Room temperature spinning forming method of hard-to-deform nickel-based superalloy composite curved busbar components

A nickel-based high-temperature alloy, spinning forming technology, applied in the field of plastic forming of metal materials, to achieve the effect of precise forming, material cost reduction, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

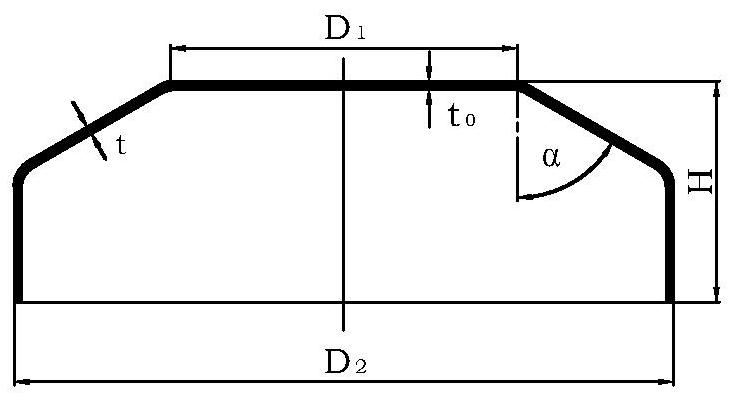

[0035] figure 1 It is a schematic diagram of a kind of hard-to-deform nickel-based superalloy cone-tube composite curved busbar component. Its material is Haynes230 nickel-based superalloy. 1 =96mm, inner diameter of mouth D 2 = 176mm and the half cone angle of the tapered part is α = 60°.

[0036] According to the sine law of shear spinning, the original wall thickness of the blank is t 0 =t / sinα=2mm; the blank is a circular sheet, and according to the principle of volume invariance, through theoretical analysis and three-dimensional software drawing, and combined with a trimming allowance of 10mm, the diameter of the circular sheet is calculated to be 243mm.

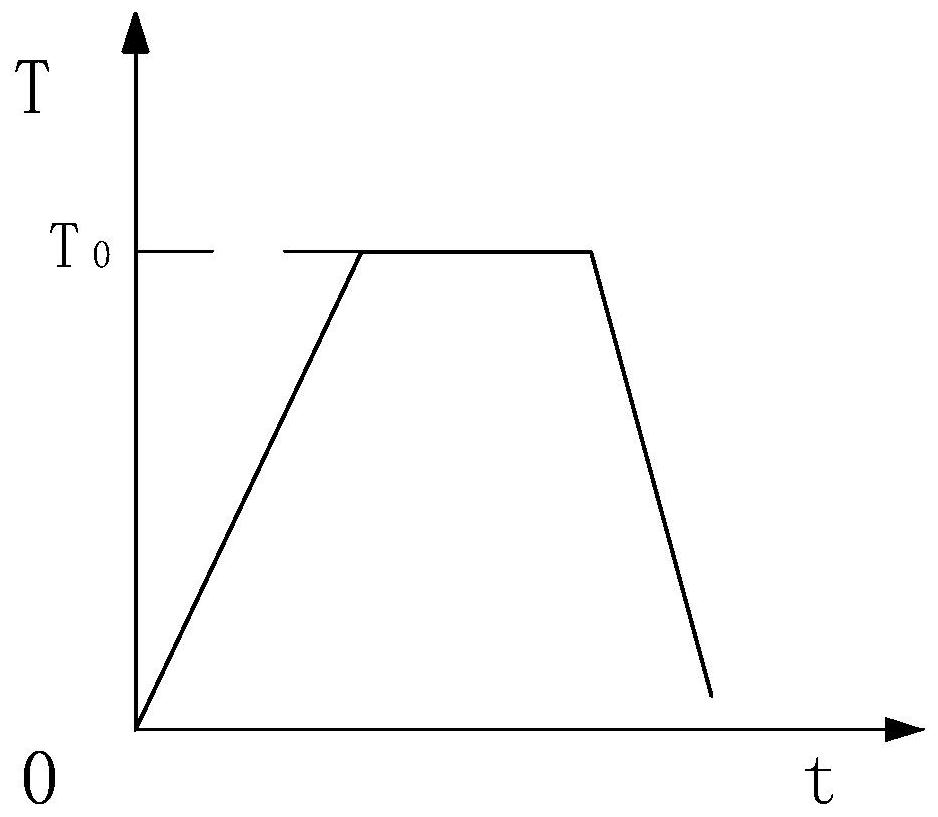

[0037] A-1. Put the blank into the heating furnace and raise the temperature to T at a rate of 10°C / s 0 = 1230°C for 60 minutes of heat preservation, and then water cooling out of the furnace, the temperature change during the heat treatment of the blank is as follows figure 2 shown.

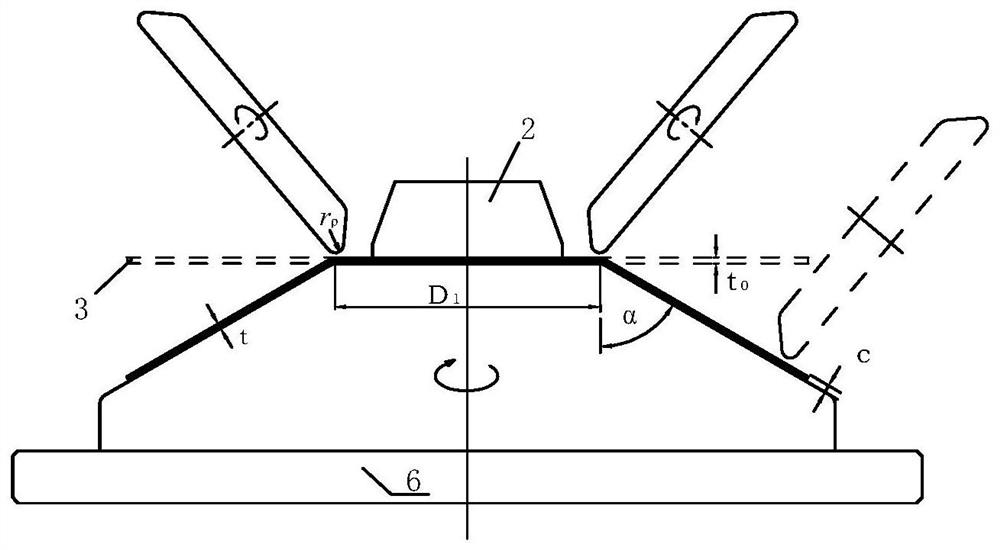

[0038] A-2. Schematic diagr...

Embodiment 2

[0045] Image 6 It is a schematic diagram of a hard-to-deform nickel-based superalloy tube-cone-tube composite curved busbar component. The material is Haynes230 nickel-based superalloy, and the wall thickness of the part tube is required to be t=2mm and the inner diameter of the bottom is D 1 =68mm, mouth inner diameter D 2 =200mm, cone half angle α 1 =60°, total part height H=80mm and mouth tube height H 1 = 30mm.

[0046] In order to ensure that the prefabricated conical part after shear spinning does not appear unstable and wrinkled during multi-pass general spinning, the prefabricated conical part is designed to be tangent to the rounded corner of the curved generatrix-shaped mandrel. According to the geometric relationship, the semi-cone angle during shear spinning can be obtained as α=arctan[(D 2 -D 1 ) / 2(H-H 1 )]=53°, and the wall thickness of the part remains unchanged after multi-pass ordinary spinning, so the wall thickness of the blank can be obtained as t 0 =...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com