Method for machining tool billet

A technology for processing knives and billets, applied in the field of tool processing, can solve the problems of high production cost, increase the cost of steel raw materials, increase production cost, etc. produced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The following examples further illustrate the present invention.

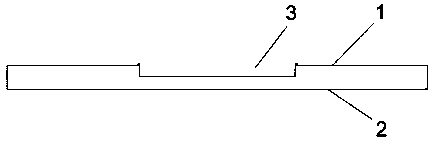

[0046] Combine Figure 1-Figure 3 It can be seen that in the prior art substrate, after the substrate and the high-speed steel bar 6 are welded, it is necessary to plan the blade first and then cut, or cut first and then plan the blade. In order to improve efficiency, the method of planing the blade and then cutting is often adopted. During the planing process, more parts need to be removed. One is the waste of steel, a large amount of metal waste is produced, and production costs such as labor, machinery and electricity are increased.

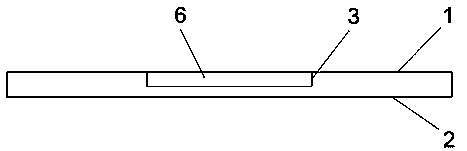

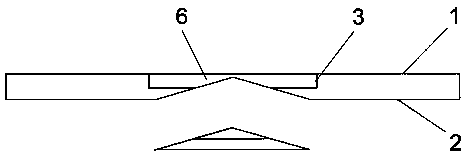

[0047] Combine Figure 4-Figure 7 It can be seen that the method for processing tool blanks of the present invention includes the following steps:

[0048] (1) Production of the substrate. The upper surface 1 of the substrate is provided with an inlay groove 3, which fixes the high-speed steel bar 6; the depth of the inlay groove 3 is equal to the thickness of the high-speed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com