Three-dimensional mesoporous carbon-loaded molybdenum carbide and preparation method and application thereof

A three-dimensional mesoporous and molybdenum carbide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as increased d energy band density, and achieve prevention of agglomeration and multiple reactive active sites , the effect of excellent electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] A preparation method of a three-dimensional mesoporous carbon-supported molybdenum carbide in this embodiment, the specific preparation steps are as follows:

[0050] Dissolve 6.0 g of soluble ammonium molybdate in deionized water, then add 15.0 g of diammonium hydrogen citrate, and add 40 g of silicon dioxide dispersion (silicon dioxide content 40wt%, silicon dioxide particle size 15 ± 5nm) after the dissolution is complete , then use ammonia water to adjust the pH of the above solution to 6.0, then stir and evaporate to dryness at 70°C for 12 hours to obtain a gel, then dehydrate the gel at 200°C for 12 hours to obtain a xerogel, grind the xerogel evenly, and put Put into a tube furnace at 900°C for carbon reduction for 2 hours, and feed 5% (v / v) H during the reaction process 2 / Ar mixed gas, soak and stir with excess 4.0wt% hydrofluoric acid for 4 hours after the reaction, filter, and dry naturally to obtain the target product three-dimensional mesoporous carbon-supp...

Embodiment 2

[0054] A preparation method of a three-dimensional mesoporous carbon-supported molybdenum carbide in this embodiment, the specific preparation steps are as follows:

[0055] Soluble sodium molybdate 6.0g is dissolved in deionized water, then add 20.0g cyanamide, add 40g silicon dioxide dispersion liquid (40wt% of silicon dioxide content, silicon dioxide particle diameter 15 ± 5nm) after dissolving completely, use Adjust the pH of the above solution to 7 with nitric acid, then stir and evaporate to dryness at 70°C for 12 hours to obtain a gel, then put the gel into a tube furnace for carbonization and reduction at 700°C for 2 hours, and feed 5% (v / v) H 2 / Ar mixed gas, soak and stir with excess 2.0wt% hydrofluoric acid for 8 hours after the reaction, filter, and dry naturally to obtain the target product three-dimensional mesoporous carbon-supported molybdenum carbide.

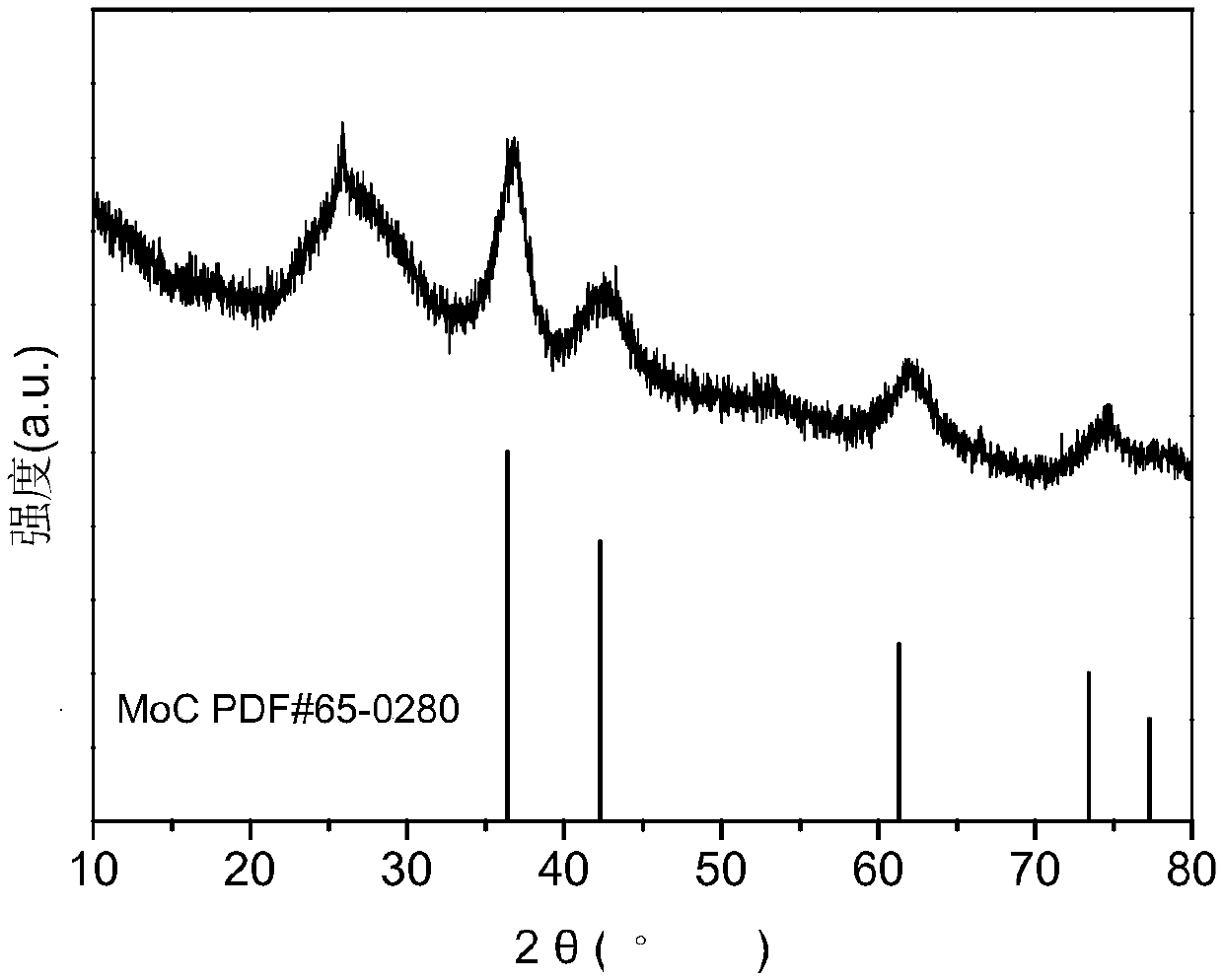

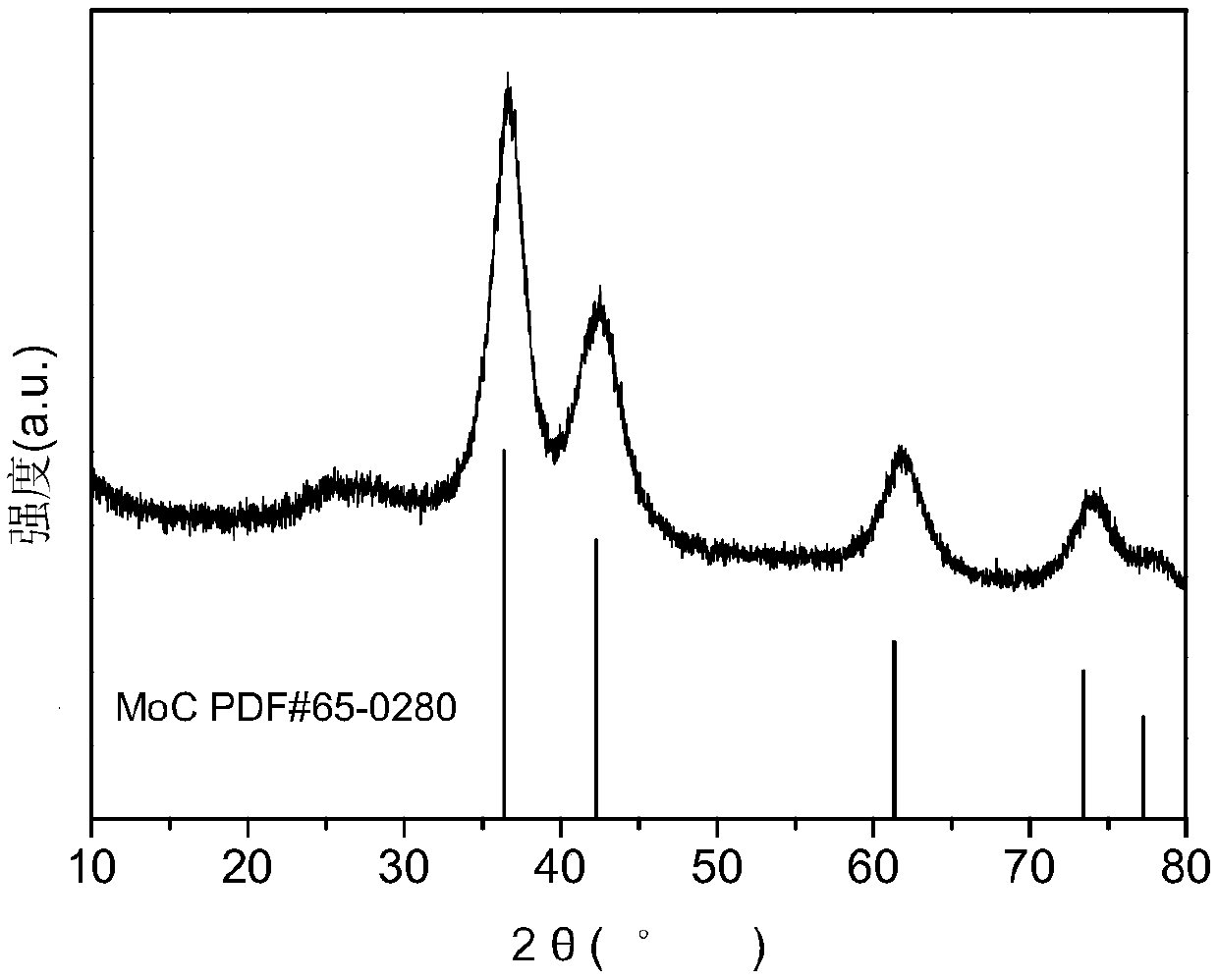

[0056] The XRD pattern of the three-dimensional mesoporous carbon supported molybdenum carbide obtained in...

Embodiment 3

[0059] A preparation method of a three-dimensional mesoporous carbon-supported molybdenum carbide in this embodiment, the specific preparation steps are as follows:

[0060] Dissolve 6.0 g of soluble ammonium molybdate in deionized water, then add 18.0 g of dicyandiamide, and add 40 g of silica dispersion (40 wt % silica content, 15 ± 5 nm in silica particle size) after dissolving completely, Use nitric acid to adjust the pH of the above solution to 4.5, then stir and evaporate to dryness at 80°C for 12 hours to obtain a gel, then dehydrate the gel at 180°C for 12 hours to obtain a xerogel, grind the xerogel evenly, and put it in a tube 900°C carbonization and reduction in a type furnace for 2 hours, and 10% (v / v) H was introduced during the reaction. 2 / Ar mixed gas, soak and stir with excess 4.0wt% hydrofluoric acid for 2 hours after the reaction, filter, and dry naturally to obtain the target product three-dimensional mesoporous carbon-supported molybdenum carbide.

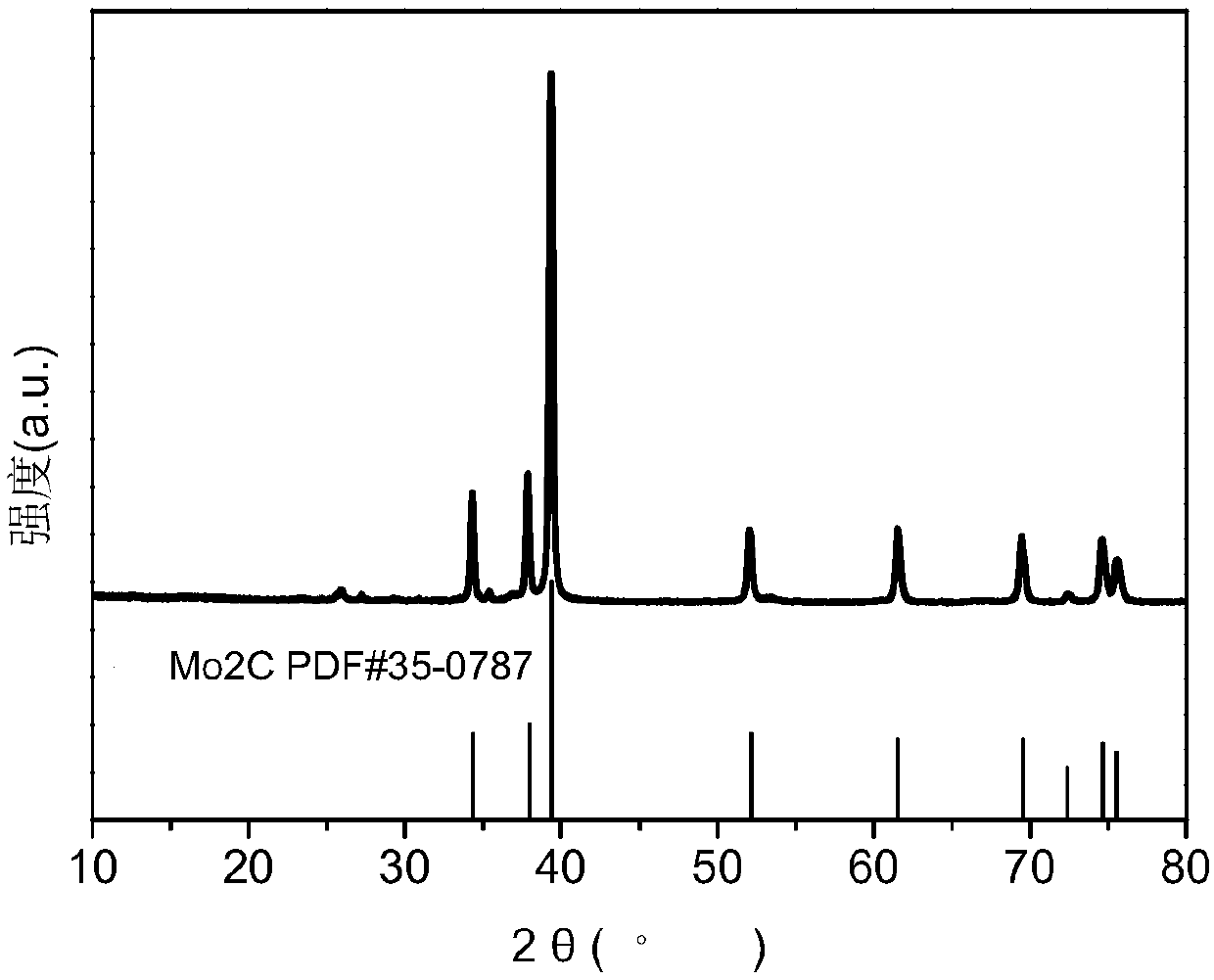

[0061...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com