Dual-drive single pendulum type sub-resonance vibration crushing machine

A dual-machine-driven, crusher technology, applied in grain processing and other directions, can solve the problems of uneven jaw plate wear, small crushing, discontinuous crushing, low efficiency, etc., to reduce operating costs, meet environmental protection, and improve crushing ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

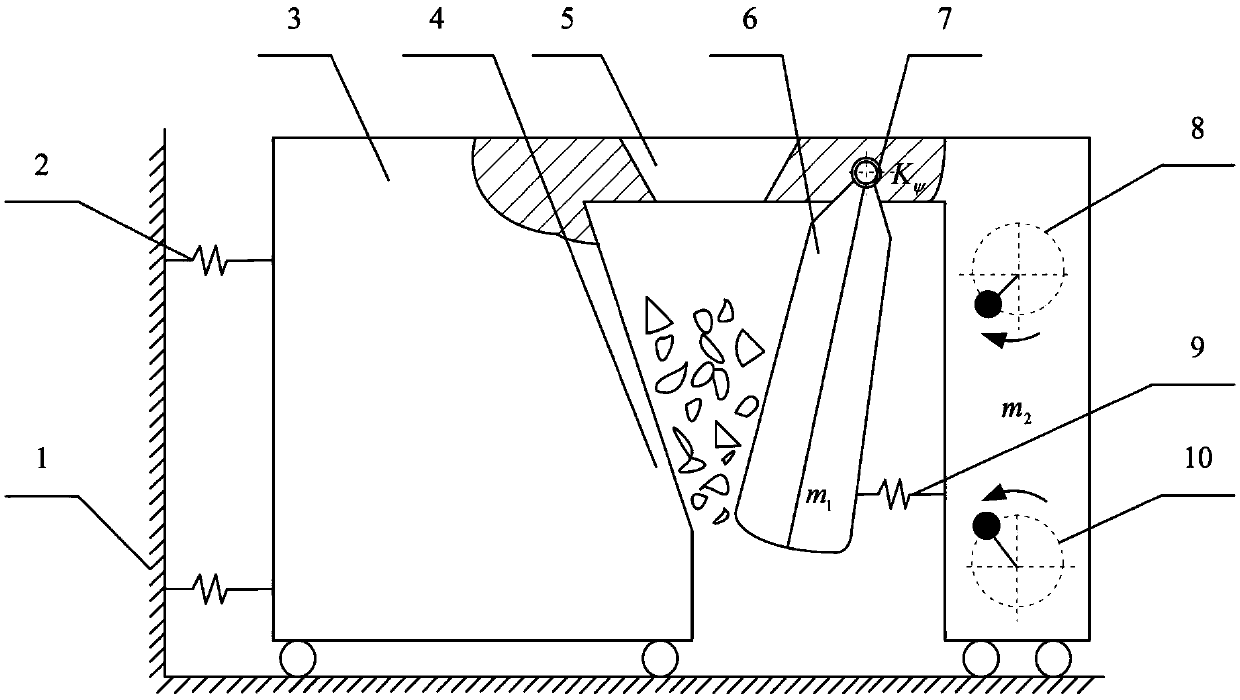

[0016] figure 1 Among them, the two exciters placed in the box mechanism 3 are installed symmetrically up and down, and an eccentric block is installed on each exciter, and the phase difference is synchronously stabilized at 0°. 6 phase connection. The movable jaw 6 is connected with the box mechanism 3 through the torsion spring 7, and the movable jaw 6 and the fixed jaw 4 are symmetrically installed about the center axis of the box mechanism 3 left and right. The left side of the torsion spring 7 is the feeding port 5, and there are four vibration isolation springs 2, which are installed on the left side of the box mechanism 3 front, rear, left, and right, and the box mechanism 3 is installed on the frame 1. Wherein frame 1 is made by channel steel and steel plate welding.

[0017] Define the phase difference of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com