Ion beam polishing process parameter determination method for six-axis motion polishing system

A technology of process parameters and ion beams, applied in the field of precision manufacturing, can solve problems such as time-consuming, and achieve the effect of shortening time, saving costs and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

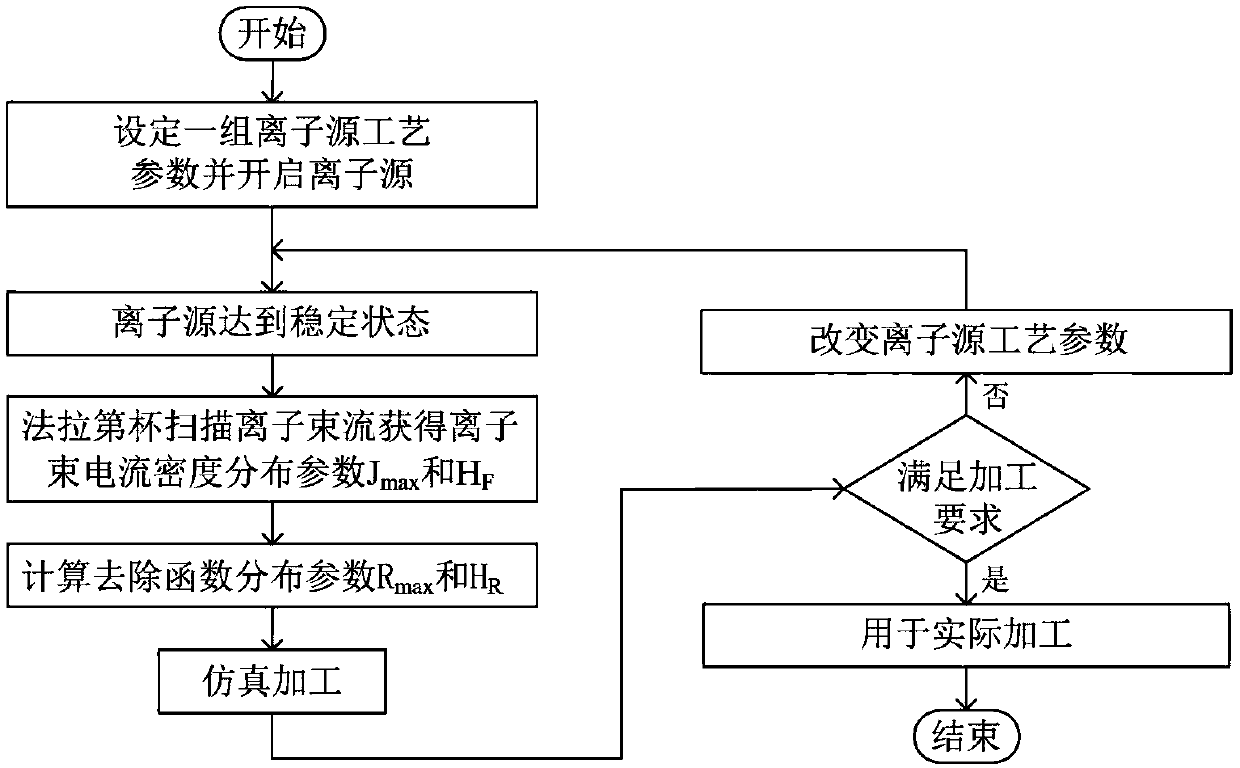

[0040] The specific operation process of a method for determining the removal function of ion beam polishing for a six-axis motion polishing system of the present invention is as follows:

[0041] (1) Determine the removal function:

[0042] 1. Turn on the six-axis motion polishing system power supply, water cooling device, working argon gas, etc.

[0043] 2. Place the optical components and fix the optical components in the middle of the base plate with clamps or high-temperature tape.

[0044] 3. Vacuumize to ensure the vacuum state of the experiment. Pump up the main vacuum chamber first, wait until the pressure of the vacuum chamber reaches 5.0×10 -1 At Pa, the secondary vacuum chamber is evacuated until the pressure of the secondary vacuum chamber reaches 2.5×10 -1 At Pa, transport the optics to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com