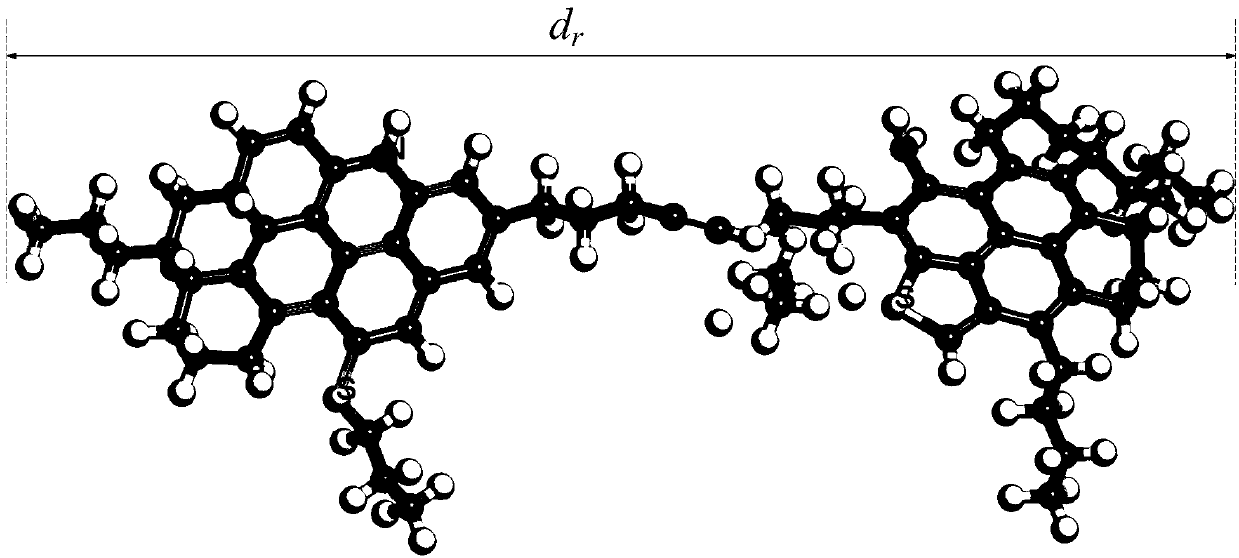

Method for adjusting and controlling heavy oil molecular structure

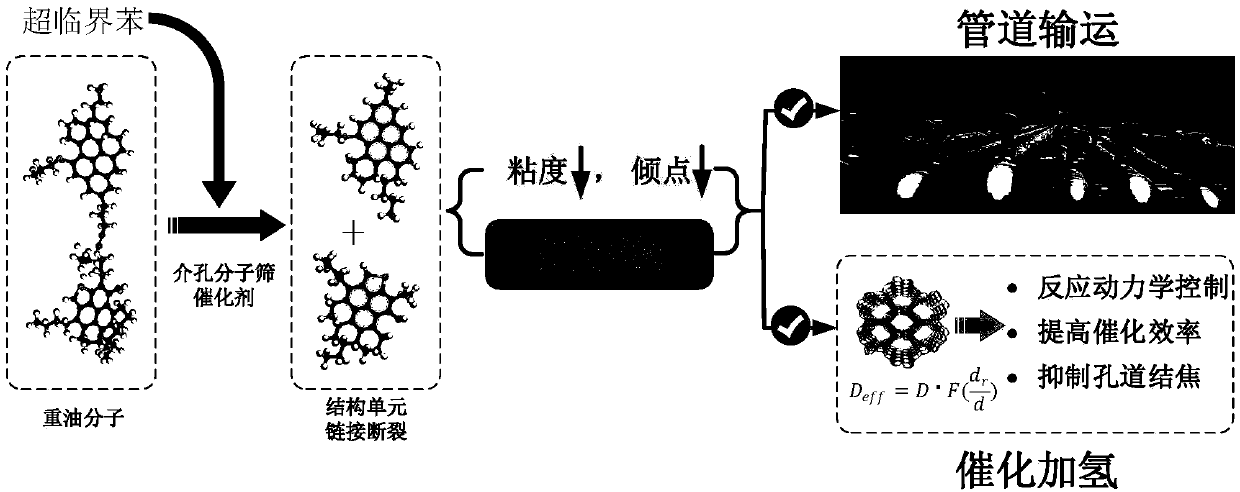

A molecular structure, heavy oil technology, applied in the petroleum industry, cracking, catalytic cracking, etc., can solve problems such as unfavorable catalytic cracking and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

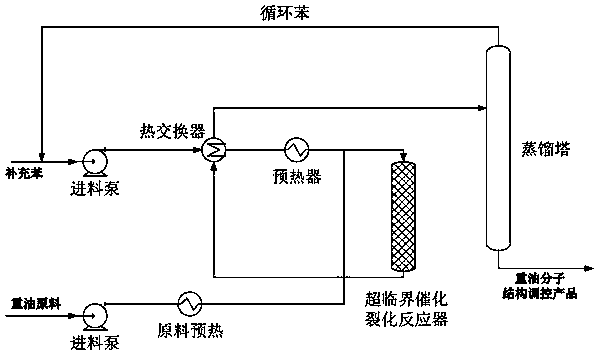

Method used

Image

Examples

Embodiment 1

[0035] The raw material of heavy oil is oil sand bitumen, and its basic properties are shown in Table 1. The mesoporous MCM-41 molecular sieve catalyst was purchased from the market.

[0036] Table 1 Basic properties of raw oil sand bitumen and FCC products

[0037]

[0038] Reaction process: 10g of oil sand pitch, mesoporous MCM-41 molecular sieve catalyst, and 30g of benzene were placed in an autoclave with a volume of 100ml. through N 2 After purging, the autoclave was closed and the temperature was raised at a rate of 15 °C / min. After reaching the cracking temperature of 390°C, maintain it for 0.5 min, and then quickly cool down the reaction system.

[0039] Product analysis: Four-component separation is based on the standard SY / T 5119-2016; the dynamic viscosity of the product is measured on the Advanced Rheology Expand System (TA Instruments); the number average molecular weight of the product is based on the Sinopec standard SH / T 0583-94 measurement; the distill...

Embodiment 2

[0045] The heavy oil raw materials are Changling reduced residue, Qingdao reduced residue and Tahe normal residue, and their basic properties are shown in Table 2. The catalyst is a mesoporous ZSM-5 molecular sieve, and the preparation method refers to "Preparation and catalytic application of ZSM-5 zeolite molecular sieve with mesoporous structure" (Jilin University Journal Science Edition, 2018, 56, 1561).

[0046] Table 2 Basic Properties of Atmospheric and Vacuum Residue Raw Materials and FCC Products

[0047]

[0048] Reaction process: After preheating the raw material residue and benzene, they pass through a fixed-bed reactor filled with mesoporous ZSM-5 molecular sieves. The mass ratio of raw material benzene and residual oil is 2:1 (wt), and the temperature when entering the catalyst bed is 370°C. The temperature of the catalyst bed was kept at 370° C., and the residence time of the material in the catalyst bed was 5 minutes. The density of supercritical benzene i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com