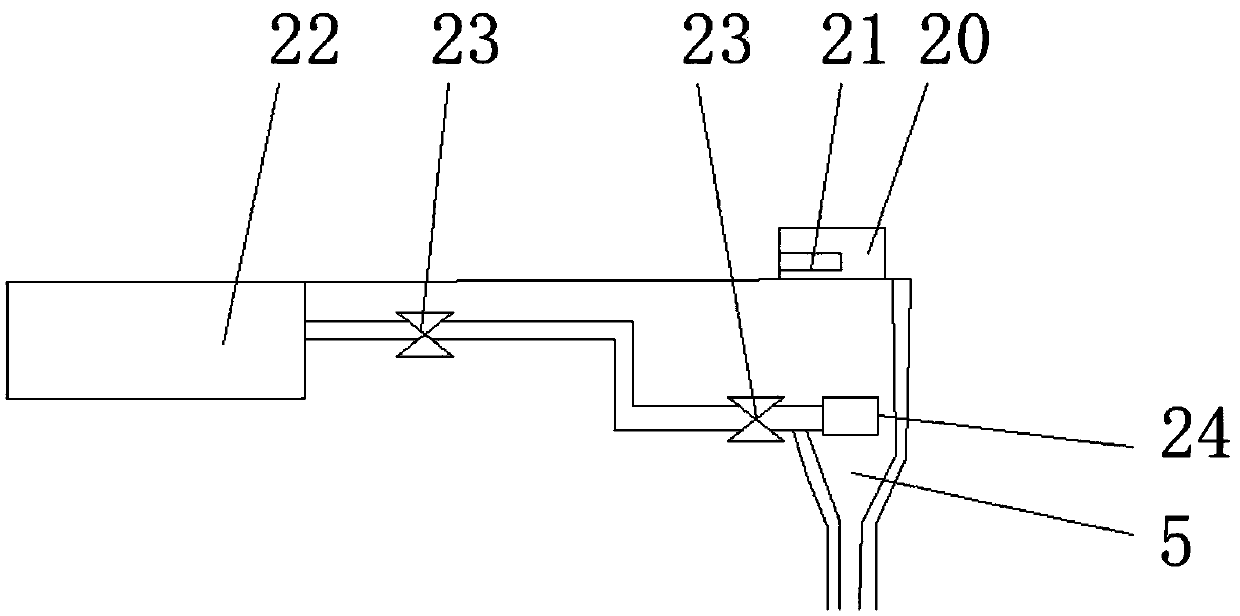

[0034] Such as Figure 1-3 Shown, a kind of leaching machine, feeding port 5 places are provided with sight glass 20, and the side near sight glass 20 in feeding port 5 is provided with sight glass cleaning device, and sight glass cleaning device comprises siphon big rinsing box 22, Valve 23 and shower nozzle 24, the water outlet of siphon large rinse tank 22 is connected with shower nozzle 24 by water pipe, the water outlet place of siphon large rinse tank 22 and the water inlet place of shower nozzle 24 are all provided with valve 23, and shower nozzle 24 is arranged on Below the mirror 20.

[0035] Further, a scraper 21 is provided on the viewing mirror 20 .

[0036] The feed port 5 is provided with a sight glass 20, which is convenient for the staff to observe the inside of the feed port 5, but the inner wall of the sight glass 20 is often stuck with some meal powder and dust, which will affect the operation of the leaching machine. It is inconvenient. By installing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com