Non-toxic long-acting solvent-free drinking water cabin paint and preparation method thereof

A solvent-free, drinking water tank technology, used in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as poor anti-corrosion performance, and achieve the effects of high adhesion, long maintenance cycle, and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

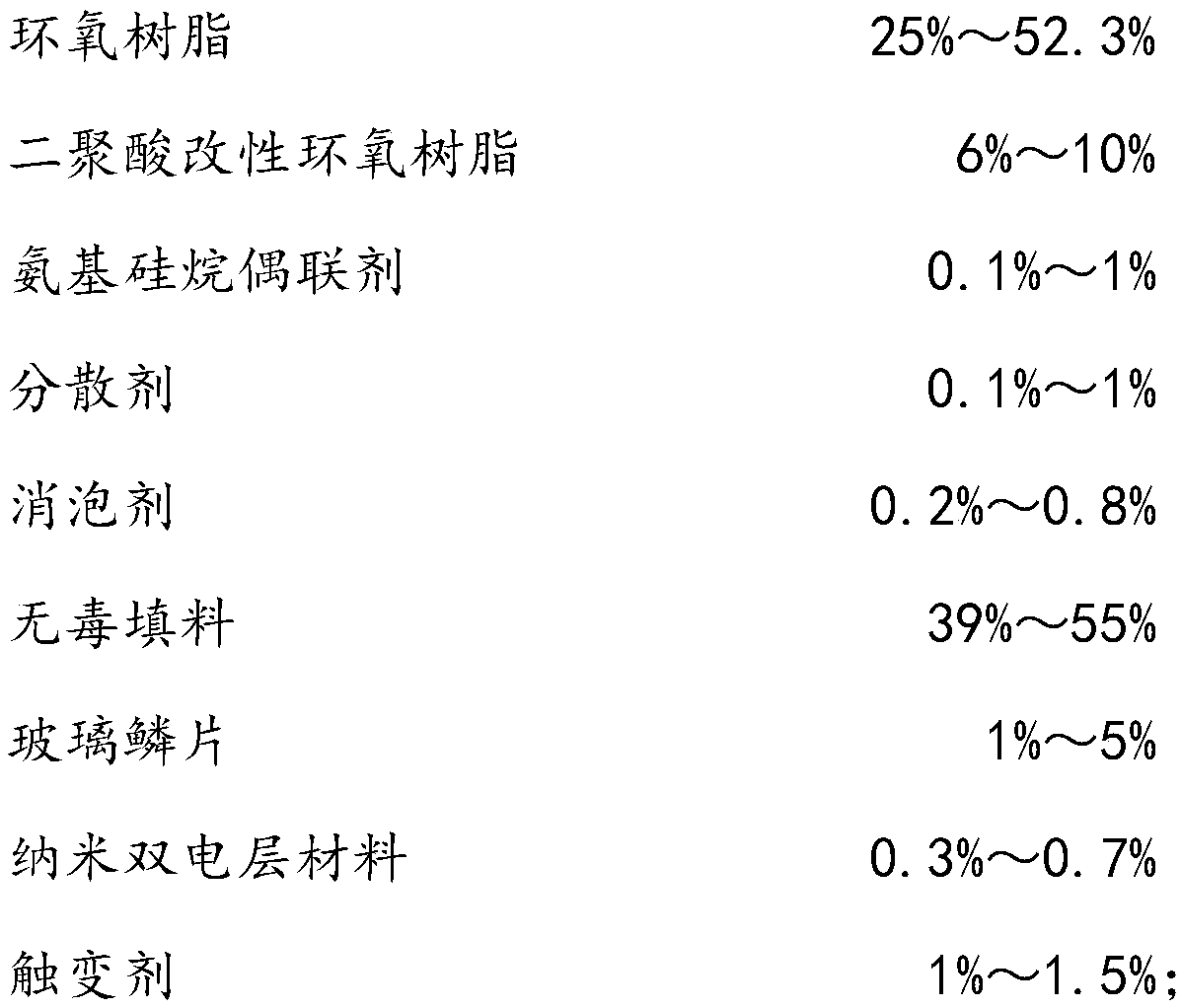

Method used

Image

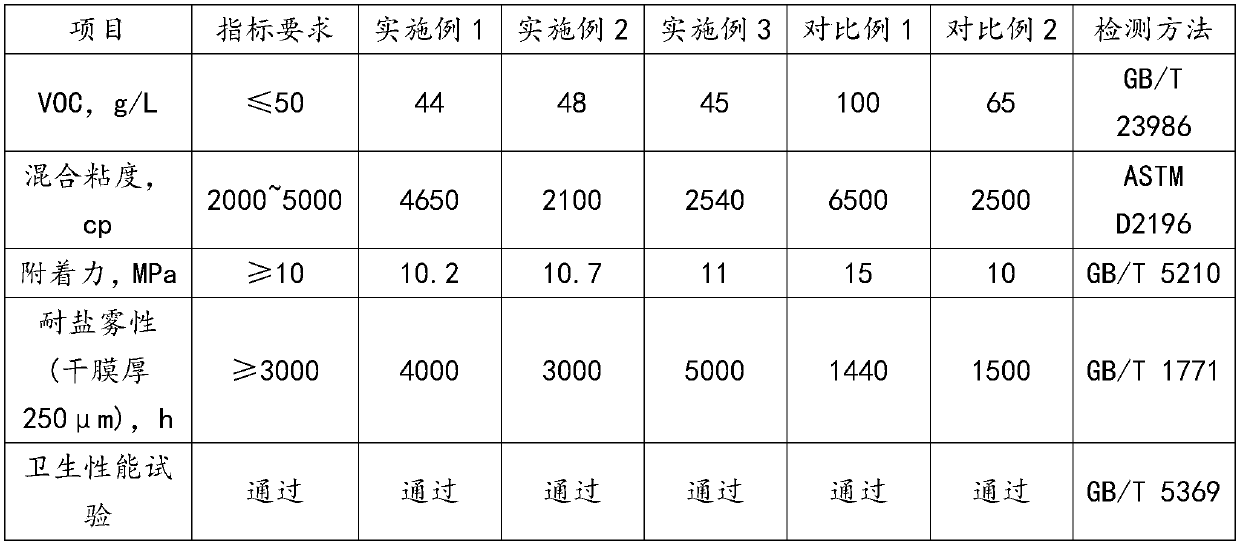

Examples

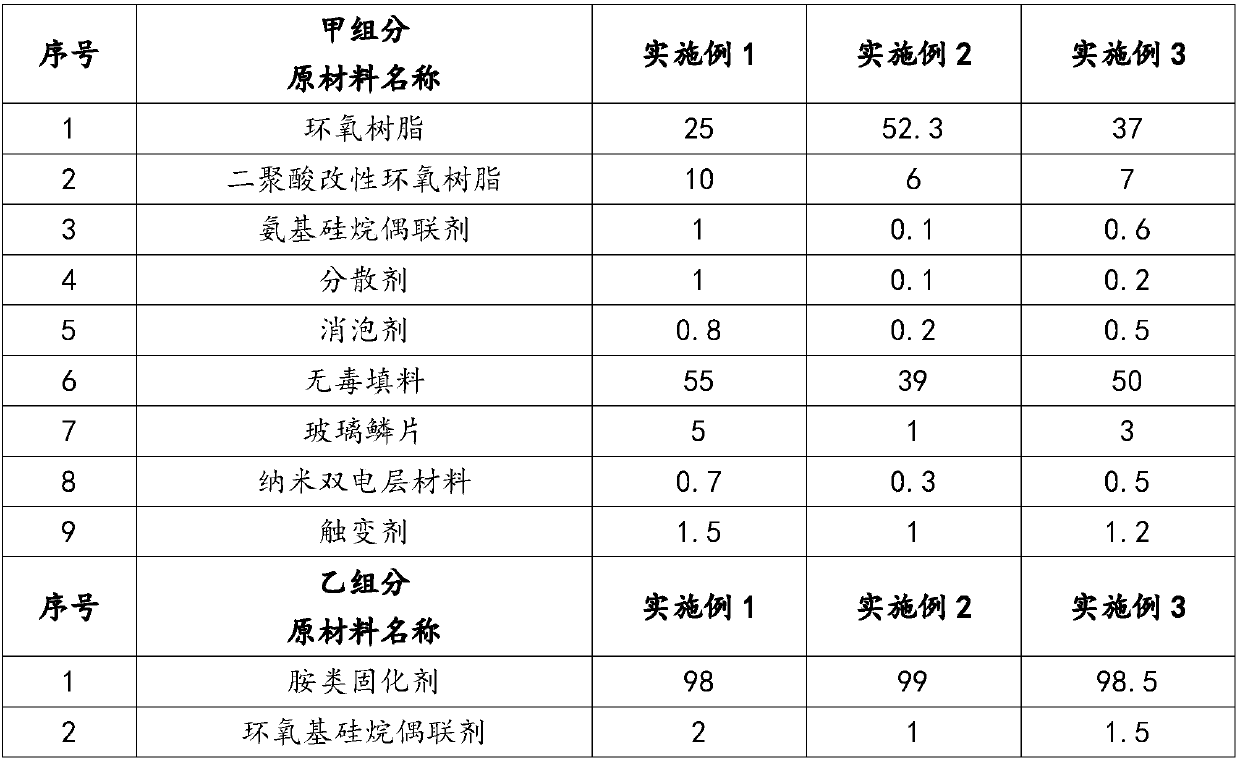

Embodiment 1

[0044] The dispersant in Example 1 is BYK110, the dispersant in Example 2 is BYK112, and the dispersant in Example 3 is BYK163;

[0045] The thickness of the glass flakes is 1-4 μm, and the size of the flakes is 50-300 μm;

[0046] Embodiment one thixotropic agent is attapulgite, embodiment two thixotropic agents are polyamide wax, embodiment three thixotropic agents are polyethylene wax;

[0047] The defoamer of embodiment 1 is silicone oil, the defoamer of embodiment 2 is BYKA530, and the defoamer of embodiment 3 is BYK023;

[0048] The non-toxic filler of embodiment one is talcum powder, the non-toxic filler of embodiment two is titanium dioxide, and the non-toxic filler of embodiment three is mica powder;

[0049] Embodiment one amine curing agent is phenalkamine, embodiment diamine curing agent is aliphatic amine, and embodiment triamine curing agent is alicyclic amine;

[0050] The epoxy silane coupling agent is KH-560.

[0051] According to the proportioning of raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com