Automatic pressing device for single-head sealing of packaging cans

A technology of pressing device and tank, which is applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of unsustainable operation, limited operation output, low efficiency, etc., and achieve saving manpower and material resources, strong adaptability, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

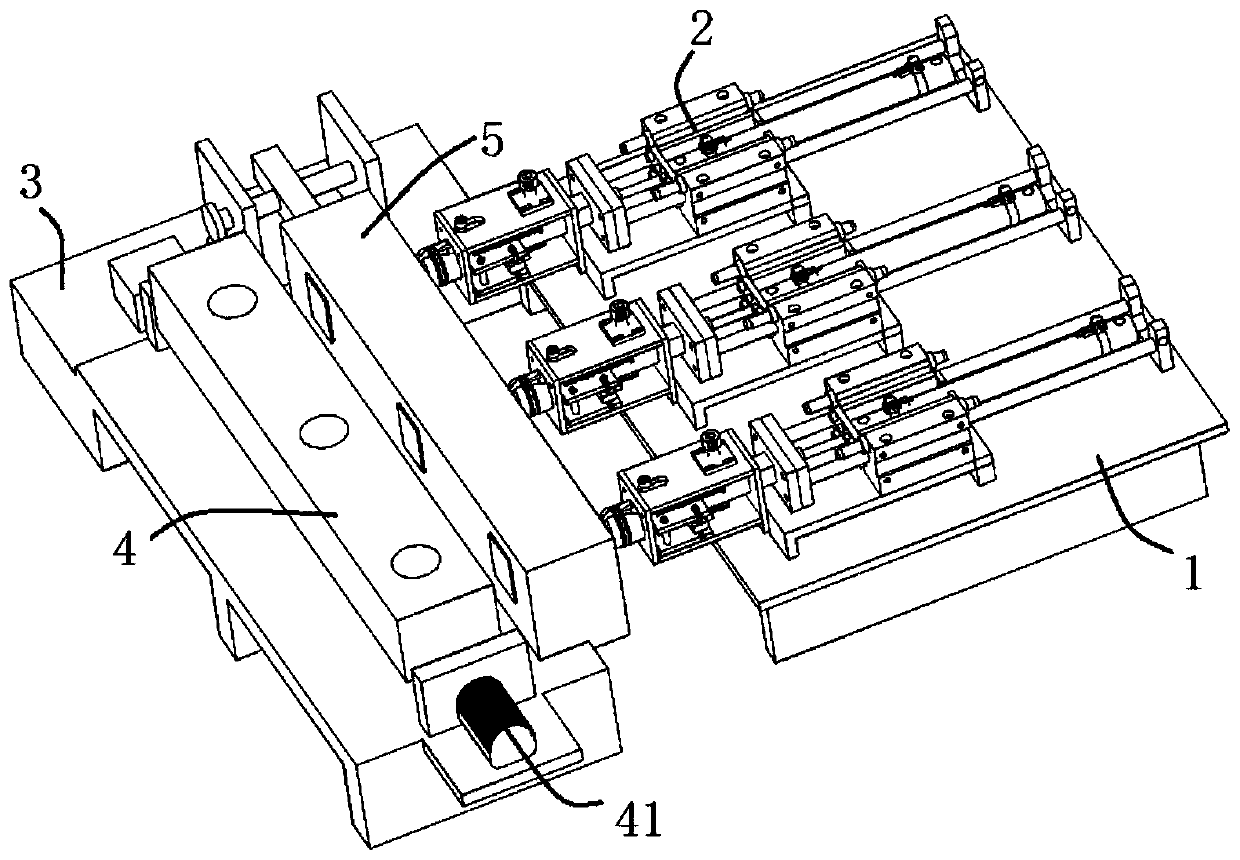

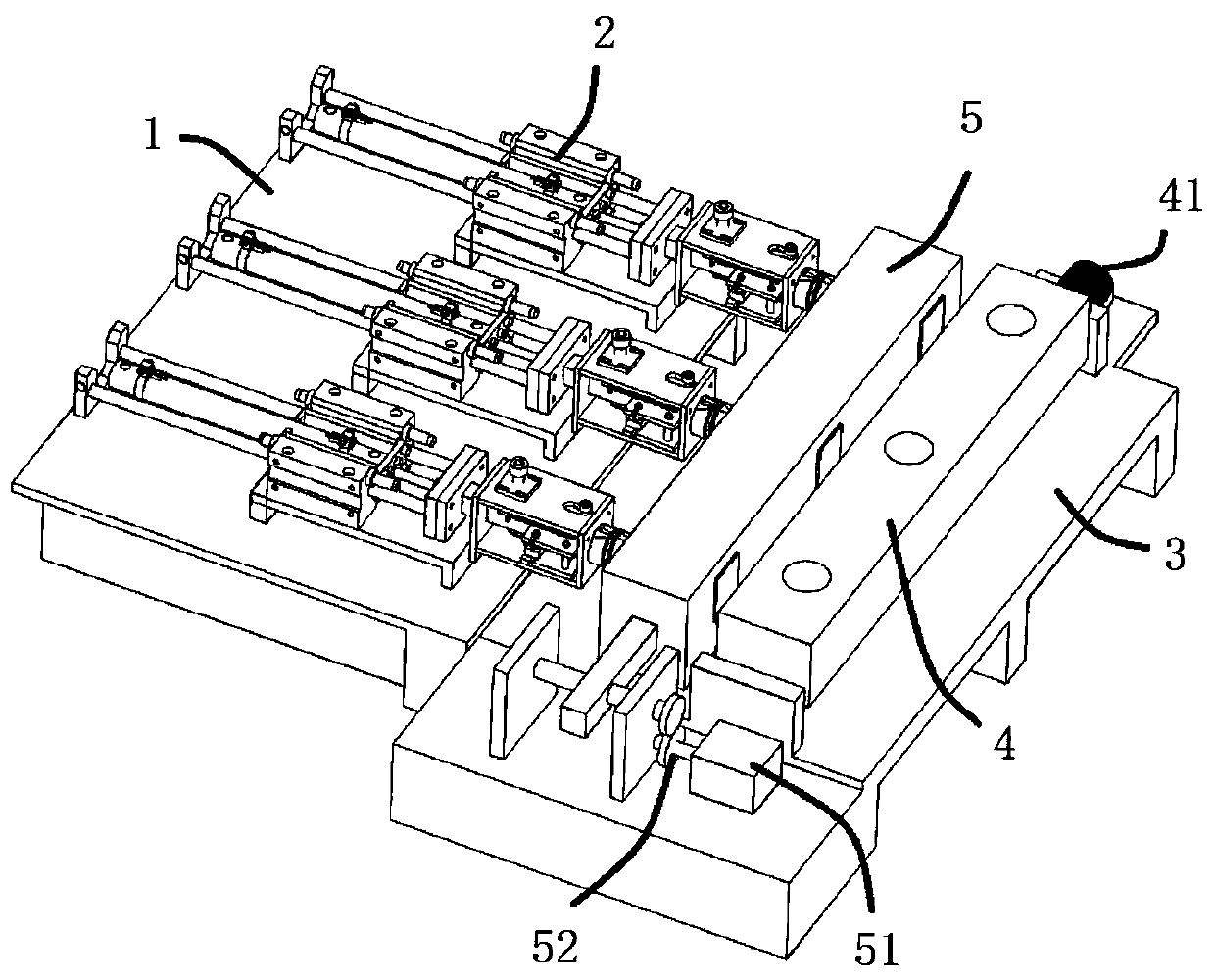

[0029] see figure 1 , figure 2 , image 3 , Figure 4 as well as Figure 5 , an automatic pressing device for single-head sealing of packaging tanks, including a base 1, a feeding and unloading mechanism 2, a tank body transfer mechanism and a capping alignment mechanism;

[0030] The base 1 is in the shape of a flat plate, and there are a plurality of said retrieving and unloading mechanisms distributed in parallel on the base 1, and said tank body transfer mechanism is provided in the gap at the front end side of the retrieving and unloading mechanism. The gap between the feeding and unloading mechanism and the tank body transfer mechanism is provided with the above-mentioned cover alignment mechanism;

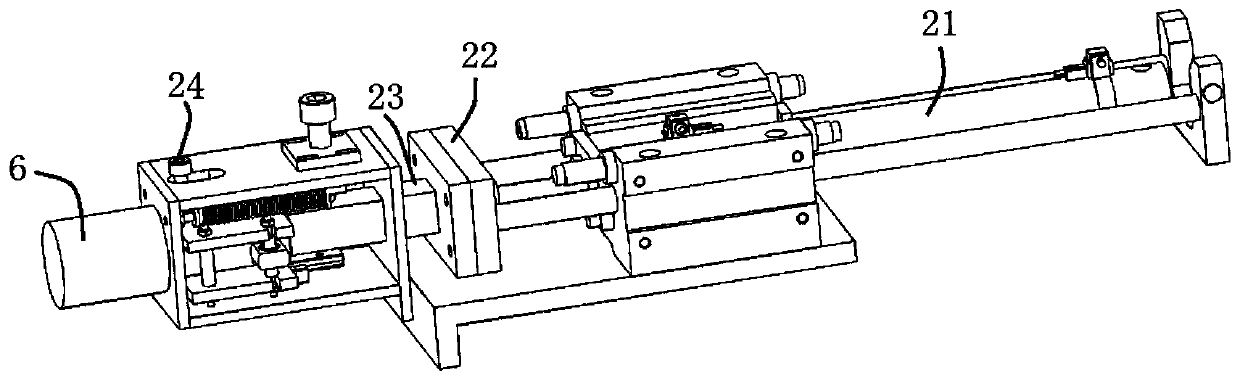

[0031] Described take-up and unloading mechanism 2 contains driving part 21, and the extension end of driving part 21 is connected with tensioning head 27; The top surface is provided with a placement slot corresponding to the feeding and unloading mechanism distribute...

Embodiment 2

[0040] A guide frame 291 is slidably provided on the slide rail 29, and two spacer plates are longitudinally and parallelly arranged on the top surface of the guide frame 291, and the pressing rod 232 is slidably arranged in the chute formed by the two spacer plates. A receiving groove is recessed on the top surface of the pressing rod 232 , the bottom end of the limiting column 24 is fixedly connected to the bottom surface of the receiving groove, and the return spring 231 is located in the receiving groove. All the other structures are with embodiment 1.

Embodiment 3

[0042] The transmission mechanism includes a driving gear 52 and a driven gear, wherein the driving gear 52 is coaxially fixed on the motor shaft of the rotating motor 51, and the driven gear is coaxially fixed on the extended end of the third rotating shaft. And the driving gear 52 meshes with the driven gear. All the other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com