Industrial preparation method of instant puffed rice

A production method, the technology of soaking rice crackers, applied in the direction of food science, etc., can solve the problems of loss of nutrients, inconvenient eating, rough taste, etc., and achieve the effect of easy absorption, convenient eating, and rich content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

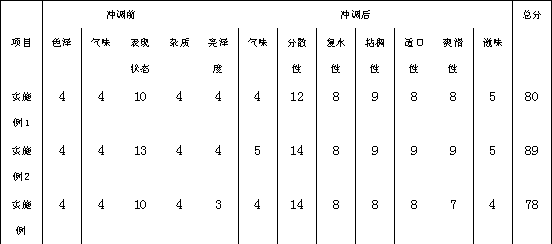

Examples

Embodiment 1

[0035] An industrial production method for instant soaked rice crackers, which includes the following components by weight: 12 parts of Zhongjiazao 17 brown rice, 10 parts of Zhongzao 39 brown rice, 2 parts of Ruanhuayou 6100 brown rice, and 5 parts of germ rice;

[0036] The preparation method of described instant bubble rice flower is:

[0037] S1. Raw material selection: Fresh Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice, and germ rice are selected and removed respectively, and the processed Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice and germ rice are immediately treated by vacuum low-temperature preservation for standby. After fresh raw materials are sorted, they are immediately treated for freshness and anti-oxidation, and cold chain transportation makes the raw materials fresher, and the prepared ready-to-eat bubble rice has higher quality and better flavor;

[0038] S2. Low-temperature grinding: transpo...

Embodiment 2

[0046] An industrial production method of instant soaked rice crackers, which includes the following components by weight and ratio: 50 parts of Zhongzao 17 brown rice, 50 parts of Zhongzao 39 brown rice, 20 parts of Ruan Huayou 6100 brown rice, and 20 parts of germ rice;

[0047] The preparation method of described instant bubble rice flower is:

[0048] S1. Raw material selection: Fresh Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice, and germ rice are selected and removed respectively, and the processed Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice and germ rice are immediately treated with nitrogen and then kept fresh at low temperature for later use. After fresh raw materials are sorted out, they are immediately treated with fresh-keeping and anti-oxidation treatment, and cold chain transportation makes the raw materials fresher, and the prepared ready-to-eat bubble rice has higher quality and better flavor. it...

Embodiment 3

[0057] An industrial production method of instant soaked rice crackers, which includes the following components by weight and ratio: 95 parts of Zhongjiazao 17 brown rice, 80 parts of Zhongzao 39 brown rice, 35 parts of Ruanhuayou 6100 brown rice, and 75 parts of germ rice;

[0058] The preparation method of described instant bubble rice flower is:

[0059] S1. Raw material selection: Fresh Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice, and germ rice are selected and removed respectively, and the processed Zhongjiazao 17 brown rice, Zhongzao 39 brown rice, Ruanhuayou 6100 brown rice and germ rice are immediately treated with carbon filling and kept fresh at low temperature for later use. After the fresh raw materials are sorted, they are immediately treated with fresh-keeping and anti-oxidation treatment, and cold chain transportation makes the raw materials fresher, and the ready-to-eat soaked rice crackers prepared are of higher quality and mor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com